Construction method for complete casing tube thin wall filling pile and movable internal mold

A construction method and technology of cast-in-place piles, which are applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as unreliable construction quality, limited depth of immersed pipes, and high construction costs, and achieve pollution-free, fast, efficient, and low-cost construction. The amount of concrete and the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

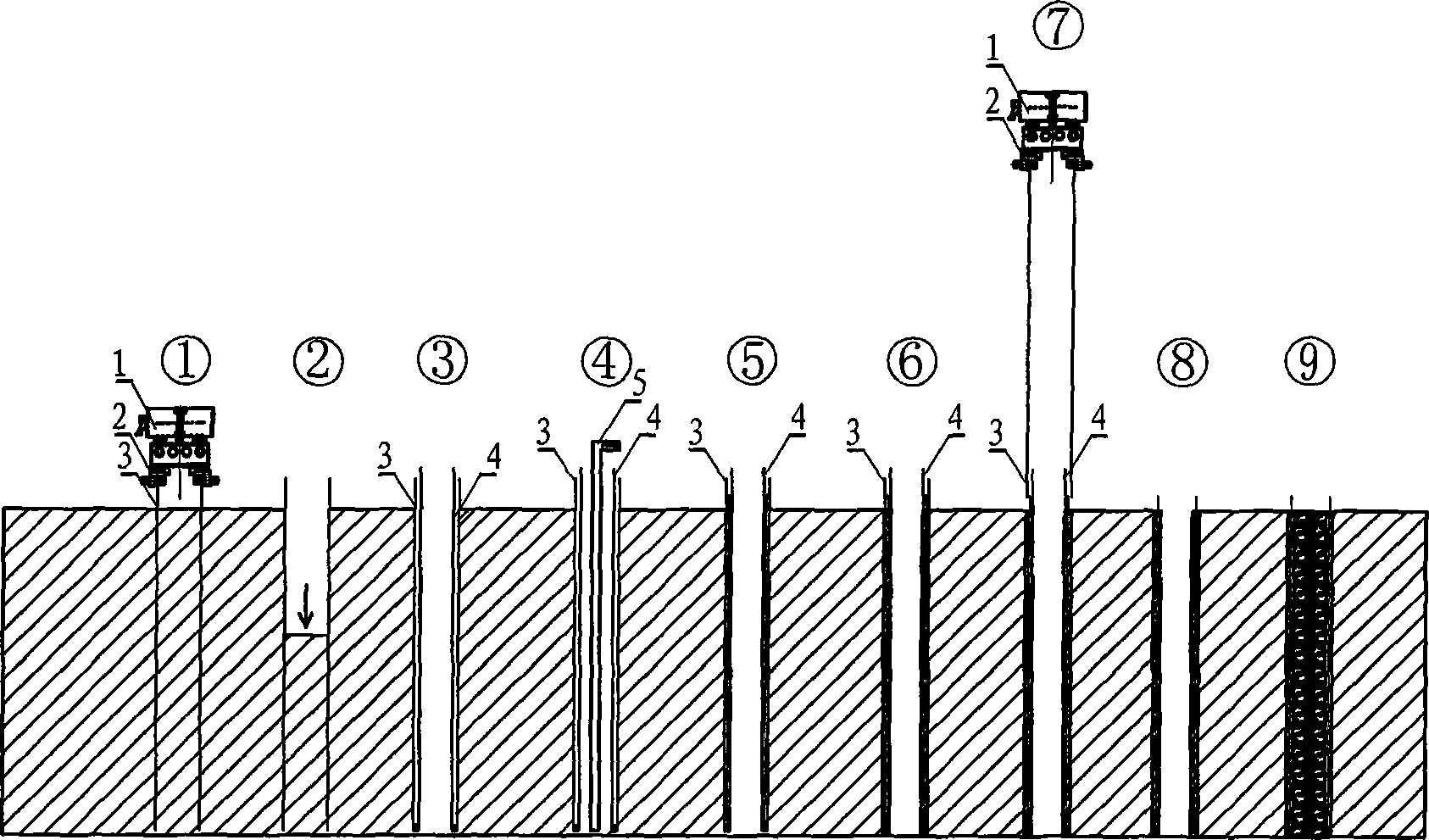

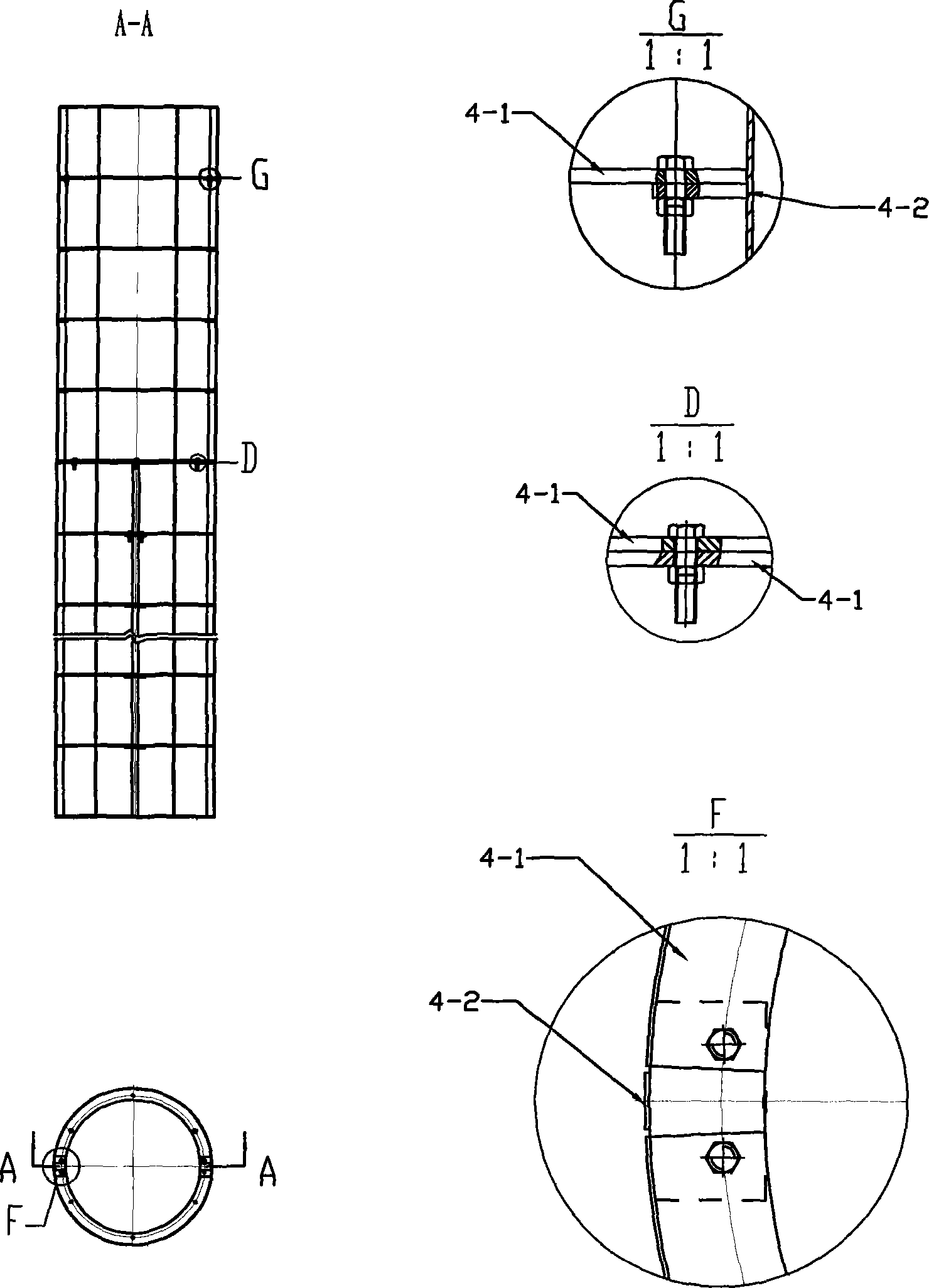

