Petrol engine intake duct

A gasoline engine, intake port technology, applied in engine components, machines/engines, cylinders, etc., can solve problems such as unreachable, and achieve the effect of reducing flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

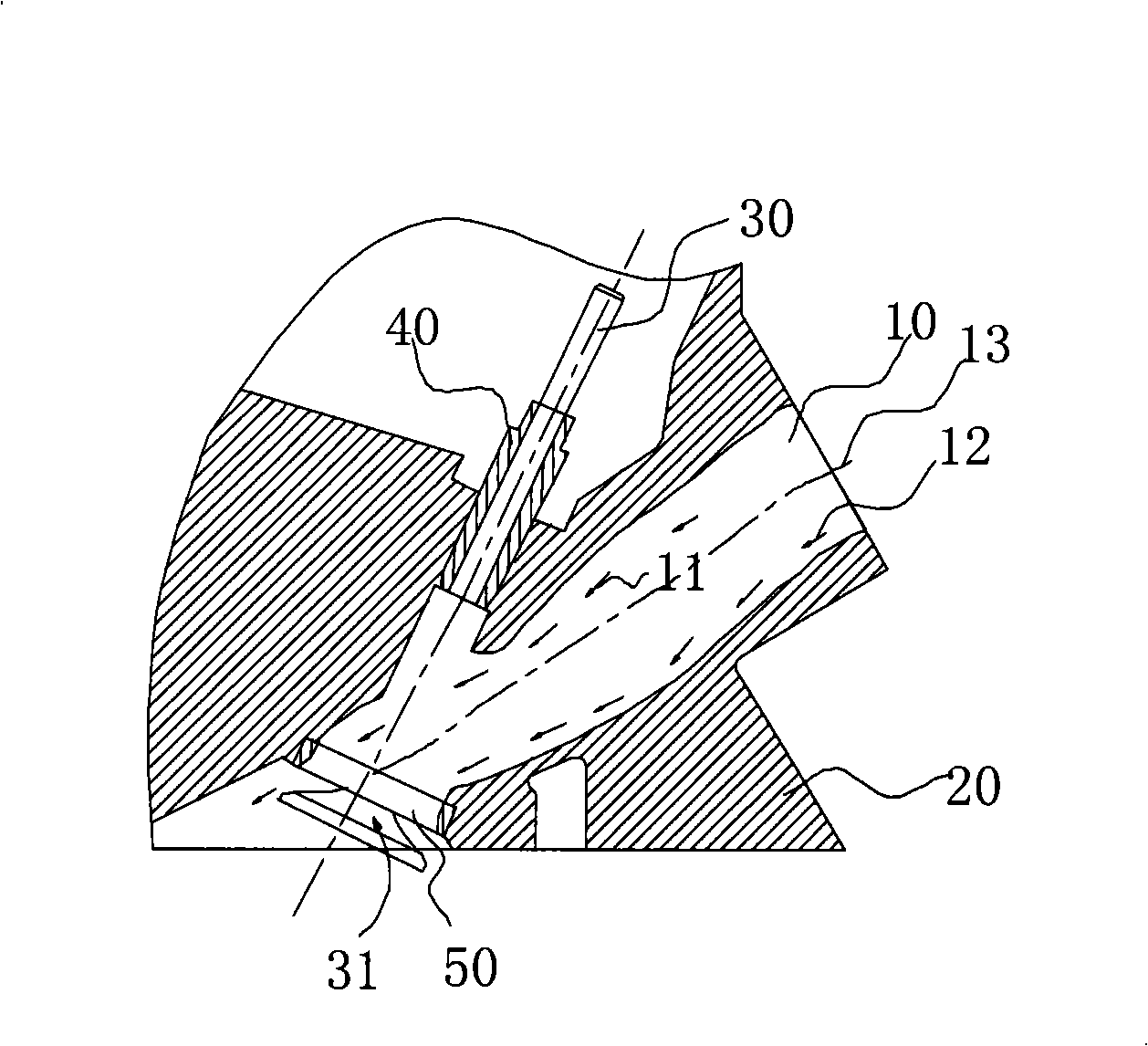

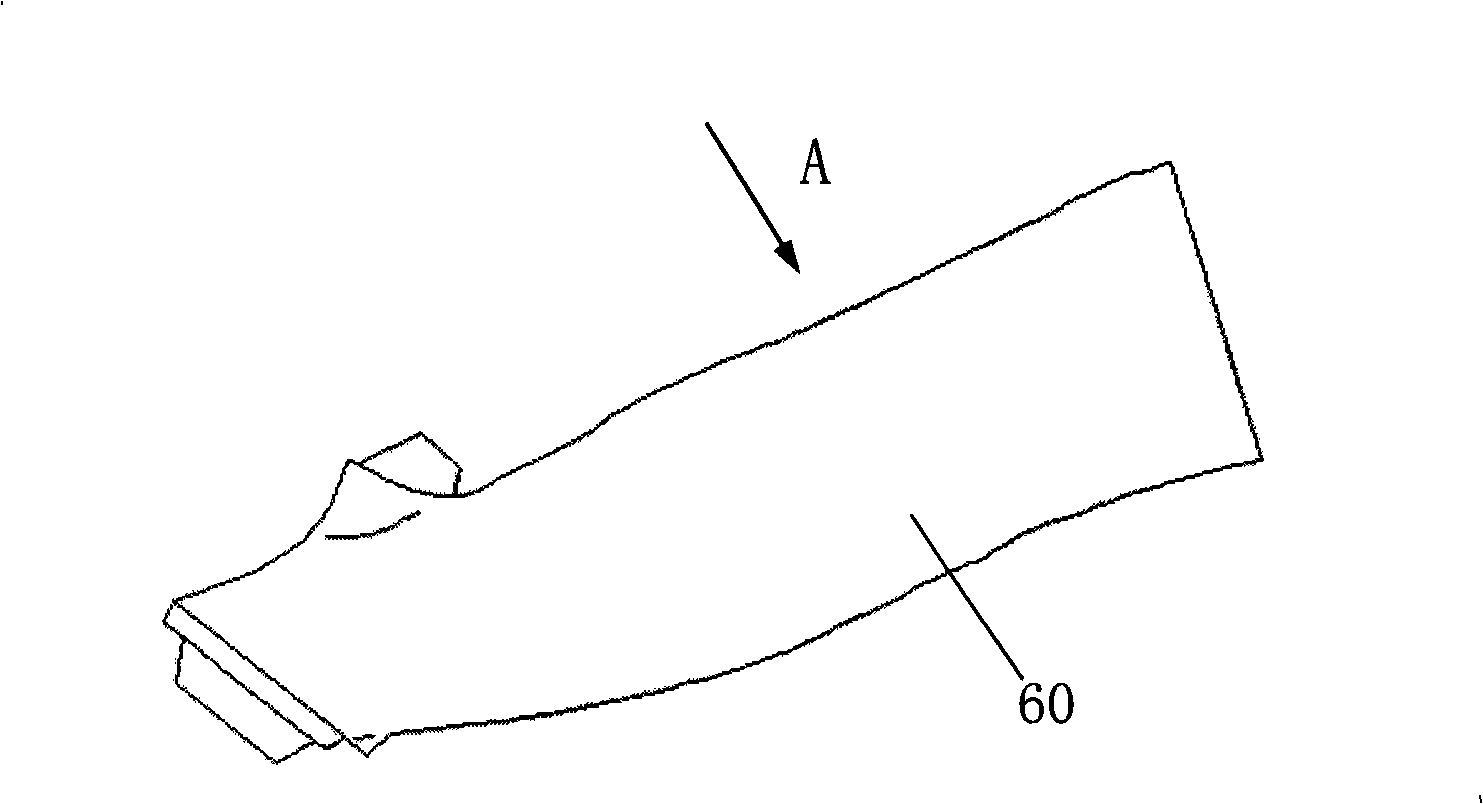

[0012] Such as figure 1 As shown, the intake port 10 on the gasoline engine cylinder head 20 is straight and extends obliquely to the valve. The valve 30 is arranged to move in the valve guide 40 . The apertures of the inlet section of the air inlet passage 10 are approximately the same, and the air outlet section is closed in a gentle shape. The included angle between the centerline of the air inlet passage 10 and the centerline of the valve stem provided above is 8~ 45°, the preferred included angle is 8-30°, the best included angle is 8-15°, and the angle of the embodiment given in the accompanying drawings is 12°. The setting of the above-mentioned angles actually needs to match the angle and radian of the valve stem’s cone surface. A small angle can ensure a compact arrangement of the air passage and the cylinder head, which can effectively reduce the overall weight of the engine and save layout space.

