Optical products storing container

A technology for optical products and containers, which is applied in the field of optical product storage containers, can solve the problems that cannot be solved, the lateral sliding amount of the container body 101 becomes larger, and the practicality of the storage container disappears, so as to achieve the effect of preventing collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] Embodiments of the present invention will be described below with reference to the drawings.

[0070] First, the optical product storage container (hereinafter referred to as container) of the present invention will be described.

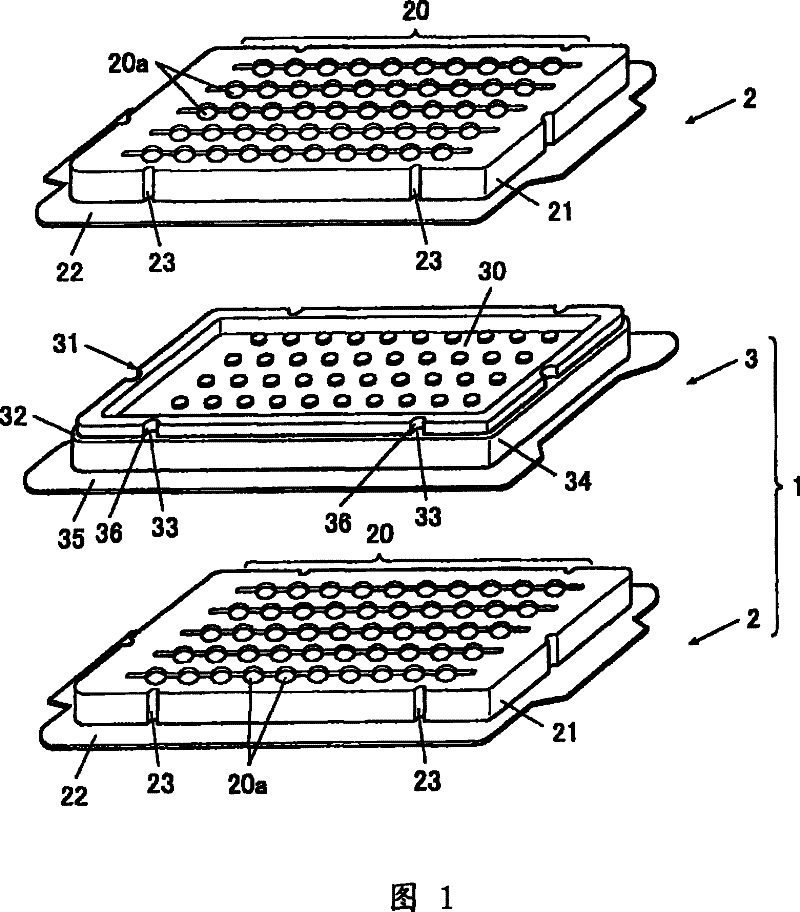

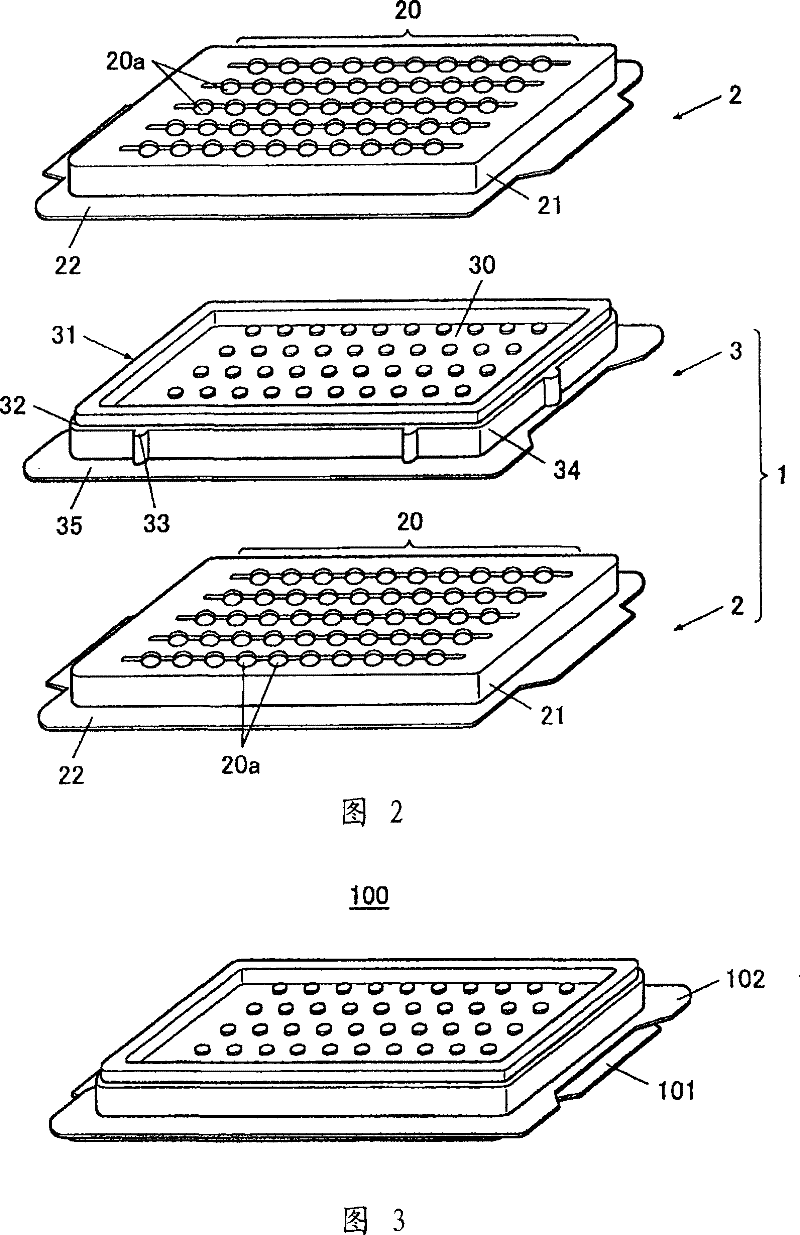

