Low alloy steel

A low-alloy steel and metallographic structure technology, applied in the field of low-alloy steel, to achieve effective characteristics, improve high-temperature creep strength and long-term creep ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

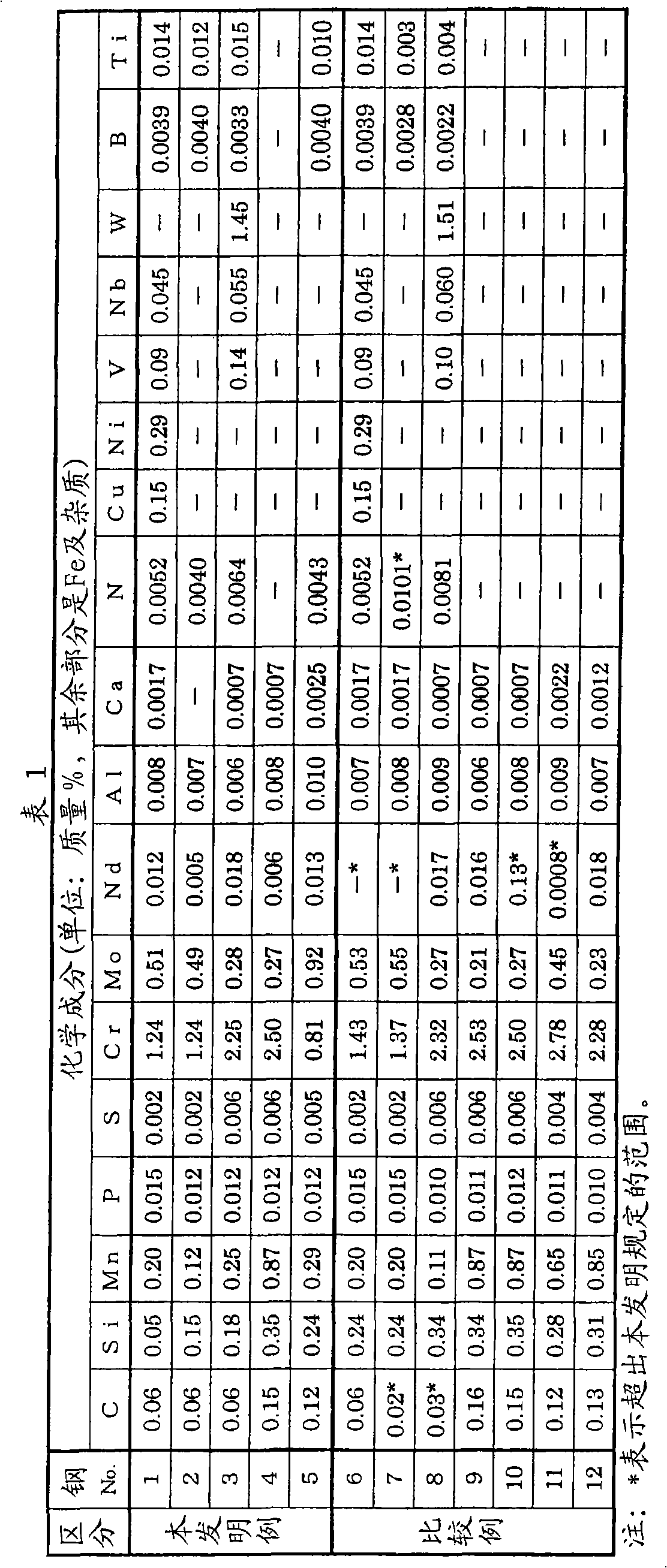

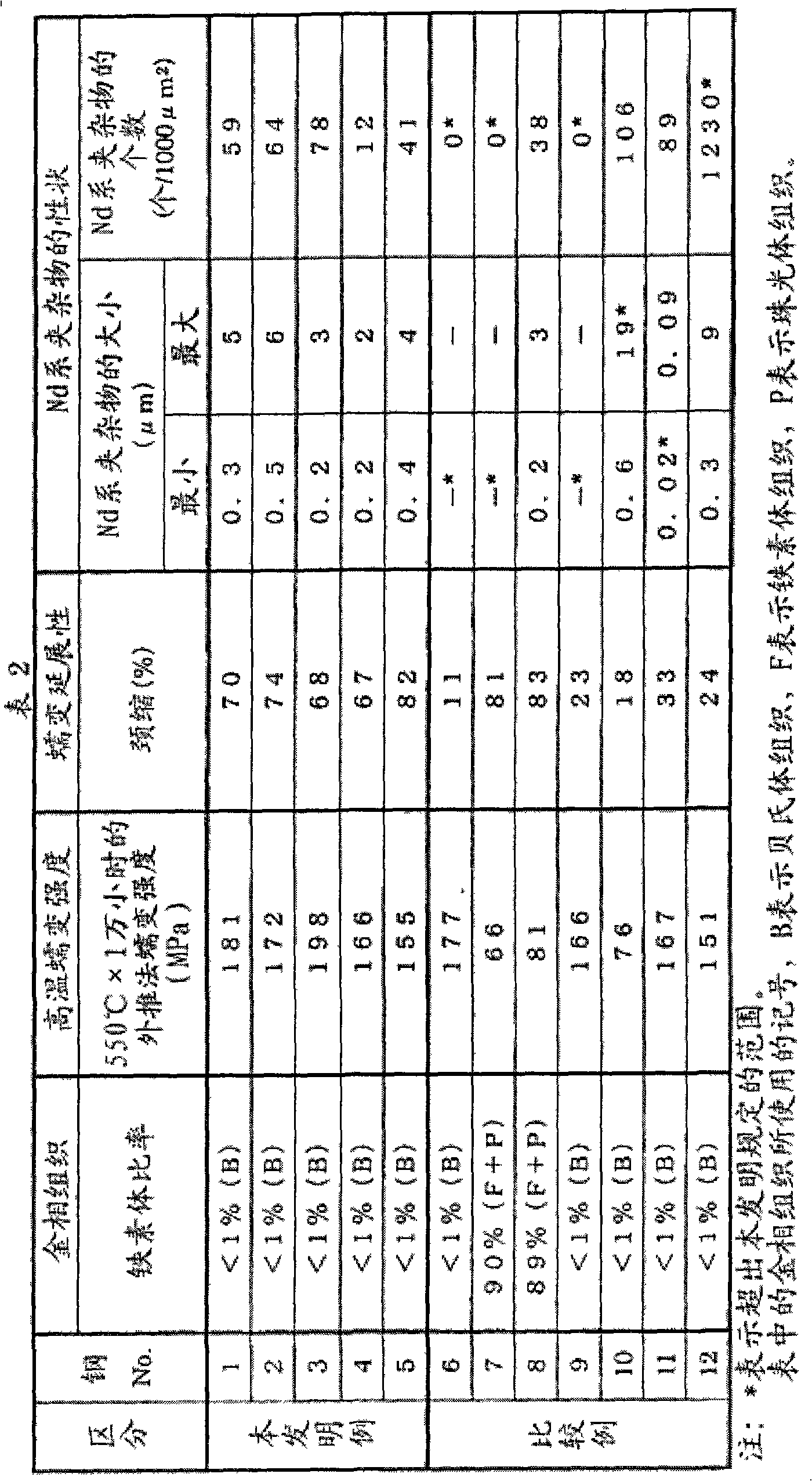

[0069] Twelve kinds of alloys having the chemical compositions shown in Table 1 were smelted in a vacuum induction melting furnace to obtain ingots with a diameter of 144 mm and 50 kg. When melting alloys, in order to control the properties of Nd-based inclusions, the method of deoxidation and Nd addition is changed.

[0070] In steel Nos. 8, 10 and 11 in the examples of the present invention (steel Nos. 1 to 5) and comparative examples, after adding Si iron and Mn iron, deoxidize with Al, then add Nd, and further add Mn-Si to for deoxygenation.

[0071] In Steel Nos. 6 and 7 in Comparative Examples, Nd was not added.

[0072] In steel No. 9 in the comparative example, after adding Nd, deoxidation was performed by adding Si iron, Mn iron, and Al. In addition, in steel No. 12 in the comparative example, Nd was added after deoxidation was performed by adding Si iron, Mn iron, and Al.

[0073] Table 1

[0074]

[0075] The obtained ingot was subjected to hot forging and ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| creep strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com