Electrospark wire-electrode cutting process discharge condition detecting device

A technology of discharge state and cutting processing, applied in measuring devices, measuring current/voltage, measuring electrical variables, etc., can solve problems such as deteriorating processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings.

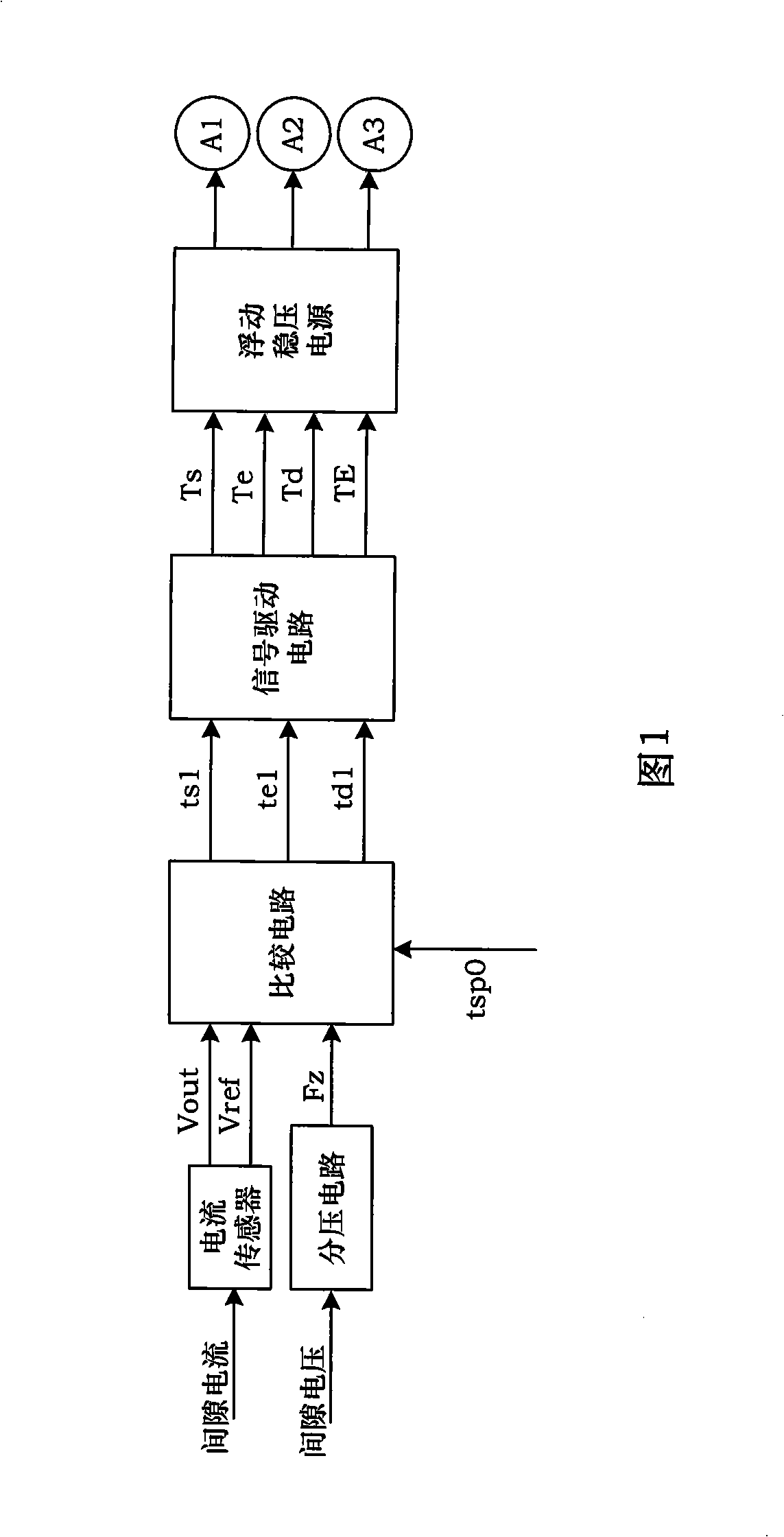

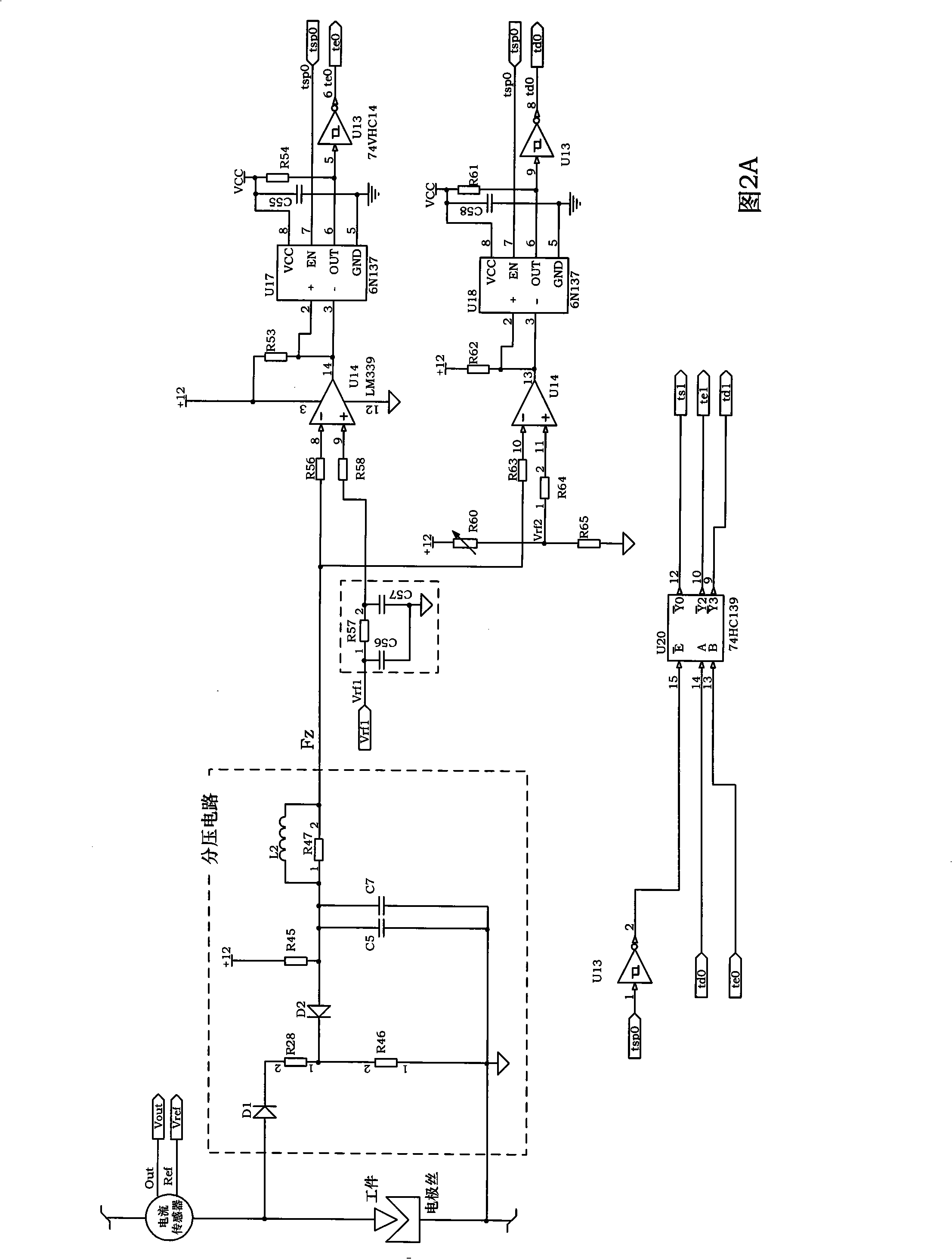

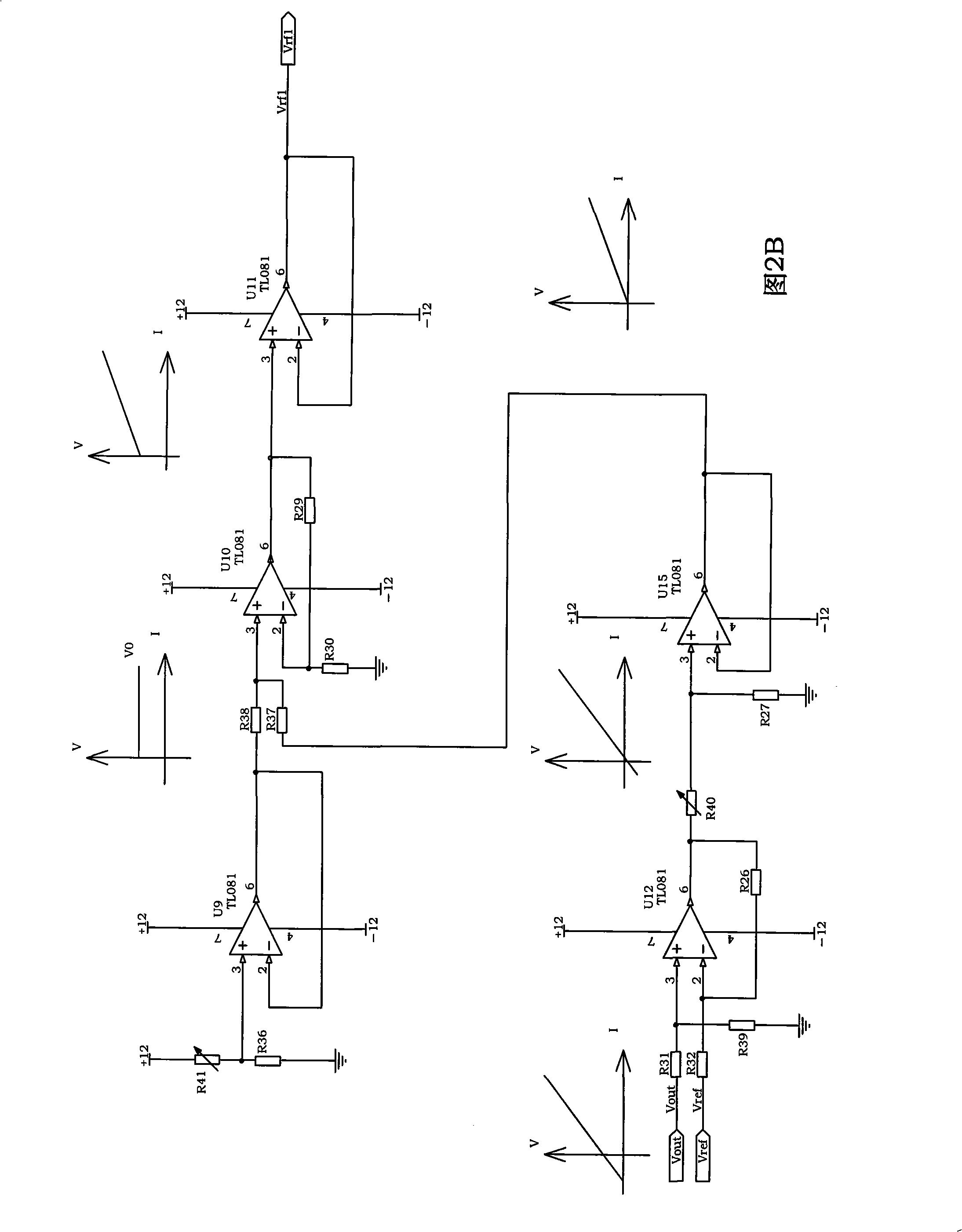

[0018] The invention relates to a discharge state detection device for wire electric discharge machining, which includes a voltage dividing circuit, a comparison circuit, a signal drive circuit, a floating voltage-stabilizing power supply circuit, and a current sensor. The current sensor is used to detect the gap current between the electrode (electrode wire or copper tube electrode) and the workpiece, and output the voltage Vout and reference voltage Vref corresponding to the measured current value to the voltage divider circuit.

[0019] The voltage divider circuit is used to detect the gap voltage between the electrode and the workpiece, and the gap voltage is processed by the voltage divider filter in the voltage divider circuit to output the divided voltage value Fz of the gap voltage to the comparison circuit.

[0020] The comparison circuit performs ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com