Method for treating dehydrated sludge of domestic sewage treatment plant

A technology for dewatering sludge and domestic sewage, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc. High problems, to achieve the effects of low capital investment and treatment costs, short curing time, and simple curing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Sludge solidification treatment in a large domestic waste landfill in Shanghai.

[0021] The dewatered sludge comes from a domestic sewage treatment plant in Shanghai, with a moisture content of 73.3% and a compressive strength of 8.3kPa.

[0022] The composition and weight percentage of curing agent are: MgO is 80%, MgCl 2 20%. MgO is industrial-grade light or heavy magnesium oxide powder, with an effective content of 75%; MgCl 2 For industrial grade, the effective content is 46%. Mix the curing agent in the storage tank, and then enter the powder silo for use.

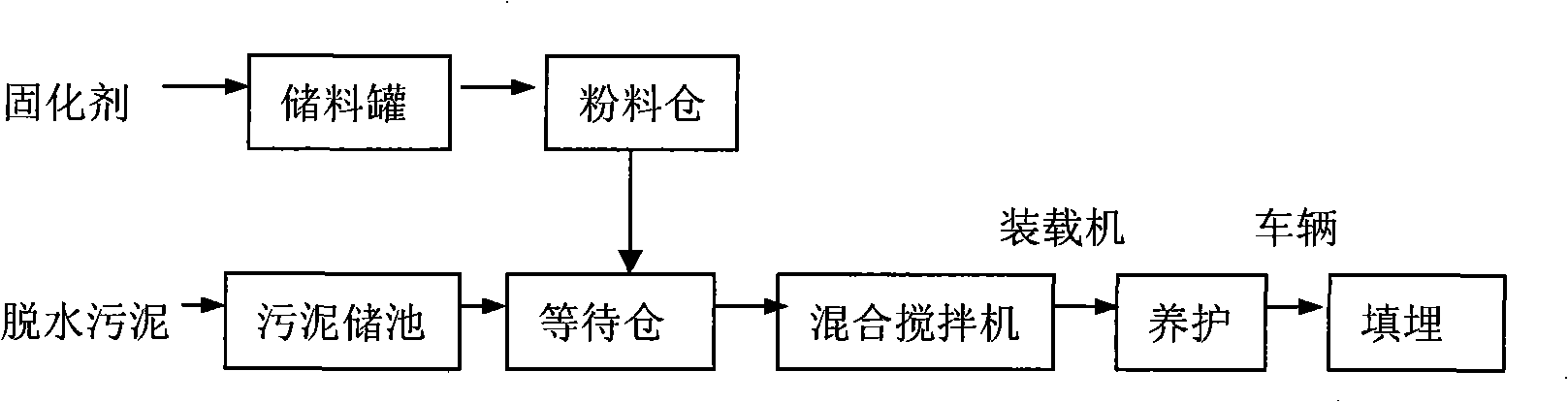

[0023] The dewatered sludge is stored in the sludge storage tank, and then the dewatered sludge measured in the above ratio is sent into the waiting bin by a hoist according to dewatered sludge: curing agent = 95%: 5% by weight. Add the curing agent in the powder silo to the dewatered sludge. Then mix and stir the dewatered sludge and curing agent for 3 minutes in a mixing mixer, and then discharge the ma...

Embodiment 2

[0025] In addition to the composition and weight percentage of the curing agent: MgO is 85%, MgCl 2 15%; Dewatered sludge: solidifying agent=92%: except 8% weight percentage, all the other are identical with embodiment 1. The properties of the solidified sludge are listed in Table 1.

Embodiment 3

[0027] In addition to the composition and weight percentage of the curing agent: MgO is 75%, MgCl 2 25%; Dewatered sludge: curing agent=88%: except 12% by weight, all the other are identical with embodiment 1. The properties of the solidified sludge are listed in Table 1.

[0028] Table 1 Properties of solidified sludge

[0029]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com