Method for stretching polymer film and device for recovering slit film edge

A technology of polymer film and recycling equipment, which is applied in metal processing and other fields, and can solve the problems of reducing the quality of TAC film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

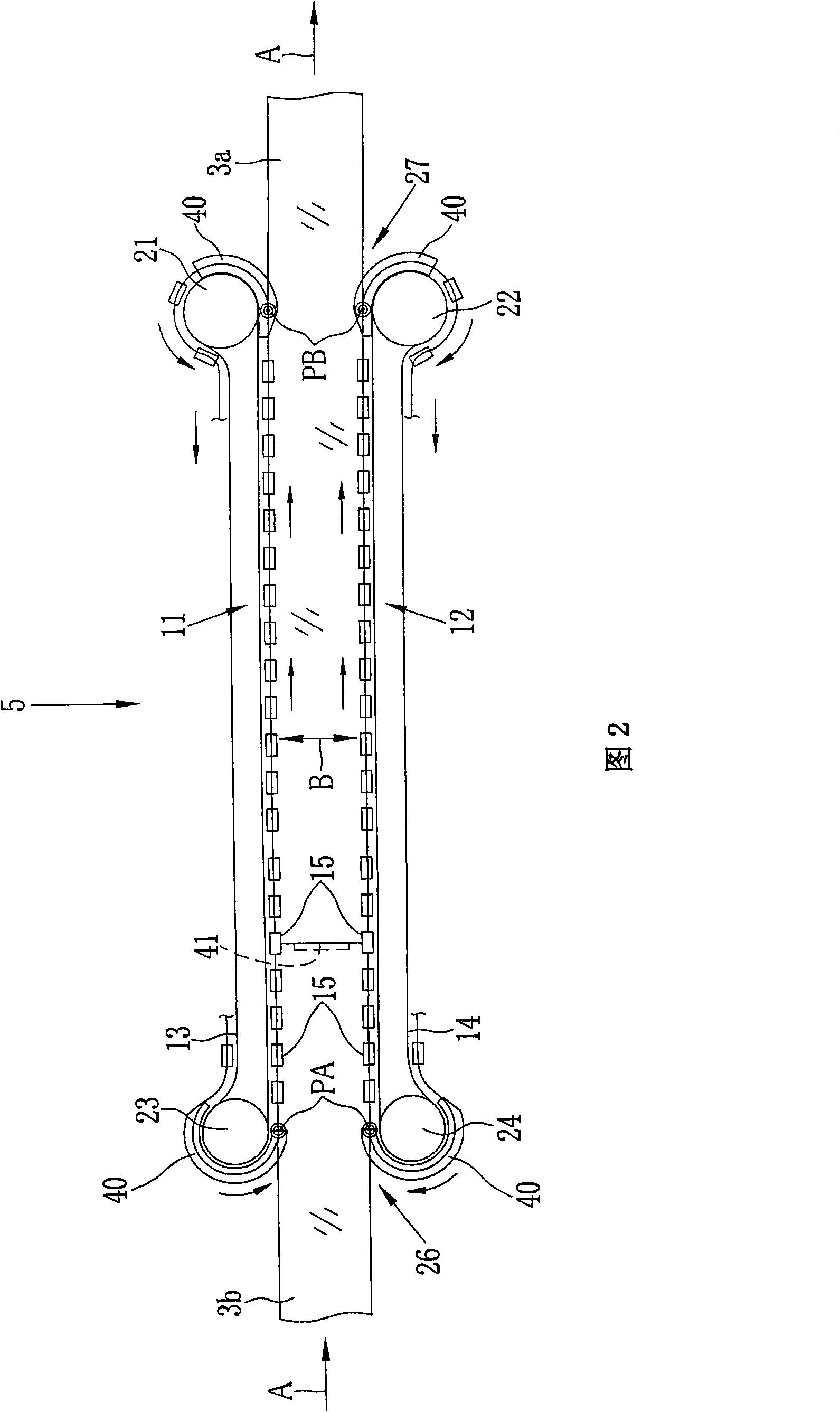

[0020] As shown in FIG. 1 , an offline stretching apparatus 2 is used to stretch a TAC film 3 , and is equipped with a supply chamber 4 , a tenter 5 , a stress relaxation chamber 6 using heating, a cooling chamber 7 , and a winding chamber 8 . The supply chamber 4 stores the TAC film 3 in roll form that has been produced in the solution casting line. The TAC film 3 is supplied to the tenter 5 through the supply roll 9 .