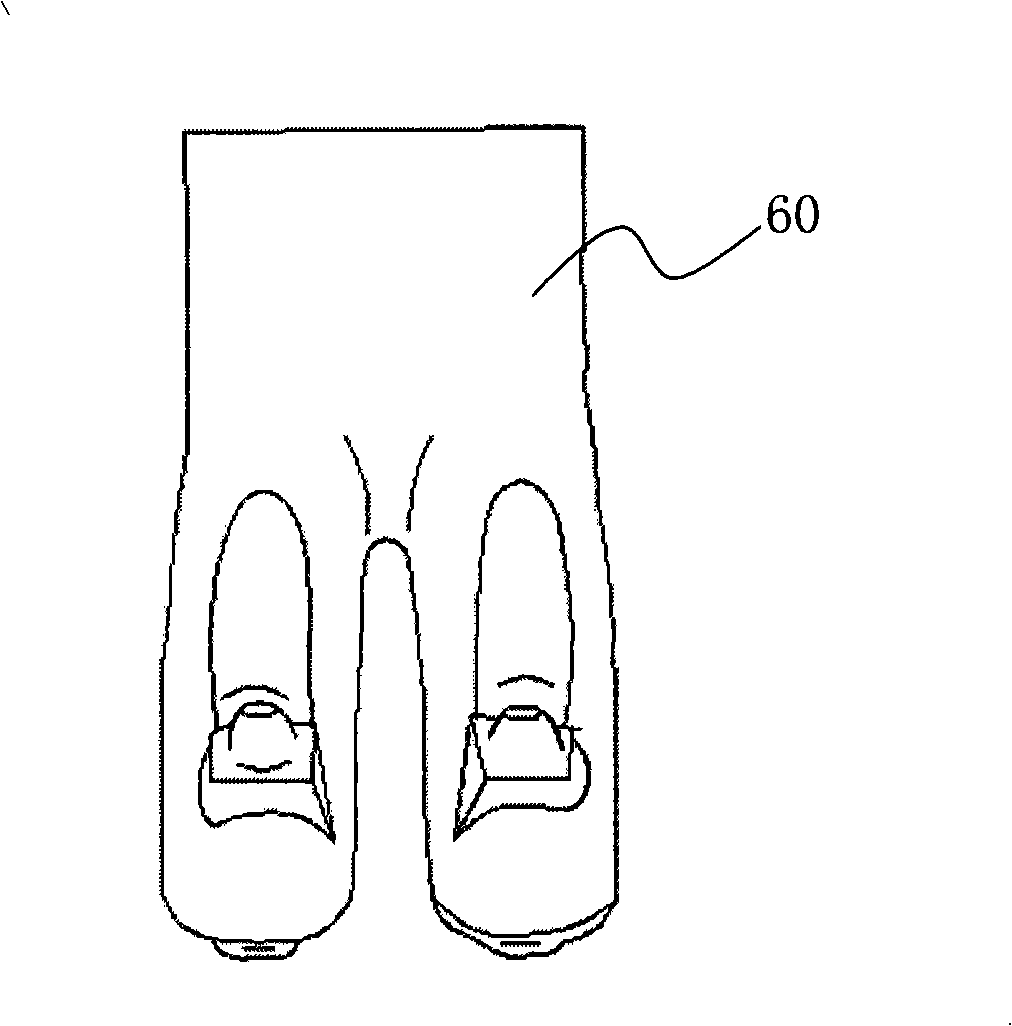

[0013] exist figure 1 , 4 , 5, it can be seen that the upper airf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com