Sewage treatment device

A technology of sewage treatment device and power device, which is applied in the direction of water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc. It can solve problems such as inadaptability, uneven delivery, limited delivery area, etc., and achieve The structure is simple, convenient for later maintenance and handling, and the effect of improving the area covered by spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

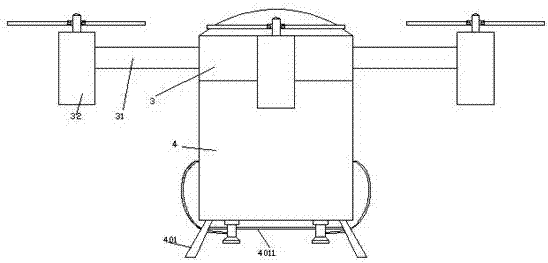

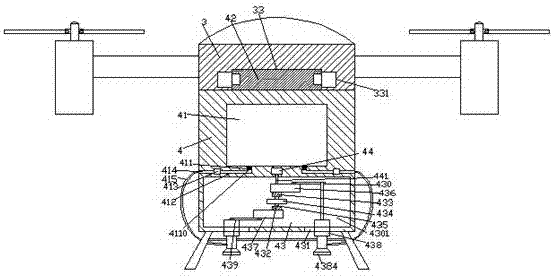

[0023] Such as Figure 1-Figure 5 As shown, a sewage treatment device of the present invention includes a main body 3 and an operating main body 4 arranged at the bottom of the main body 3. The operating main body 4 is provided with an alum chamber 41, and the inner bottom wall of the alum chamber 41 is provided There is a power device 44. The operating body 4 below the alum chamber 41 is provided with a transmission cavity 43. The left and right sides of the inner bottom wall of the transmission cavity 43 are correspondingly provided with guide grooves 431. Each guide groove A guide block 438 is provided in the 431, and a first plate 433 and a second plate 432 are arranged correspondingly up and down in the transfer cavity 43, and the first plate 433 and the second plate 432 are on both front and back sides. In an elongated configuration, between the first plate 433 and the second plate 432 is provided a rotating shaft 435 extending vertically, and the top extension of the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com