[0071] figure 1 It is an exploded perspective view of the container 1 of the first embodiment of the present invention.

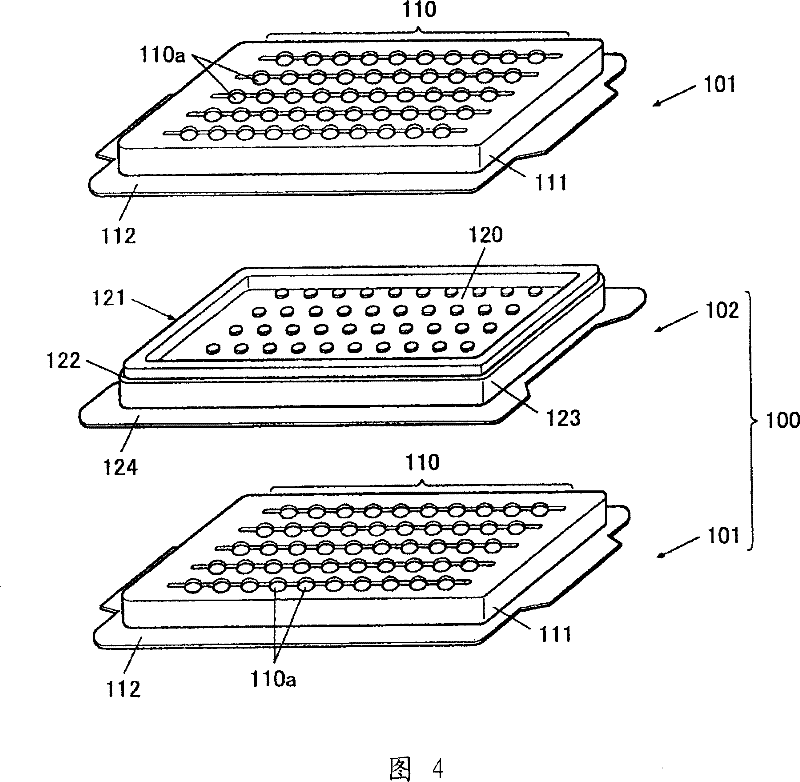

[0072] As shown in the figure, the container 1 accommodates optical products (not shown) and can be stacked in multiple layers, and includes a container body 2 and a lid member 3 that are substantially rectangular in plan view.

[0073] These container body 2 and lid member 3 are formed by vacuum forming a sheet-like resin material and have flexibility. The thickness of the sheet-like resin material in this embodiment is 0.3-0.5 mm.

[0074] Among these container main body 2 and cover member 3, the container main body 2 has the product placement part 20 in the center. The product placement part 20 has a plurality of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com