Highly effective ink-jet decorating machine

An inkjet printing machine, high-efficiency technology, applied in printing, typewriters, etc., can solve the problems of high-speed and high-precision textile inkjet printing and low work efficiency, and achieve simple processing and control principles, simple control units, and printing make better effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

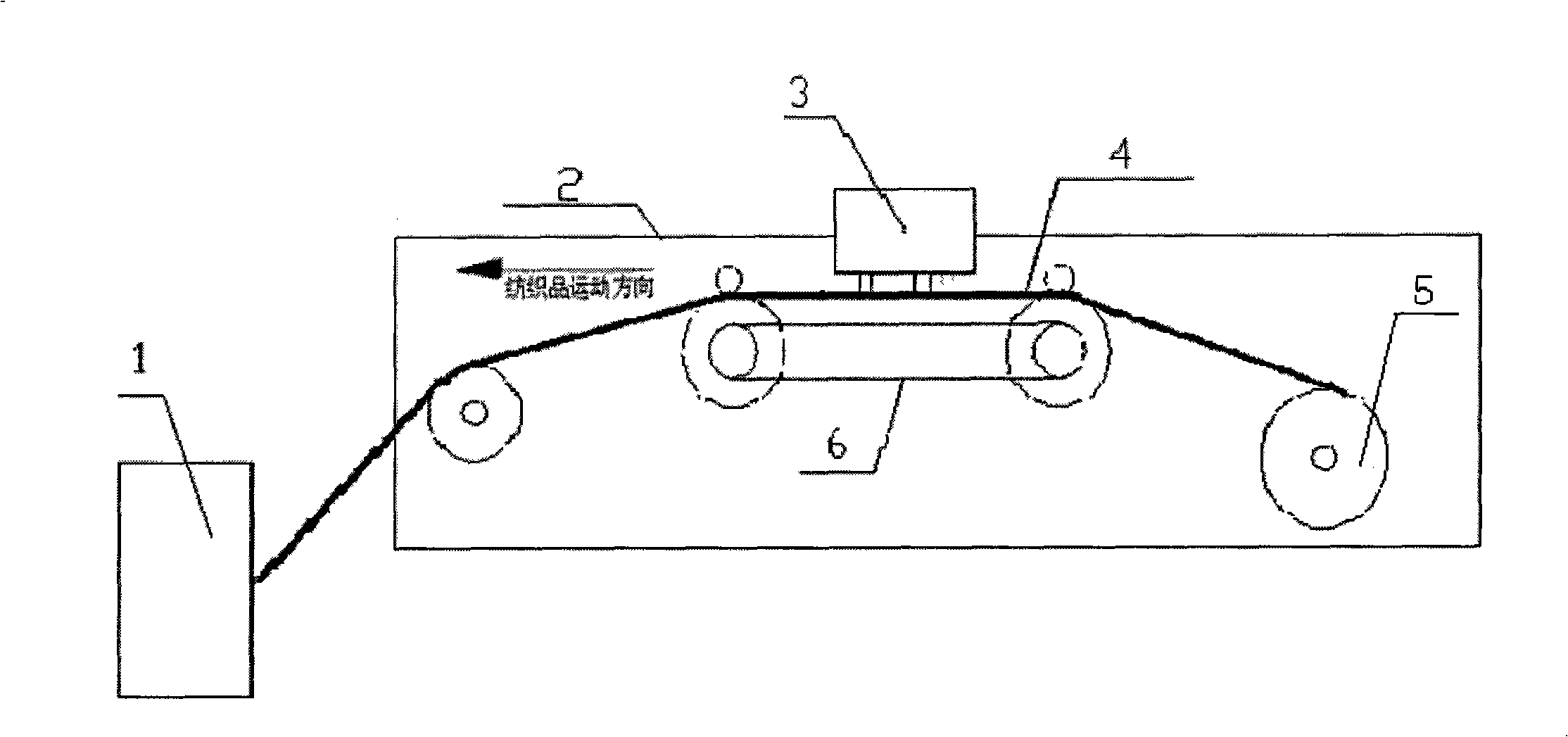

[0034] Such as Figure 1-7 As shown, the inkjet printing method of the present invention is composed of a carrier driving system 6 , a frame 2 , an inkjet system 3 , a textile post-processing system 1 , a textile 4 and a fabric winding roller 5 . Its characteristic is that the inkjet system 3 can be fixedly installed on the frame 2 without moving, and the textile 4 advances at a relatively high speed under the drive of the prop driving system 6, and the inkjet system 3 is driven by the control unit to press correspondingly. Ink needs to be sprayed onto the textile 4 to complete the printing.

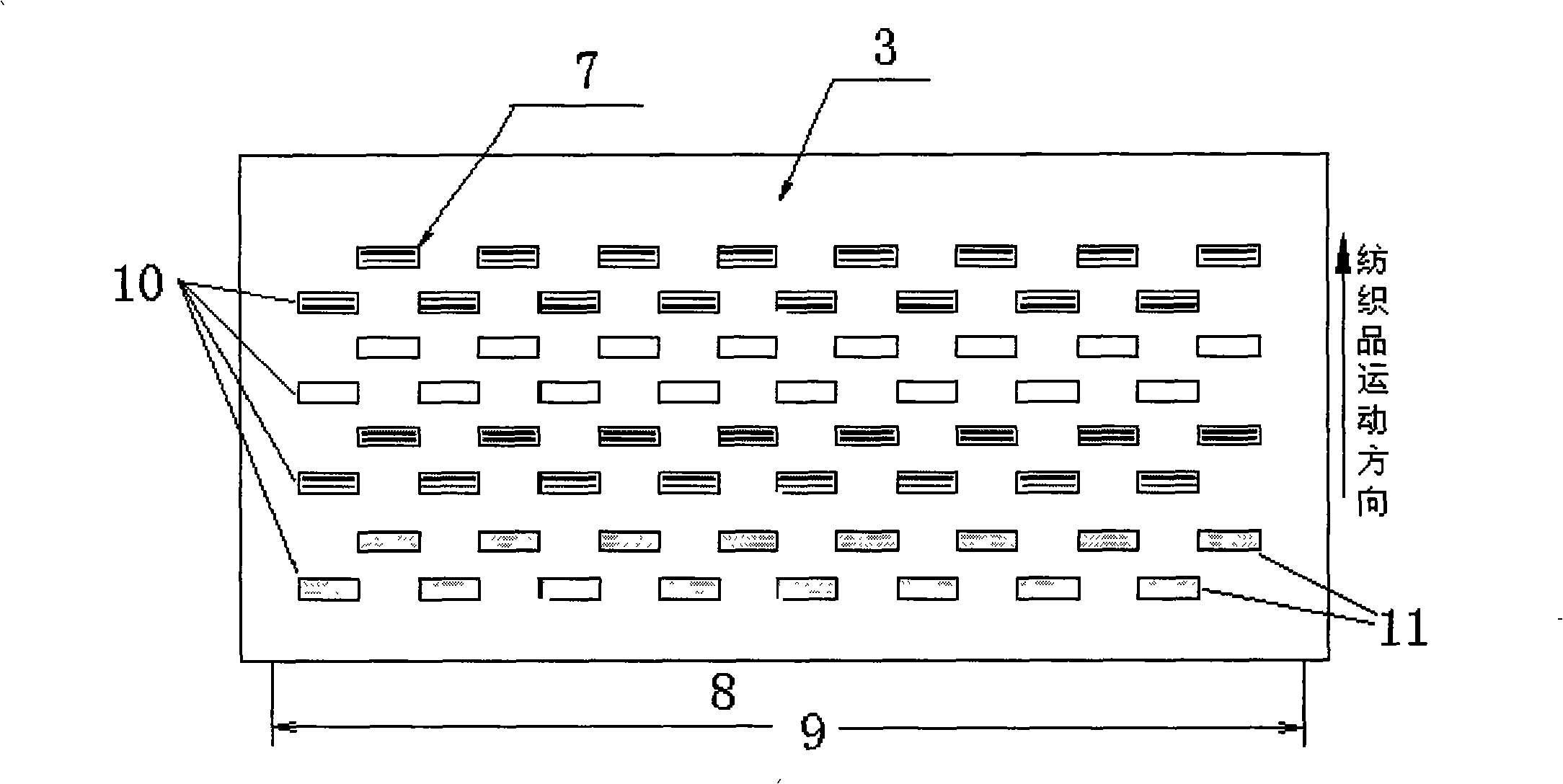

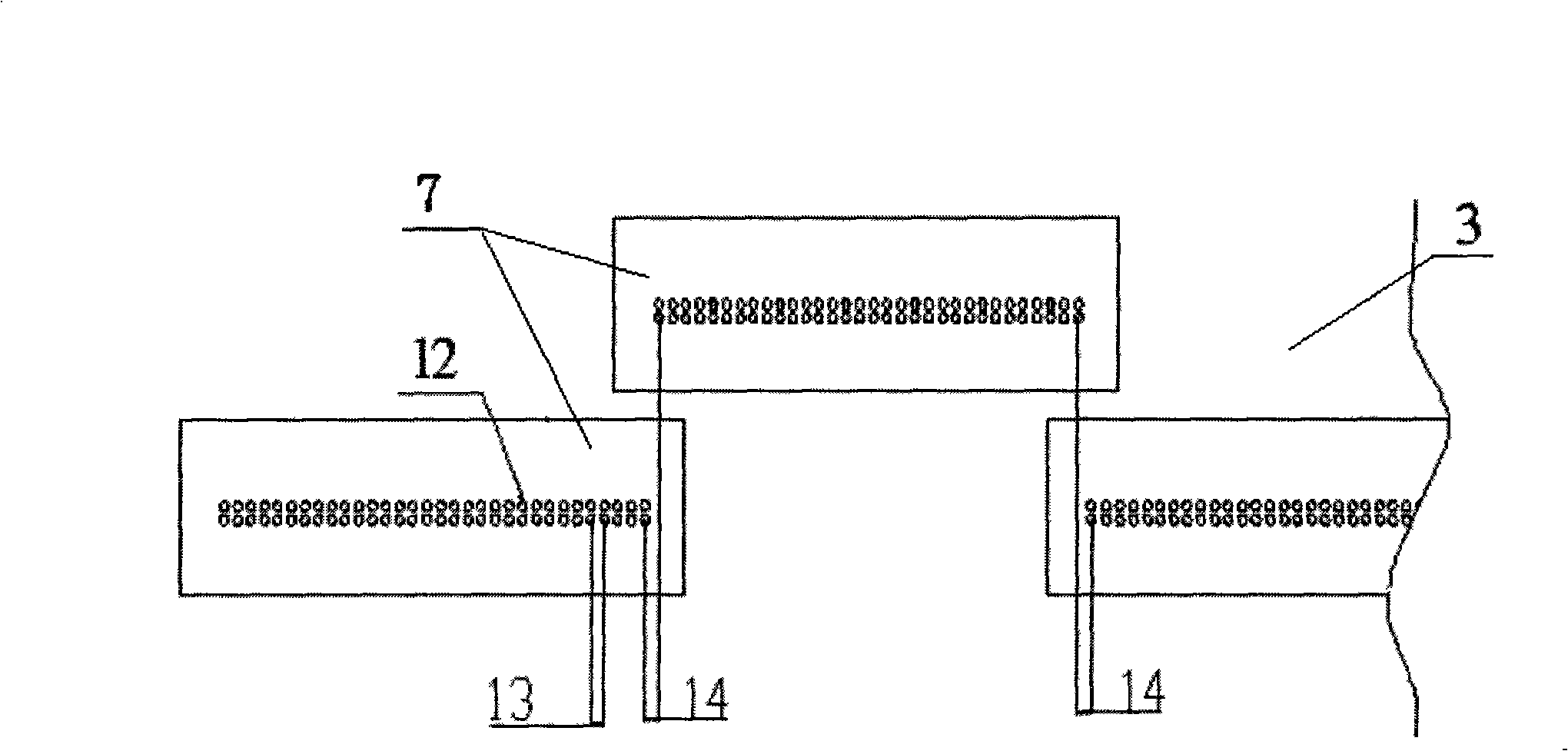

[0035] The inkjet system 3 of the patent of the present invention can be slightly moved laterally during the inkjet printing process. The inkjet system is composed of several identical inkjet units 15, each inkjet unit 15 is controlled by the same pattern 16 signal, and prints out at the same time. The same patterns, these patterns have looping features 20 in the transverse direction. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com