Tube winding machine and pipe membrane production equipment composed of the same

A technology of production equipment and tube rolling machine, applied in the field of film manufacturing, can solve the problems of food and drug safety threats, increase the amount of raw materials used in process complexity, and increase the production cost of tubular films, so as to improve production efficiency and product quality, The effect of saving raw materials and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof, but the claims of the present invention are not limited by embodiment.

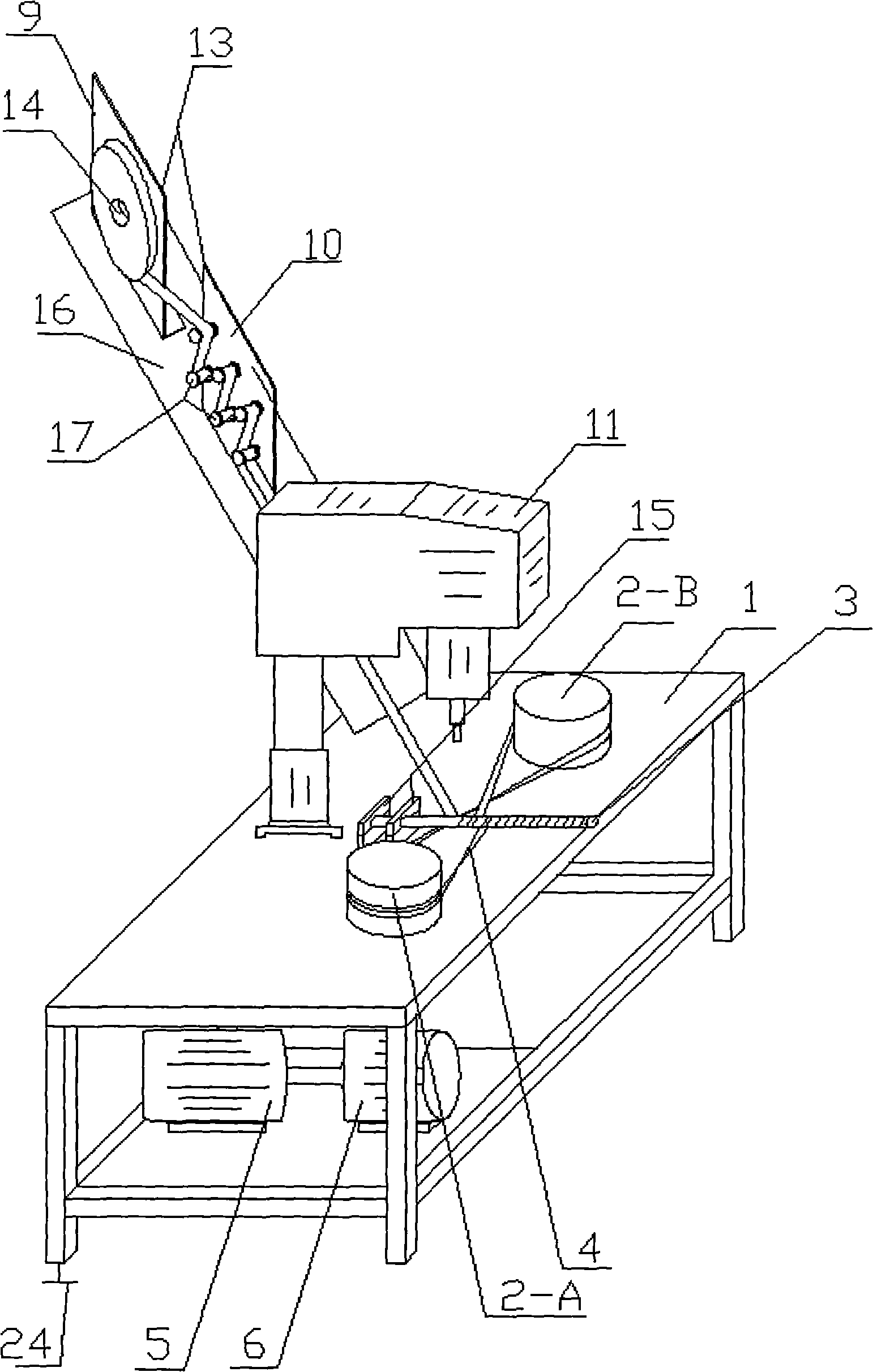

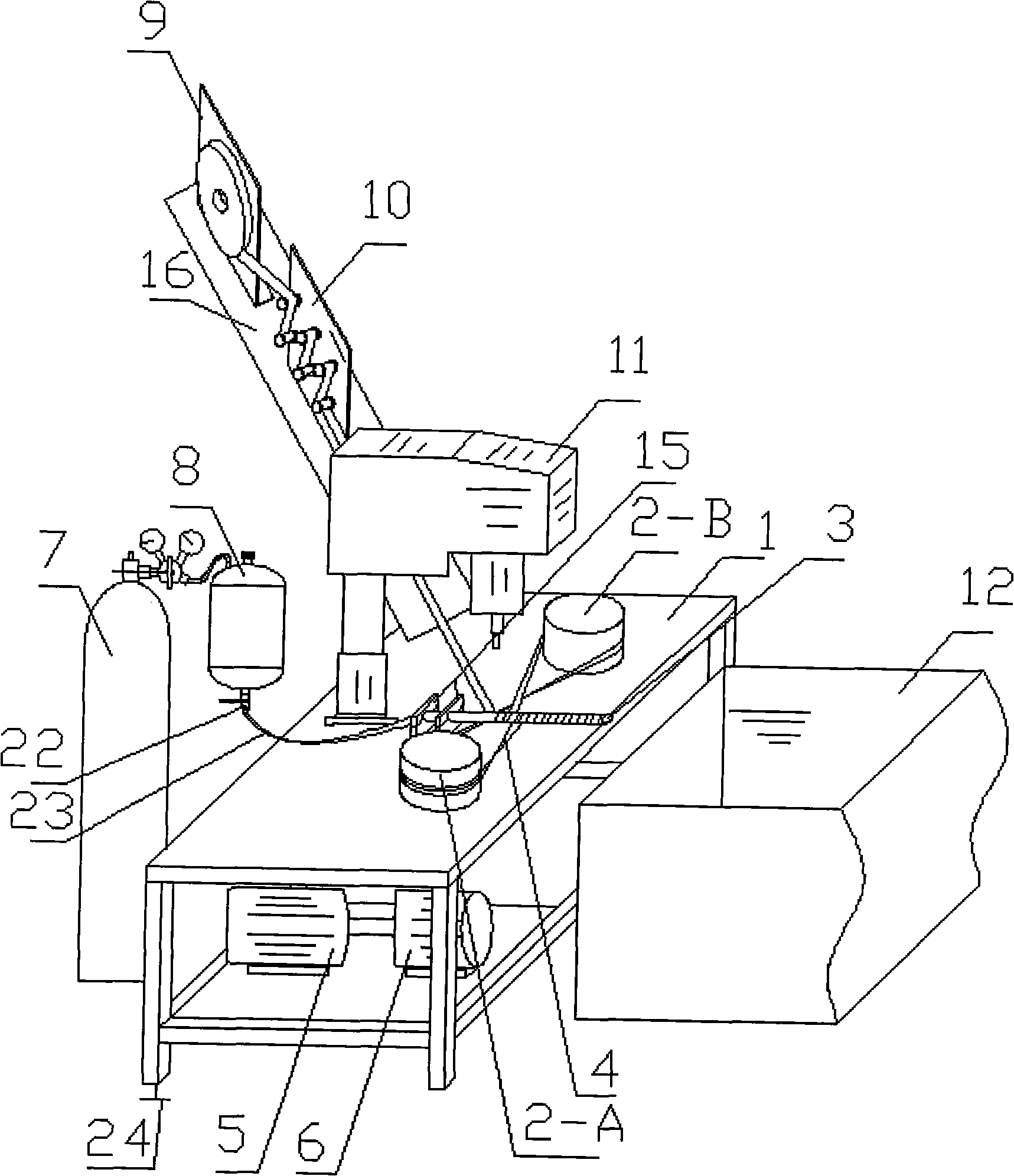

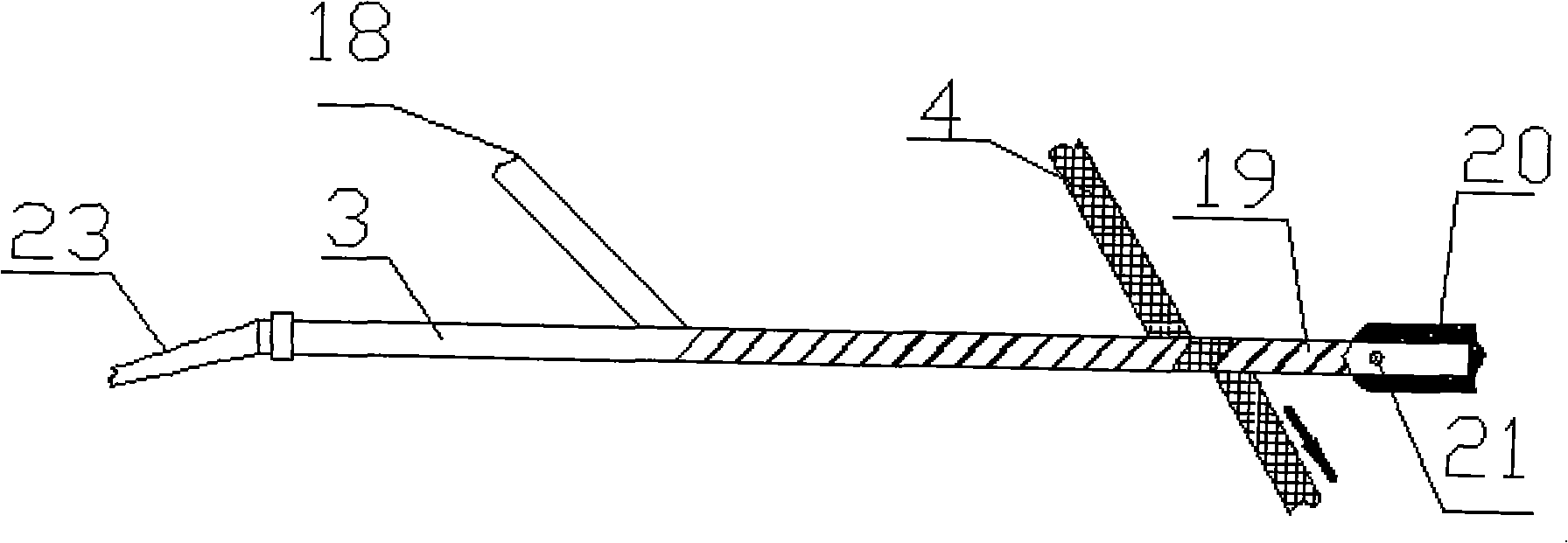

[0015] The coiler of the present invention's design (referring to figure 1 , 3 ), which is characterized in that it includes a double-layer frame 1, a coiling mechanism, a non-woven fabric feeding mechanism and an ultrasonic welding mechanism. The reducer 6, the reducer 6 is mechanically connected with a drive roller installed on the upper layer of the frame 1, that is, the main drive roller 2-A, and the main drive roller 2-A is connected with another drive roller installed on the upper layer of the frame 1 through the conveyor belt 4 That is, the auxiliary drive roller 2-B is connected, and a support rod 3 is arranged in the middle of the main drive roller 2-A and the auxiliary drive roller 2-B through a small bracket 15 fixed on the upper layer of the frame 1, and the conveyor belt 4 Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com