Large-aperture pressure relief drilling machine

It is a large-aperture drilling rig technology, which is applied in the direction of drill pipes, drill pipes, drilling equipment, etc. It can solve the problems of inconvenient installation and removal of drill pipes, achieve the effects of saving manpower, realizing automatic disassembly, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

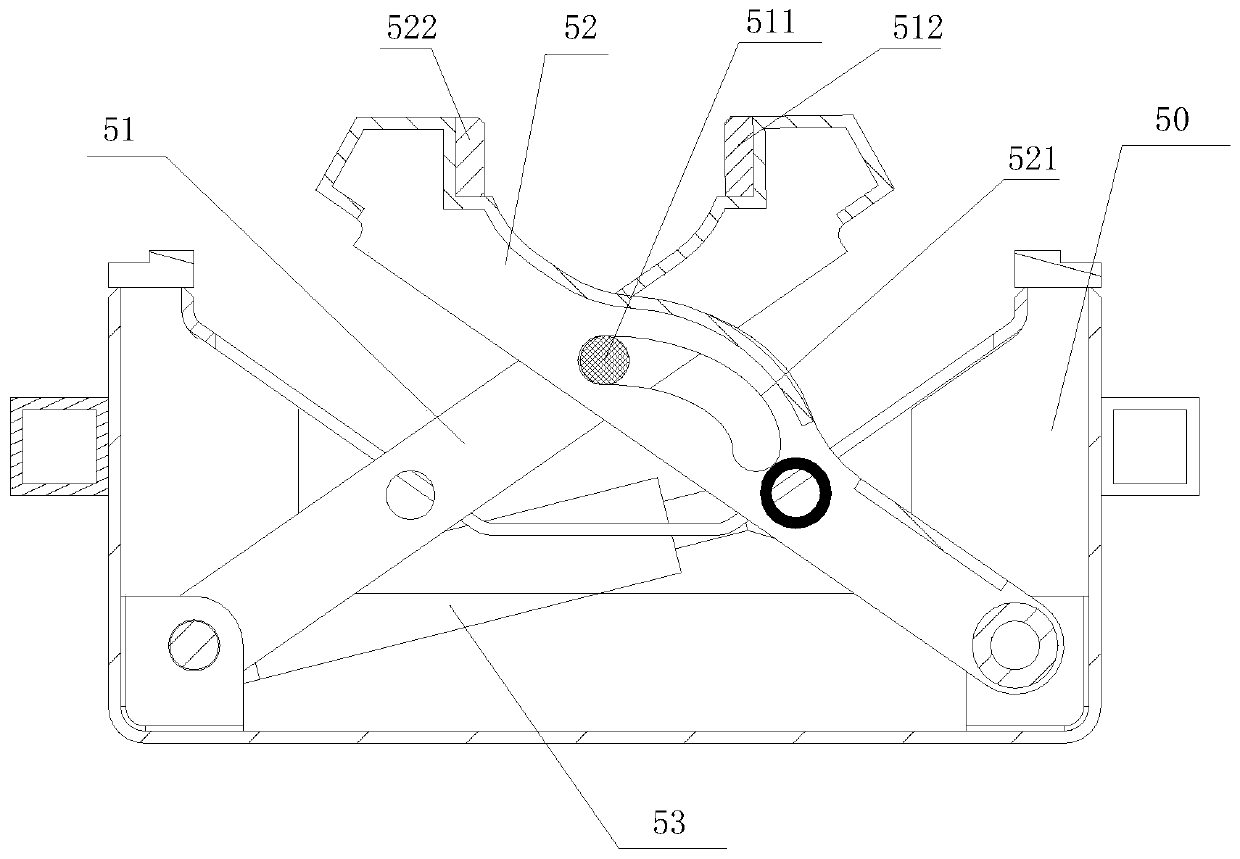

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] like figure 1 As shown, a large-aperture pressure relief drilling rig includes a mobile base 1, wherein the specific structure of the mobile base 1 is a currently known vehicle chassis, which is mainly used for the movement of the pressure relief drilling rig; it also includes: and the mobile base 1 The track unit 2 to which the slewing support 11 is connected. Wherein, the structure of the track unit 2 is the structure that pushes the front legs of the drill pipe in the pressure relief drilling rig in the prior art. In the current prior art, the track unit 2 is provided with a reciprocating mechanical movement part 3, wherein the main function of the mechanical movement part 3 is to use the track unit 2 to push the drill pipe forward, forcing the drill pipe to go directly into the rock formation, and at the same time Utilize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com