Pocket type adsorption desulfurization purifier

An adsorption desulfurization and purification device technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of easy scaling and corrosion of pipelines, low desulfurization efficiency, and difficulty in ensuring the efficiency of dust collectors, etc., to achieve effective purification Flue gas, the effect of improving the desulfurization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

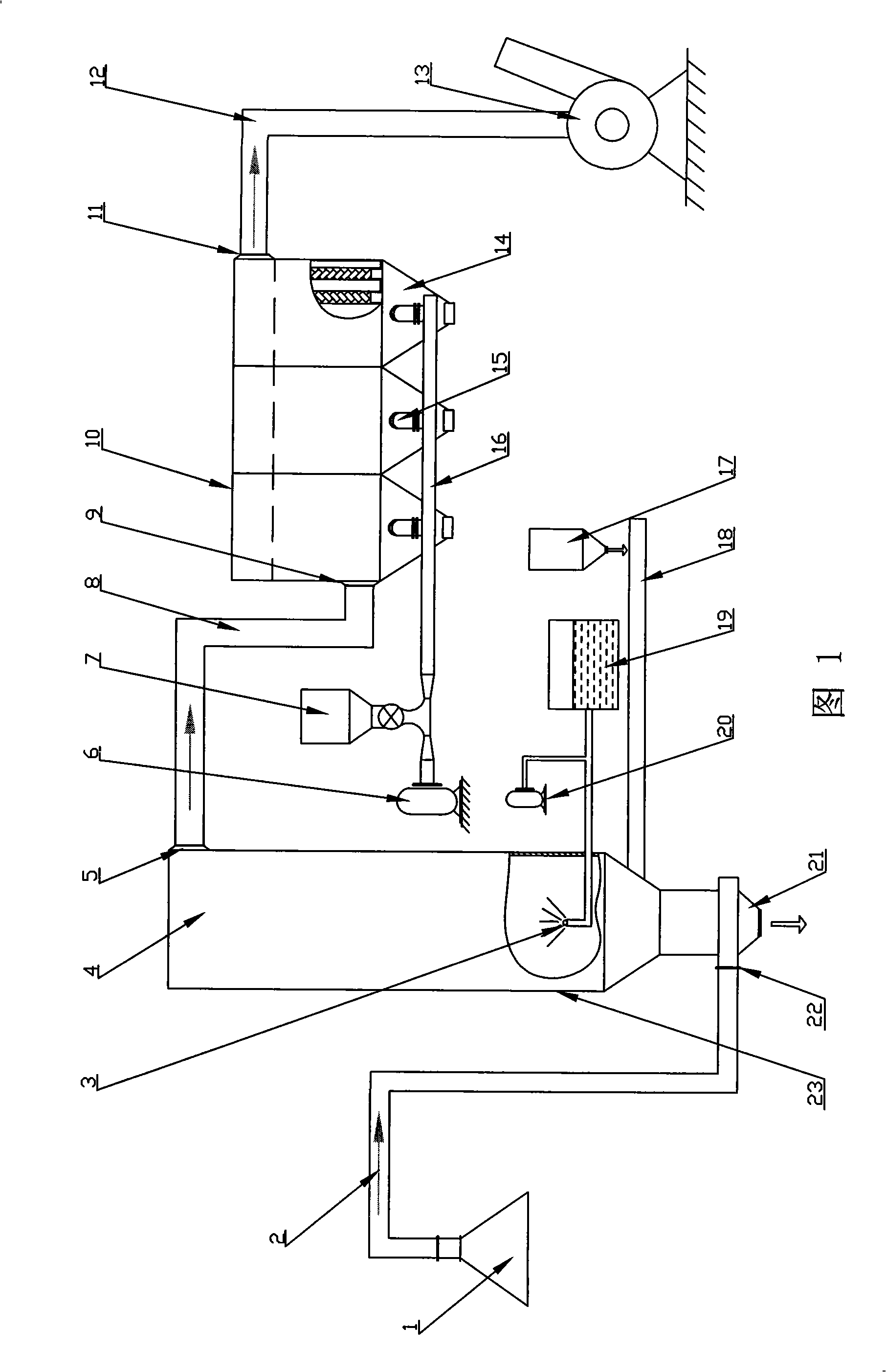

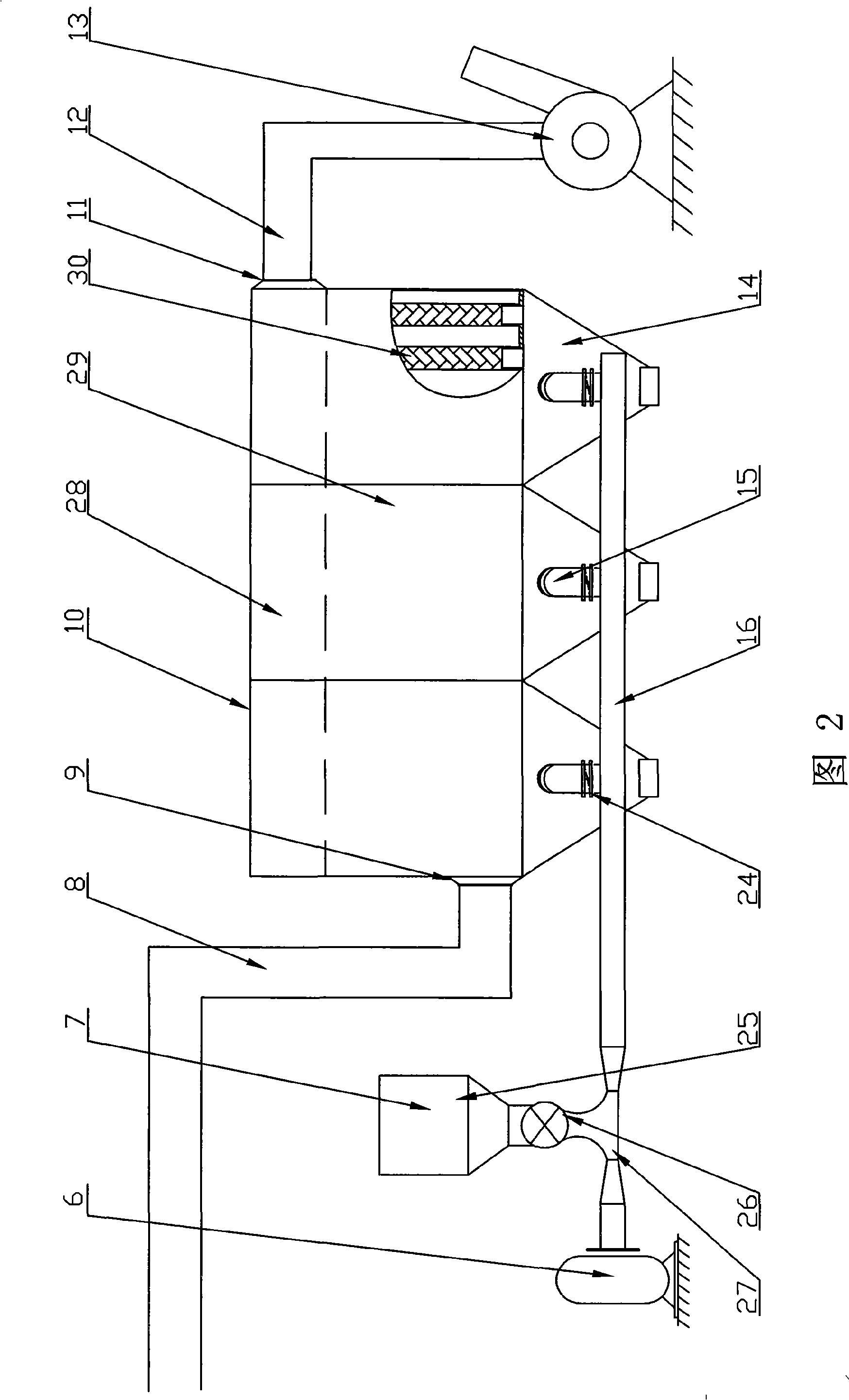

