Method and device for treating high concentration nitrogen waste water by using microorganism

A microbial treatment, high-concentration nitrogen technology, applied in biological water/sewage treatment, oil/oil/float removal devices, separation methods, etc., can solve the problem of low efficiency, inconvenient management and operation control, and poor ammonia nitrogen removal question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

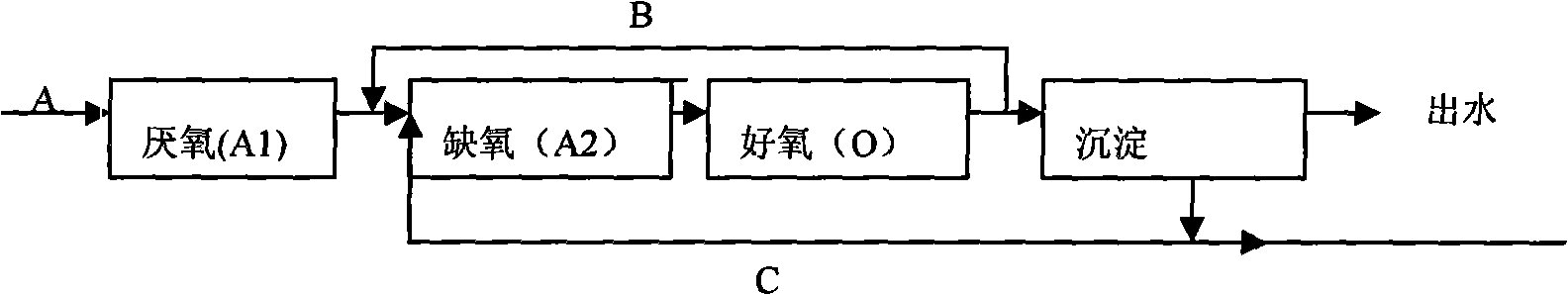

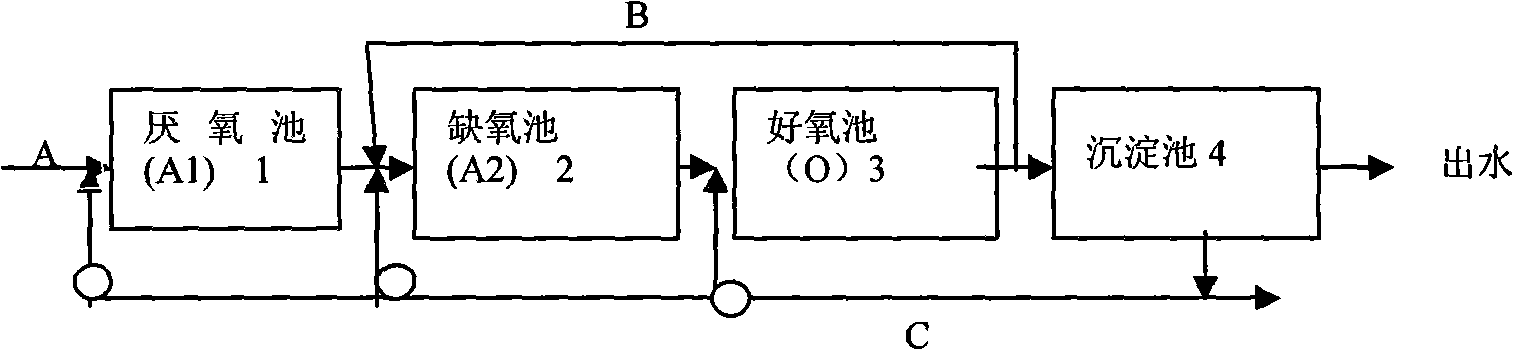

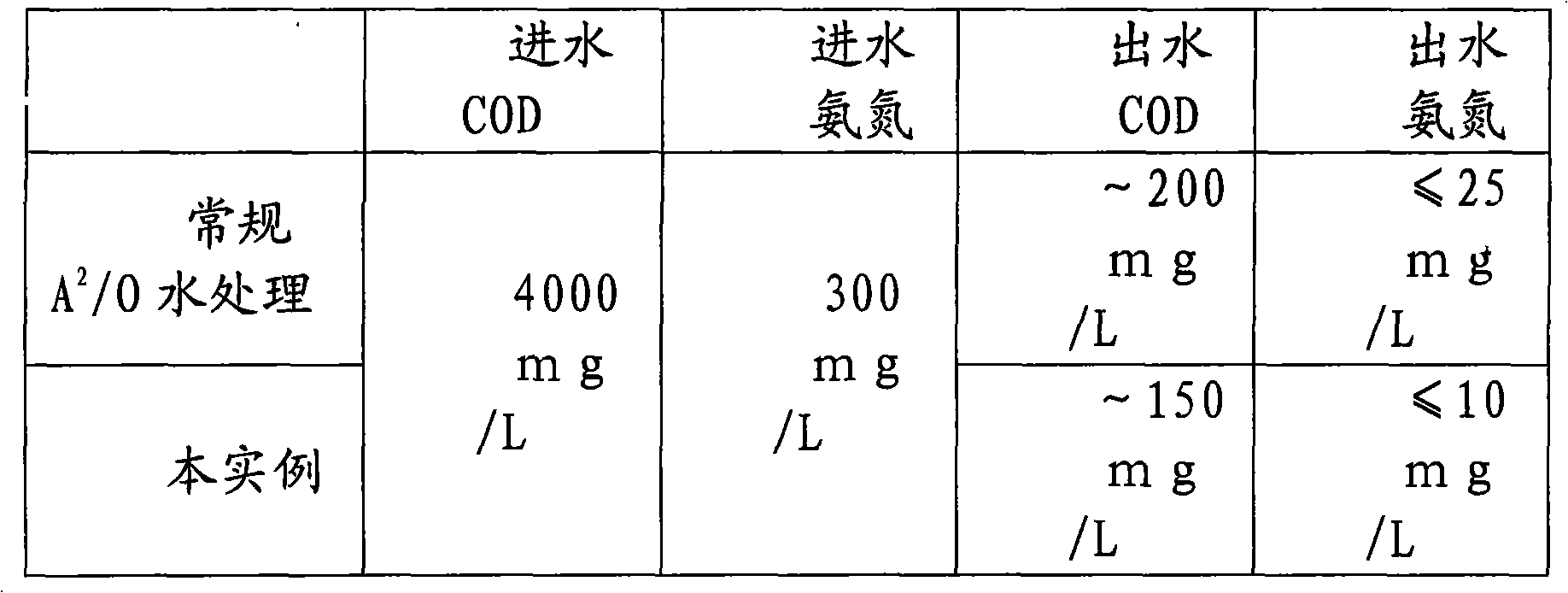

[0132] Such as figure 2 As shown, the anaerobic pool 1, the anaerobic pool 2, the aerobic pool 3 and the sedimentation tank 4 constitute four main units in space. The sludge return pipeline leads to the anaerobic pool 1, the facultative pool 2 and the aerobic pool 3; the anaerobic pool 1, the facultative pool 2 and the aerobic pool 3 are respectively provided with independent switches for controlling the sludge return ratio.

[0133] The wastewater entering the system first passes through the air flotation tank for pretreatment to remove oil and suspended solids (and slag). Then the waste water enters the anaerobic pool 1, and the waste water and the anaerobic bacteria mass in the pool undergo biochemical reactions without oxygen supply, degrade some harmful substances in the sewage, and improve the biodegradability of the sewage at the same time, creating conditions for the next stage of treatment. In order to meet the needs of biochemical reactions in anaerobic and anoxic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com