Multi-lens measurement method

A measurement method and multi-lens technology, applied in the field of measurement, to achieve high measurement accuracy, improve measurement speed and efficiency, and eliminate mechanical errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

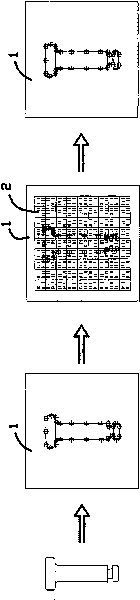

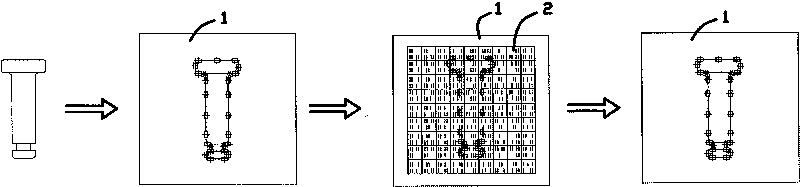

[0025] Such as figure 1 As shown in the figure, to measure the plane parameters of the "T"-shaped workpiece shown in the figure, the first thing is to take out a sample workpiece (one sample workpiece can be taken out of all workpieces), and the sample workpiece is placed on the measurement platform 1, and multiple measurement lenses Align the distribution of different measurement parts of the measured object (model workpiece), fix each measurement lens after adjustment; then remove the sample workpiece, and insert a grid coordinate plate 2 on the measurement platform 1, according to the grid coordinate plate 2 Construct a reference coordinate system. At this time, the focal points of multiple measuring lenses respectively establish a coordinate in the coordinate system, which is recorded as a reference point and stored in the microcomputer; the reference point is a reference point, which is used to convert and measure other The actual coordinates of the measured object; the m...

Embodiment 2

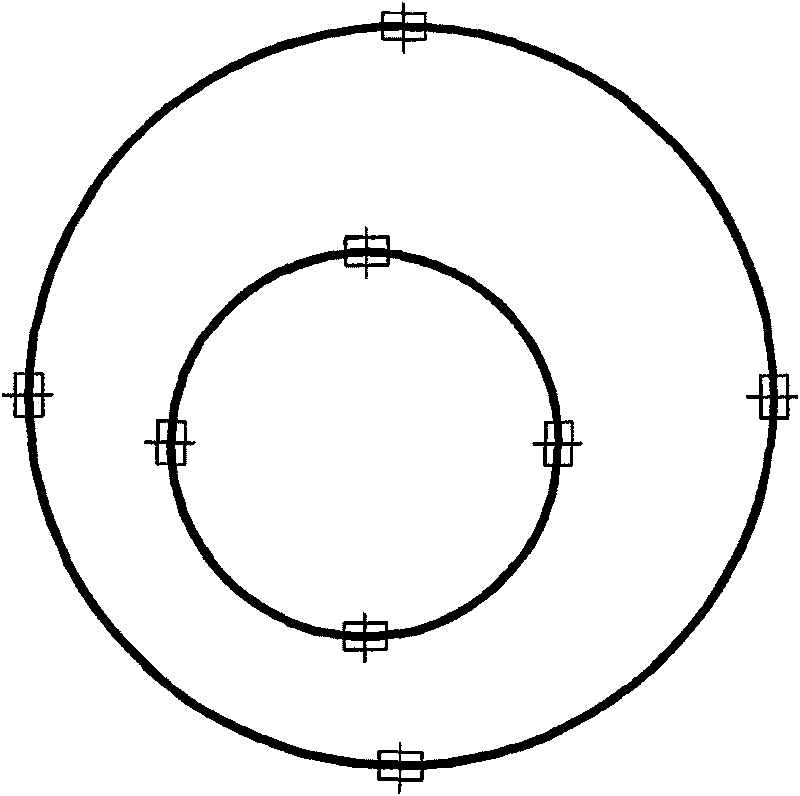

[0028] Such as figure 2 As shown, when measuring the concentricity, multiple measurement arrays are distributed on the inner and outer circumferences to measure simultaneously, and the actual inner and outer circumferences can be determined according to the actual coordinate parameters, so that the concentricity of the inner and outer circles can be further determined.

[0029] Of course, the scope of application of the present invention is not limited to the above-mentioned embodiments, and it can also be used for measurement of irregular lines, surfaces, angles or radians, and also for stereo measurement. For stereo measurement, the lens can be erected or placed horizontally Or set it obliquely, so as to obtain a three-dimensional distribution and meet the measurement requirements. The present invention provides a measurement concept, which is different from single-lens measurement, obtains a better measurement method, and promotes the development of measurement technology....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com