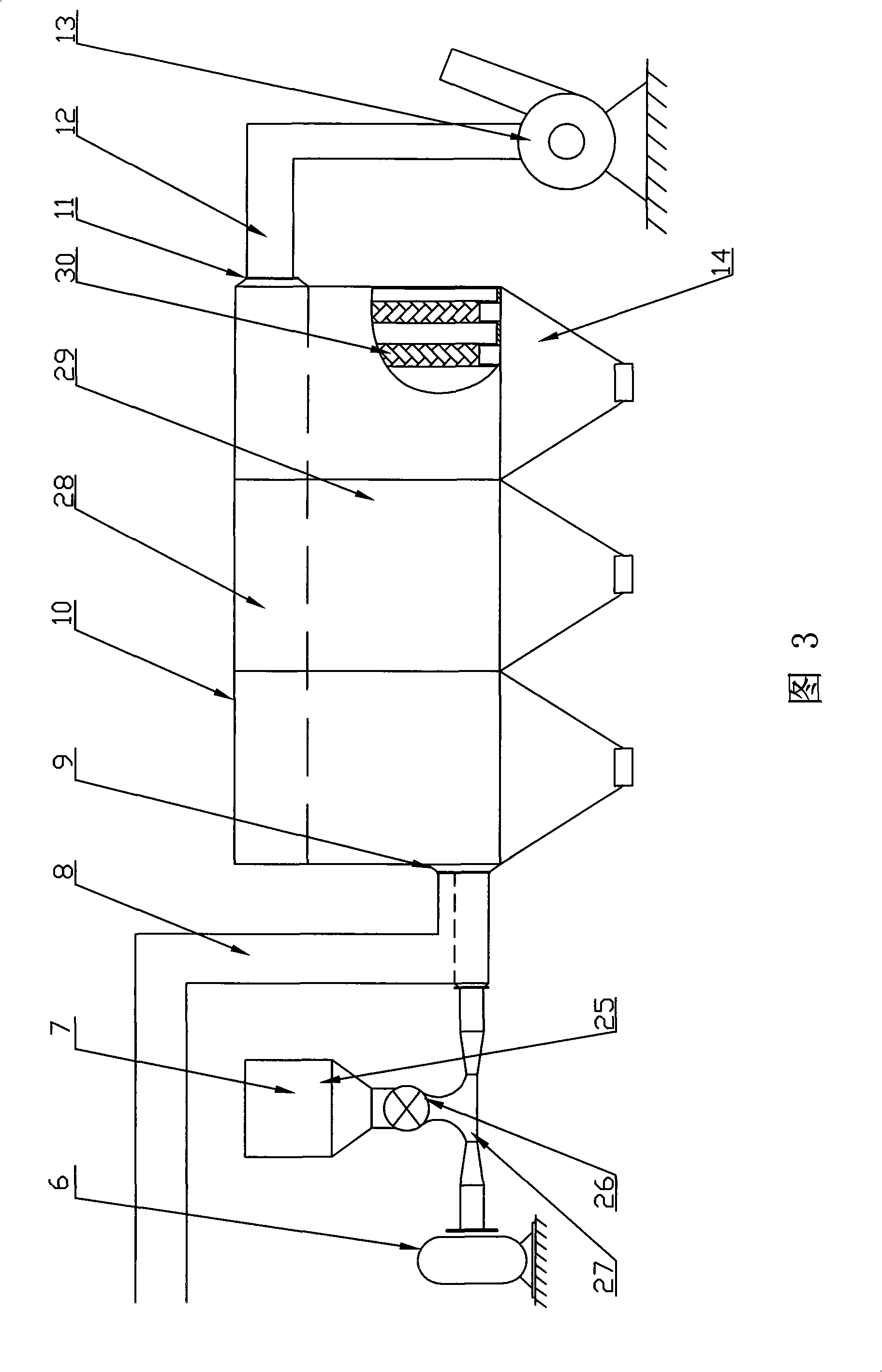

[0023] A bag-type adsorption desulfurization purification device, including a reaction tower device sequentially connected by a pipeline 8 and a pipeline 12, a bag filter 10, and a main fan 13, and the bag filter 10 is also connected with a desulfurizer automatic spraying device 7 .

[0024] The desulfurizing agent automatic spraying device 7 comprises a desulfurizing agent automatic spraying tank 25, a spraying pipe 16, a spraying connecting pipe 15, an automatic regulating valve 24, an automatic feeding machine 26, a pneumatic feeder 27, an airflow generator 6, and the desulfurizing agent is automatically sprayed. The spraying tank 25 is connected with the dust collector ash hopper 14 of the bag filter 10 through the spraying pipe 16 and the spraying connecting pipe 15, and the automatic feeding machine 26 of the desulfurizing agent automatic spraying tank 25 is installed at the lower part of the desulfurizing agent tank 25, and is connected with the air supply The feeder 27...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com