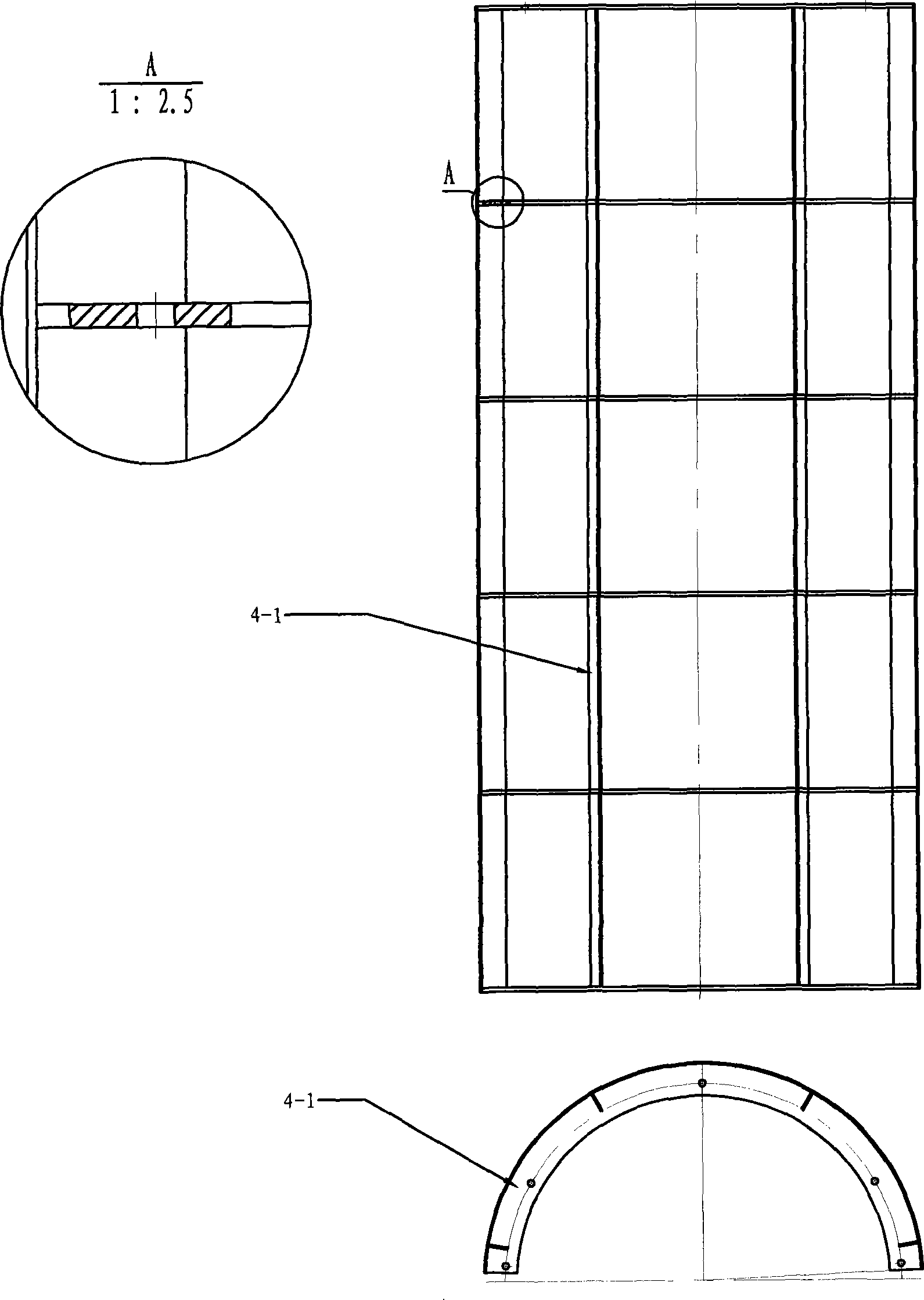

[0035] Example: such as figure 1 The construction method of the full-sleeved thin-wall cast-in-situ pile and the movable inner mold of the present invention have adopted equipment such as high-frequency vibration hammer 1, clamper 2, single-layer casing 3, movable inner mold 4 and mud pump 5, and the single-layer casing 3. Through the holder 2, it sinks into the foundation soil under the action of the medium and high-frequency vibrating hammer 1 with a large excitation force above 1000kN. The single-layer casing 3 adopts a full-length steel casing, which not only acts as a wall protection, but also as a thin-walled casing. One of the forming components of cast-in-situ piles; according to the softness and hardness of the soil, the soil in the single-layer casing is taken out by mechanical soil extraction or manual excavation; after the hole is accepted, the assembled movable inner mold 4 is hoisted into the hole Inside, after the position is adjusted and fixed, the subsequent w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com