High pressure discharge lamp with discharge chamber

A technology of high-pressure discharge lamps and discharge tubes, which is applied in high-pressure discharge lamps, discharge lamps, gas discharge lamps, etc., can solve the problems of shortened lifespan, and achieve the effect of optimizing the electrode geometry and effectively coupling the heating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The principle circuit of an electronic ballast for high-pressure discharge lamps is based eg on page 217 of Sturm Figure 4 .44 implementation form.

[0021] The working method can use bipolar rectangular wave supply current. Such a supply current is characterized, for example, by a short-term residual power for stable rectification. The power obtained therein corresponds to the rated power of the lamp and is lower than the rated power in the dimmed situation.

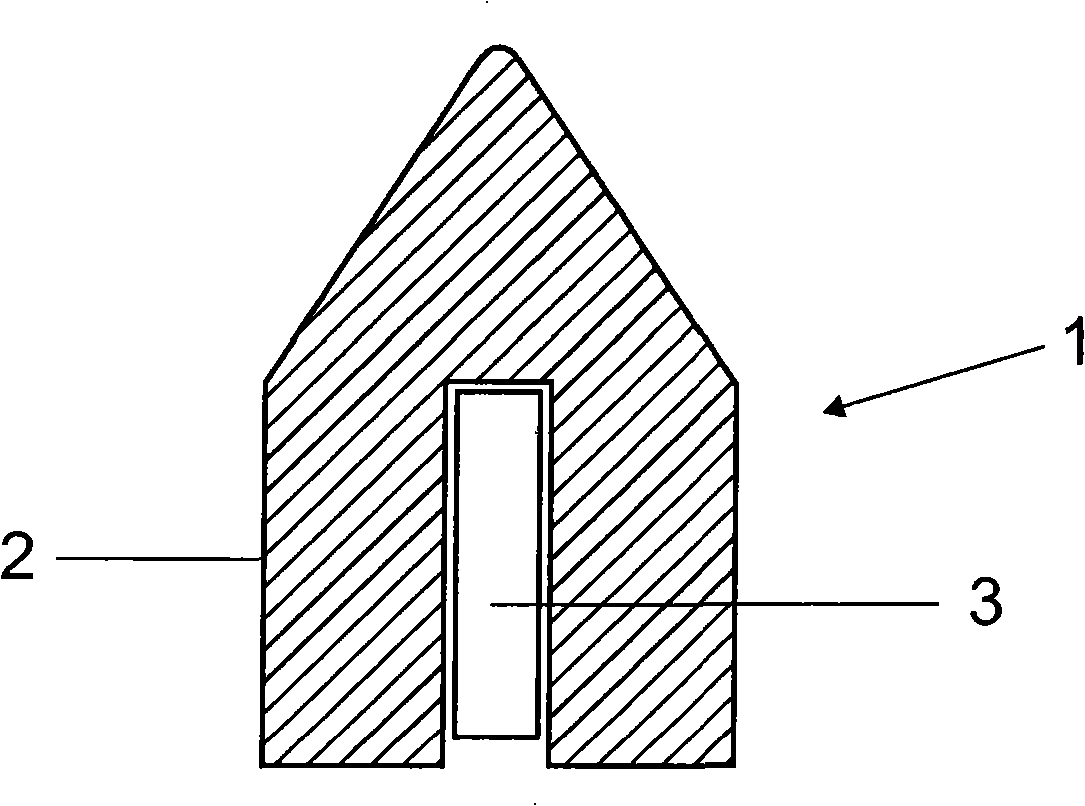

[0022] figure 1 A suitable electrode 1 for a metal halide lamp is shown in , where heating is effected by a heating core 3 placed in the head 2 of the electrode. In this case, the contacts of the heater of the core can be connected to the electrodes.

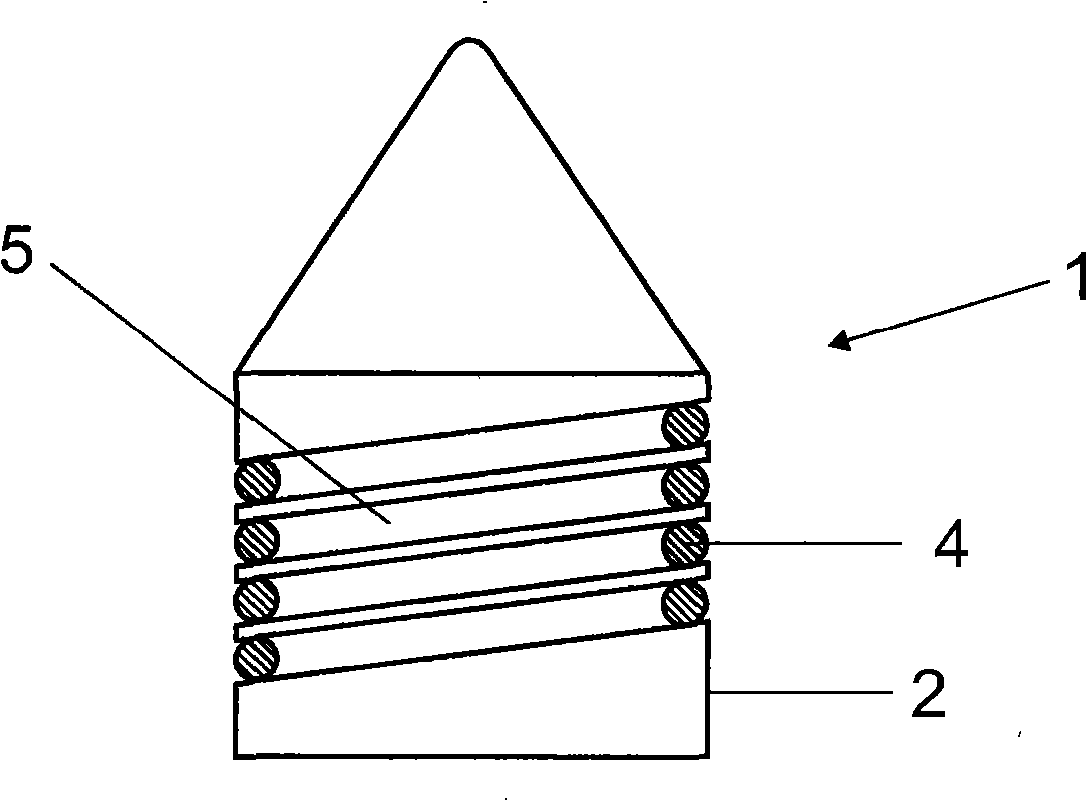

[0023] figure 2 The head 2 of the electrode 1 is shown in , wherein the heating means in the form of a wire 4 is embedded in a thread-like groove 5 of the head 2 . The contacts can still be connected to the electrodes.

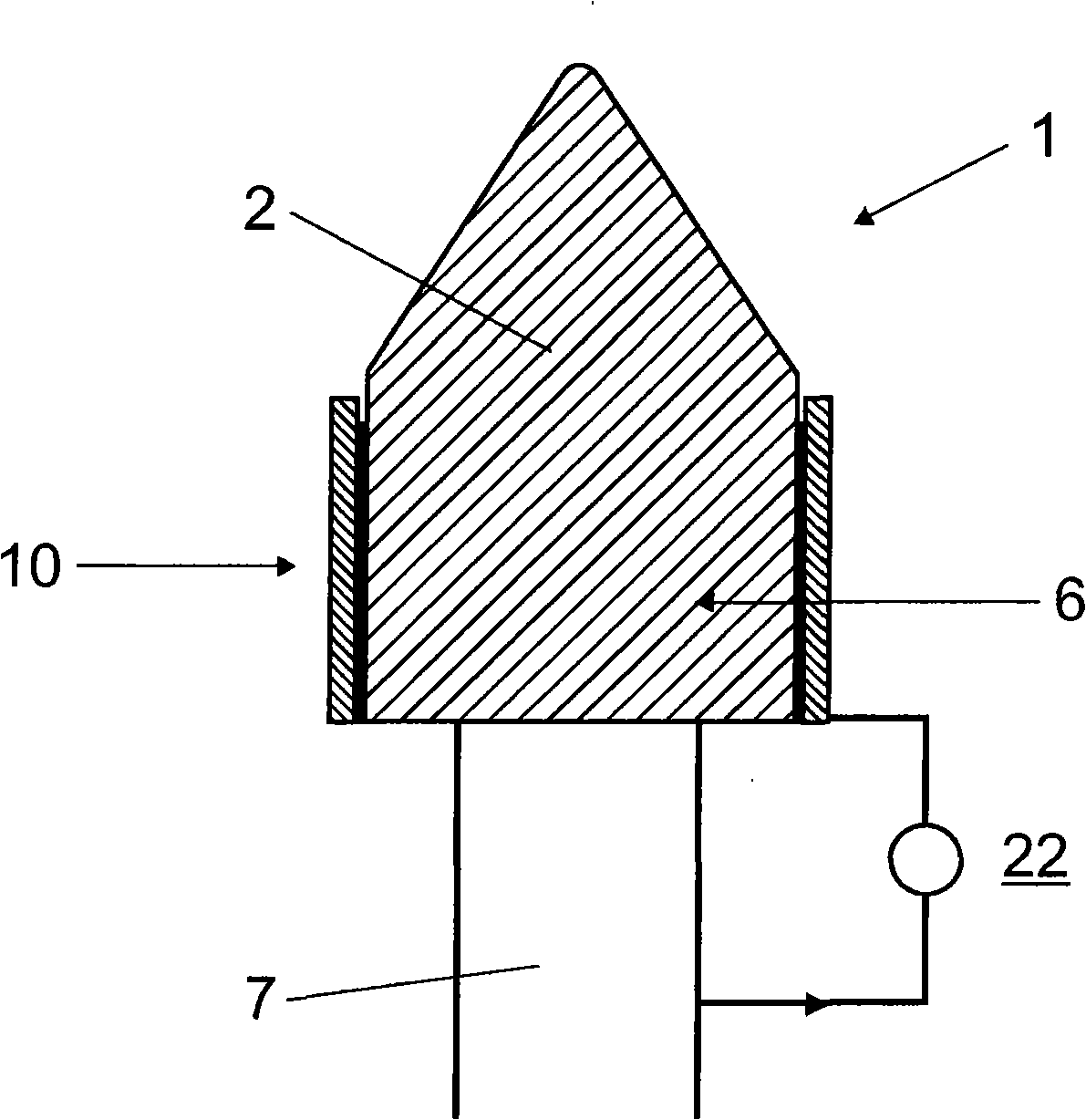

[0024] exist image 3 In , the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com