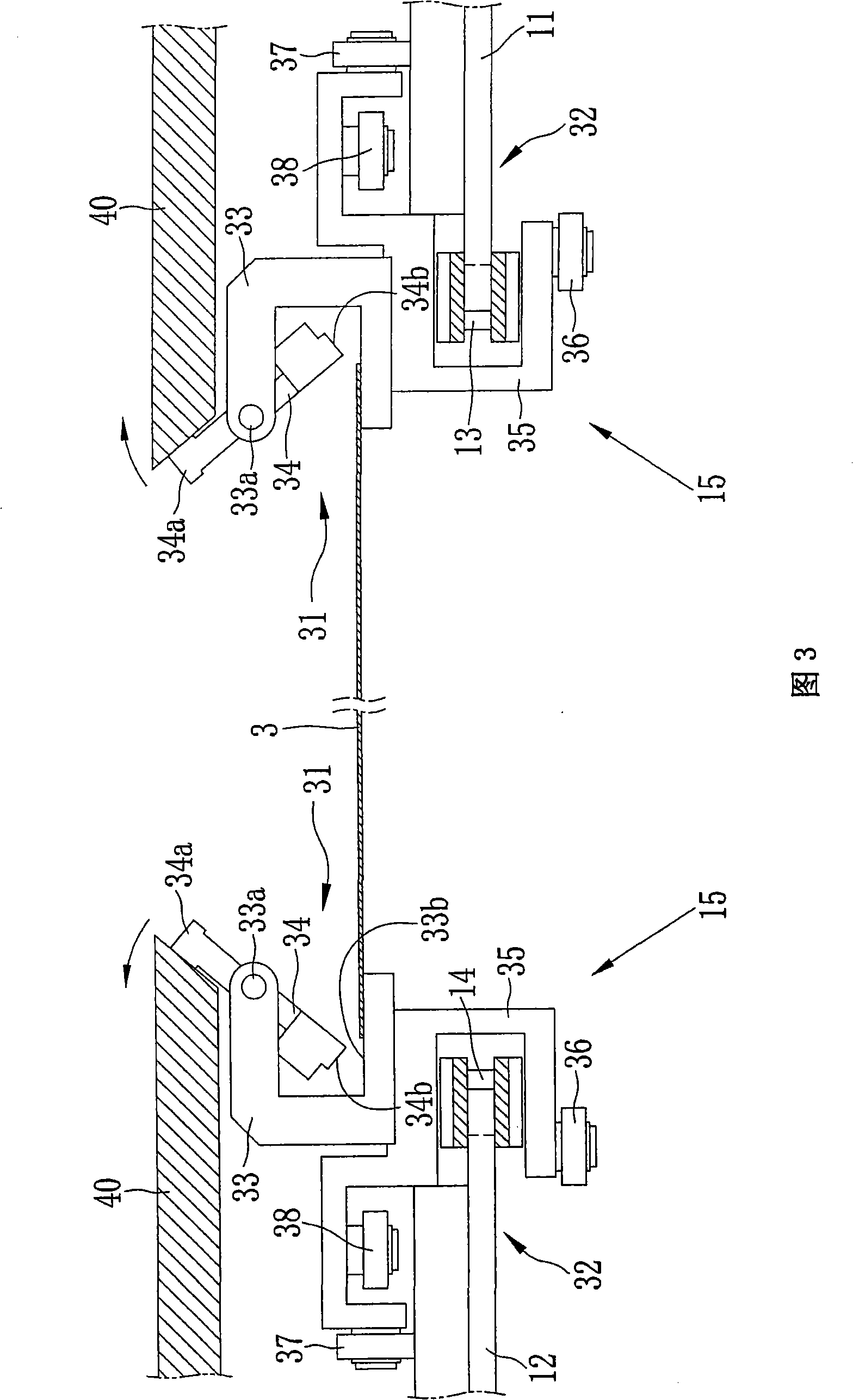

[0021] In the tenter 5, both sides of the TAC film 3 are held by clips 15 (see FIG. 2). While conveyed in this state, the TAC film 3 is heated and stretched in the film width direction B (see FIG. 2 ). The TAC film 3 is preferably stretched in the film width direction B by 100.5% to 300% relative to the width of the TAC film 3 before stretching.

[0022] The reservoir 10 is provided between the supply chamber 4 and the tenter 5 . In the reservoir 10, a certain length of the TAC film 3 remains to form a ring. The certain length is a length sufficient to co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap