Equipment for dissembling waste and old circuit board

A technology for waste circuit boards and equipment, applied in welding equipment, metal processing equipment, metal processing and other directions, can solve problems such as low manual operation efficiency, decomposition of PCB board paint, and inability to recycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described below according to accompanying drawing.

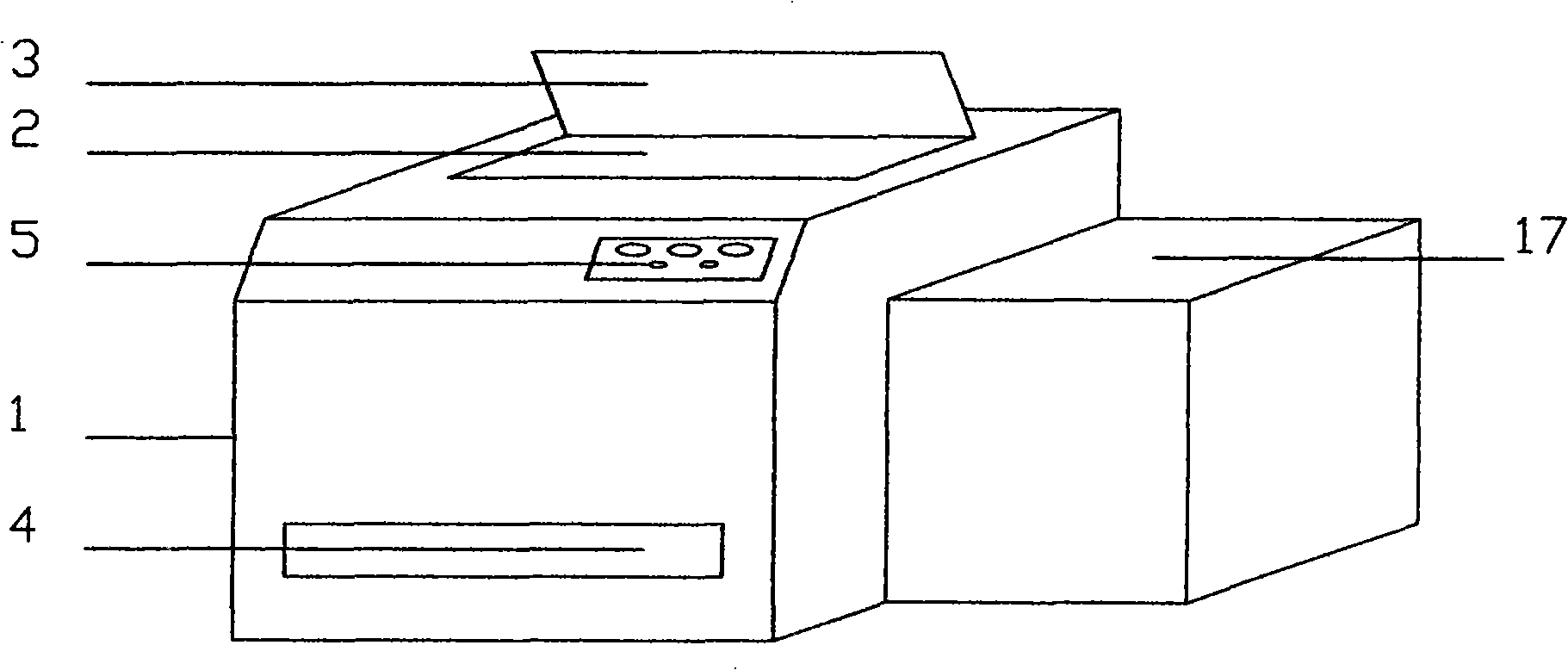

[0014] figure 1 Among them, 1 is the shell of the equipment. The shell is composed of two layers of steel plates with heat insulation materials such as glass fiber cotton in the middle. The top plate of the shell 1 is provided with a feeding port 2 for delivering waste circuit boards. The feed opening cover 3 that can be opened and closed is opened during work and the feed opening cover 3 is fed into the inside through the feed opening 2. The lower part of the casing 1 is provided with a discharge port 4, and the components disassembled during work and the empty circuit board after the components are disassembled will fall out of the discharge port 4, and the upper edge of the discharge port 4 can also be installed with a soft durable The hot silicone sheet hangs down to block the discharge port 4, which will not affect the falling of the components and parts and can block the hot air in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com