Device for installing and regulating filtering material

A steel ring and skeleton technology, applied in the field of filter material installation and adjustment devices, can solve the problems of high manufacturing cost, difficulty in filter material expansion and tightening, affecting filter material roundness and dust collection effect, etc., to ensure roundness, Material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

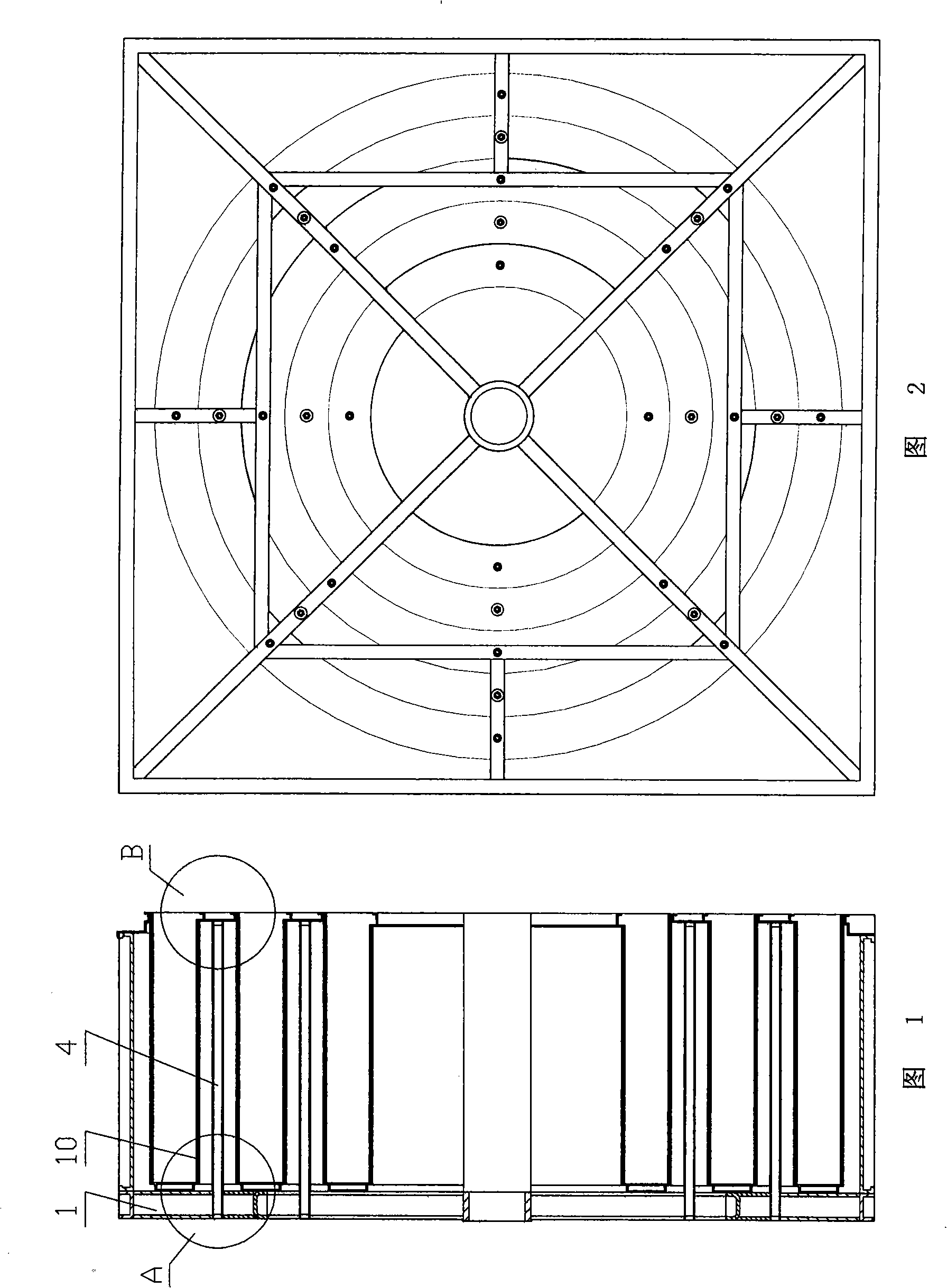

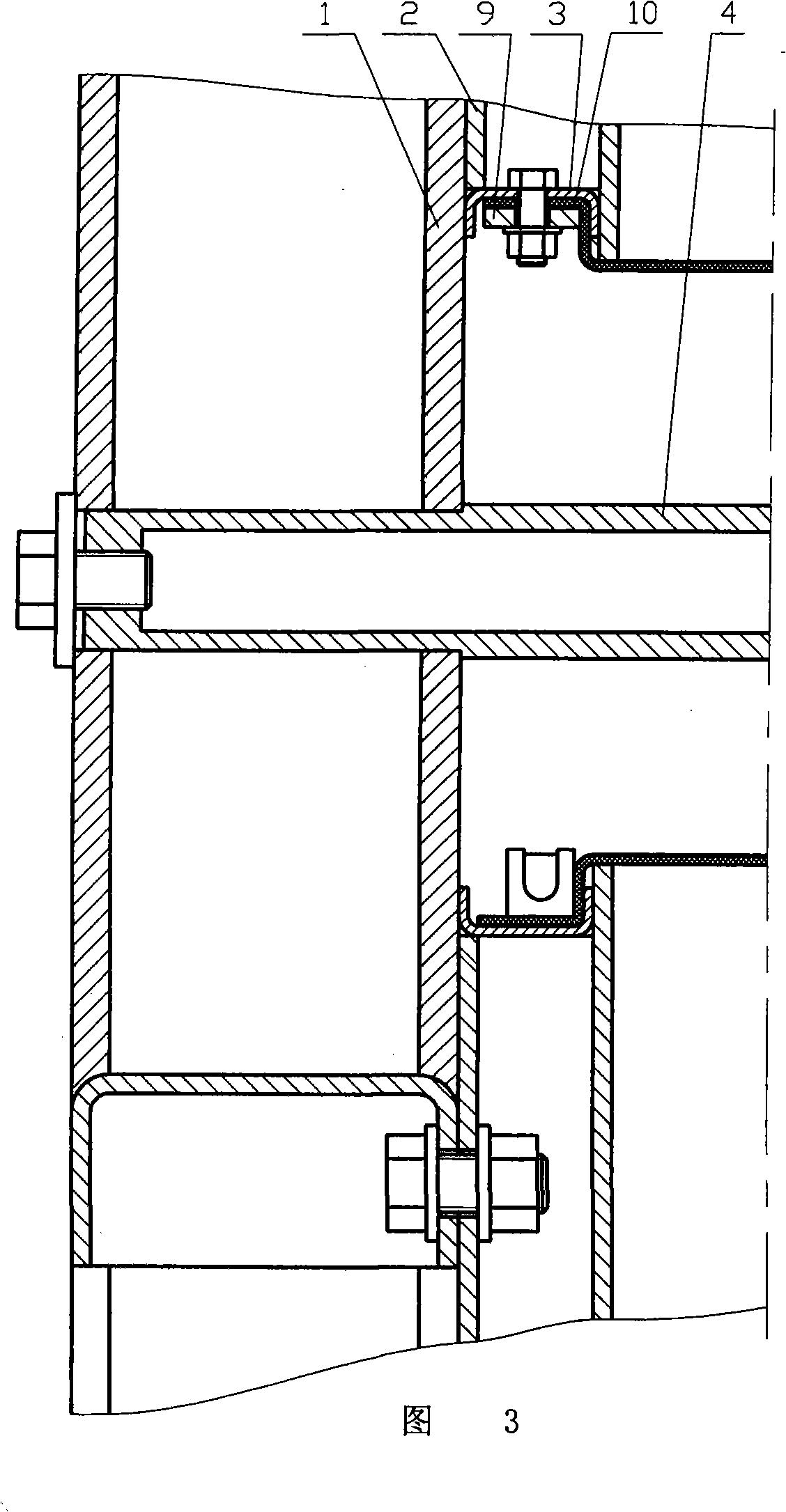

[0011] As shown in the drawings, the rear frame steel ring 2 is fixed to the frame 1, and the front frame steel ring 6 is set on the outer cylindrical surface of the "T"-shaped positioning nut 12 through the double-center eccentric ferrule 14, and the outer cylindrical surface of the positioning nut 12 is There are threads on it, and the locking nut 13 is screwed, and the front frame steel ring 6 and the double-center eccentric ferrule 14 can be locked with the positioning nut 12 by tightening the locking nut 13 . The bolt 5 is screwed with a positioning nut 12 and a locking nut 11, the locking nut 11 can lock the positioning nut 12 and the bolt 5, the bolt 5 and the right end of the steel pipe 4 are fixed by threads, and the left end of the steel pipe 4 is fixed to the frame 1 . The "U"-shaped steel rings 3 and 7 are respectively fixed on the rear frame steel ring 2 and the front frame steel ring 6, and the filter material 10 with a flexible lining net is connected to the "U"...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com