Portion waveshape steel web plate pre-stress steel-concrete continuous combined case beam

A corrugated steel web, prestressed steel technology, applied in bridges, bridge materials, bridge construction and other directions, can solve the problems of complex construction, low efficiency of longitudinal prestressing bars, instability of flat steel webs, etc. It is convenient for factory production and erection construction, and the effect of easy assembly construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

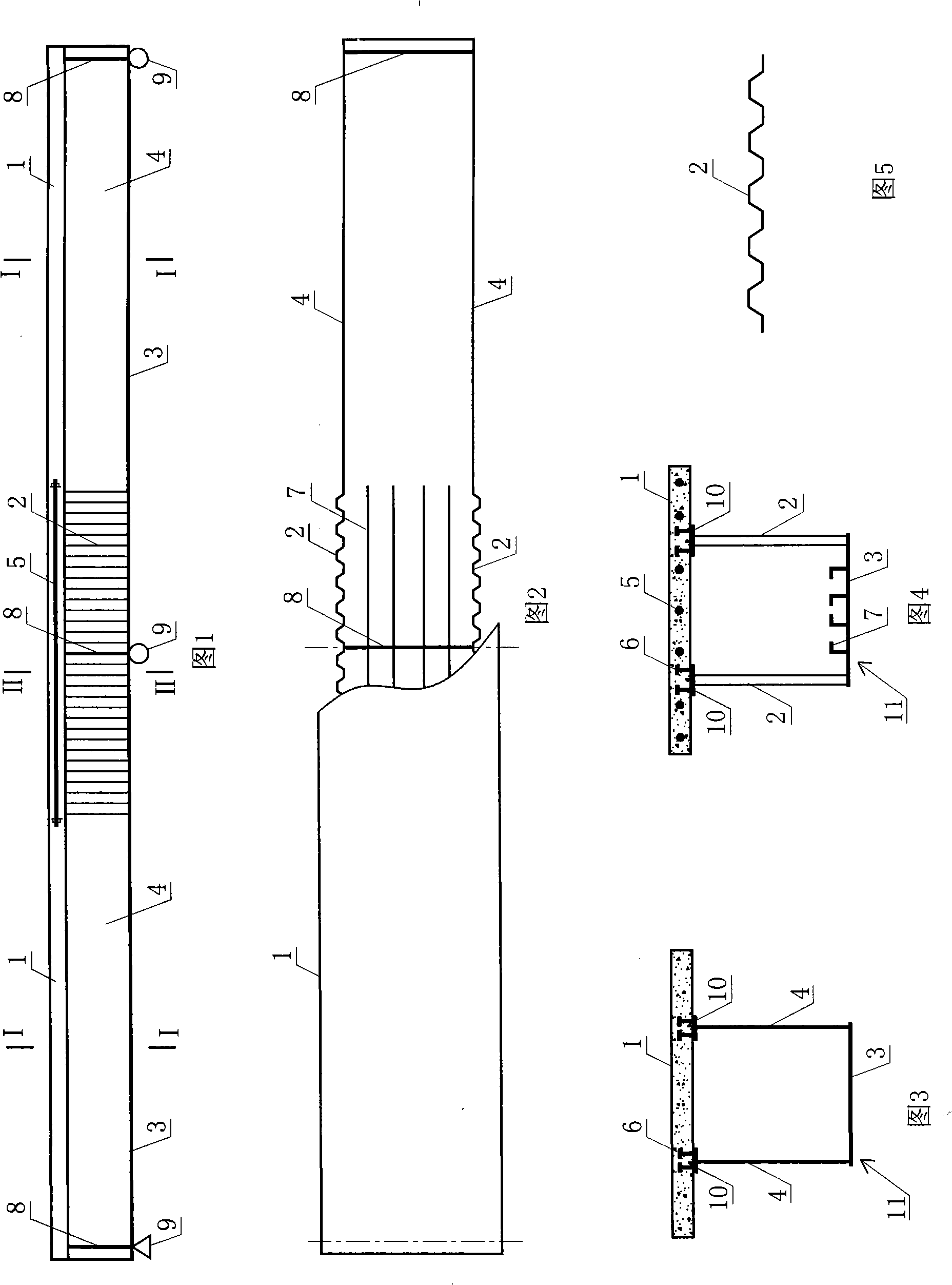

[0024] As shown in Fig. 1 to Fig. 4, the part corrugated steel web prestressed steel-concrete continuous composite box girder of the present invention comprises the steel box girder 11 that steel web on both sides and steel bottom plate 3 are formed, and concrete top plate 1 is contained in this steel box girder. The top of the box girder 11 is fixedly connected with the steel box girder 11 with the connecting steel plate 10 and the shear member 6. In the steel box girder 11, steel transverse diaphragms 8 are respectively installed at positions corresponding to the fulcrums 9 at the bottom of the steel box girder. The overall steel box girder 11 is composed of a structural negative moment zone segment located in the middle section and a structural positive moment zone segment located at both ends of the structural negative moment zone segment. The concrete in the structural negative moment zone segment The longitudinal prestressed tendons 5 are stretched in the top plate 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com