Portable electric tool with braking device

A technology for hand-held machine tools and braking devices, which is applied in the directions of manufacturing tools, electromechanical devices, and electric components, and can solve problems such as increasing expenses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

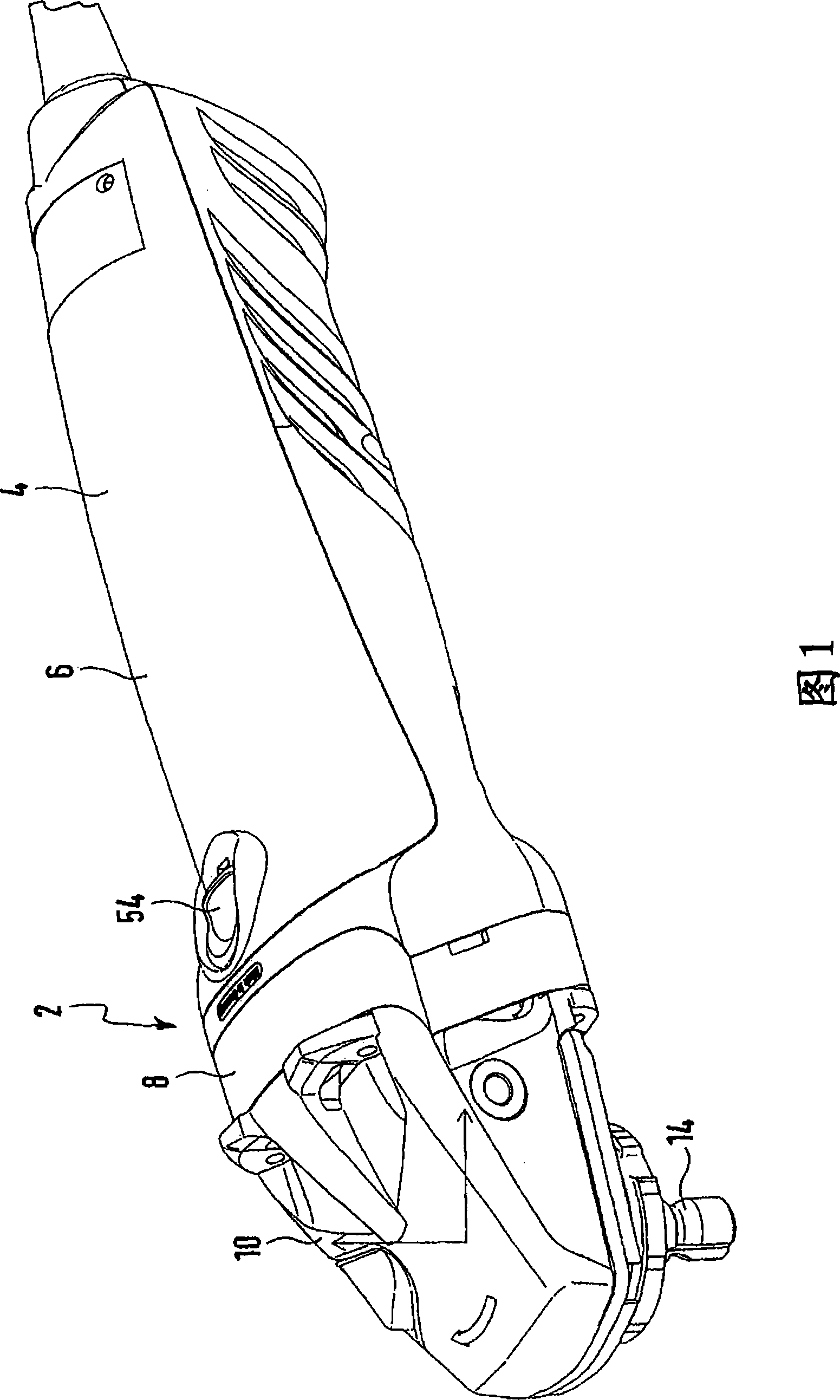

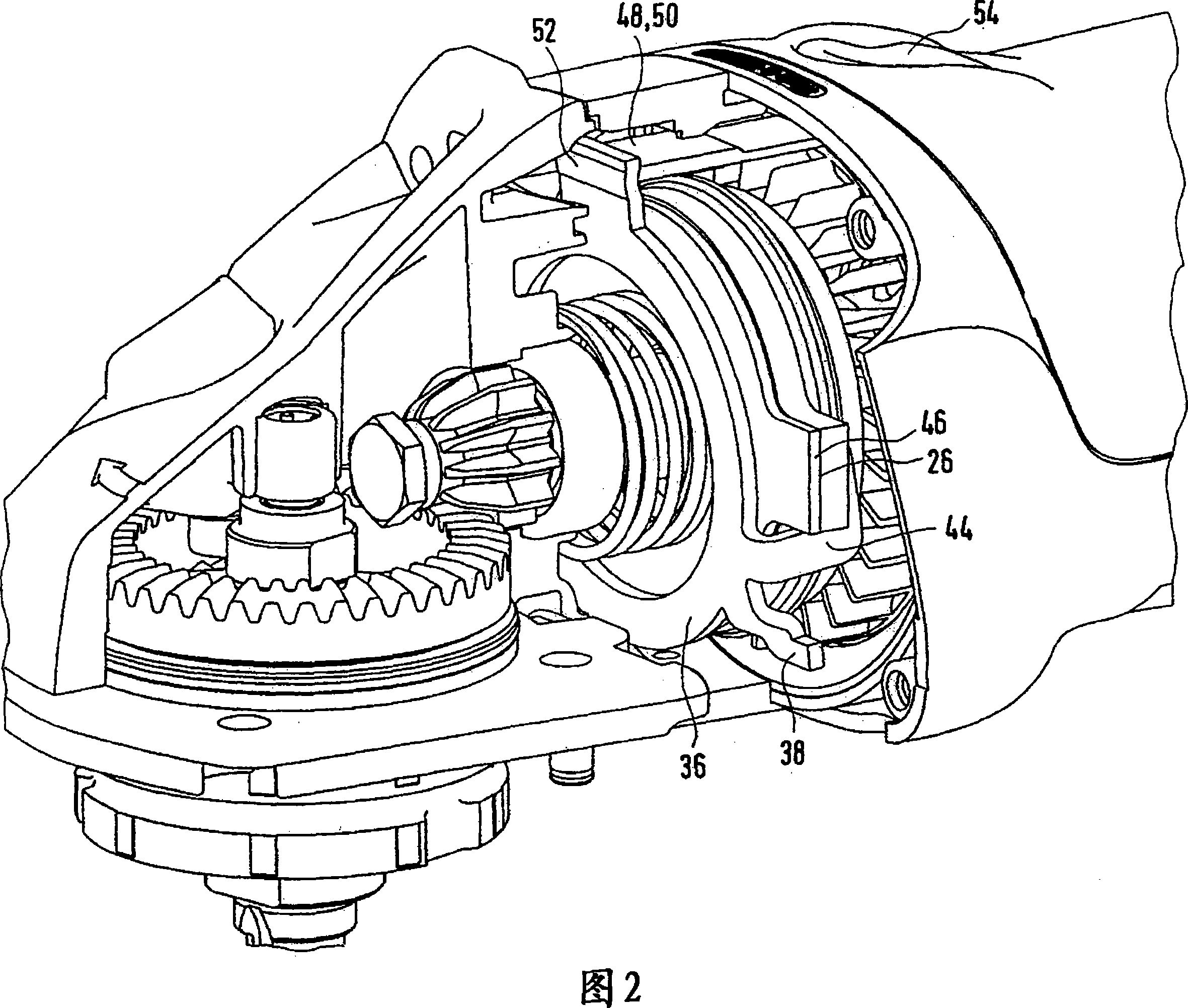

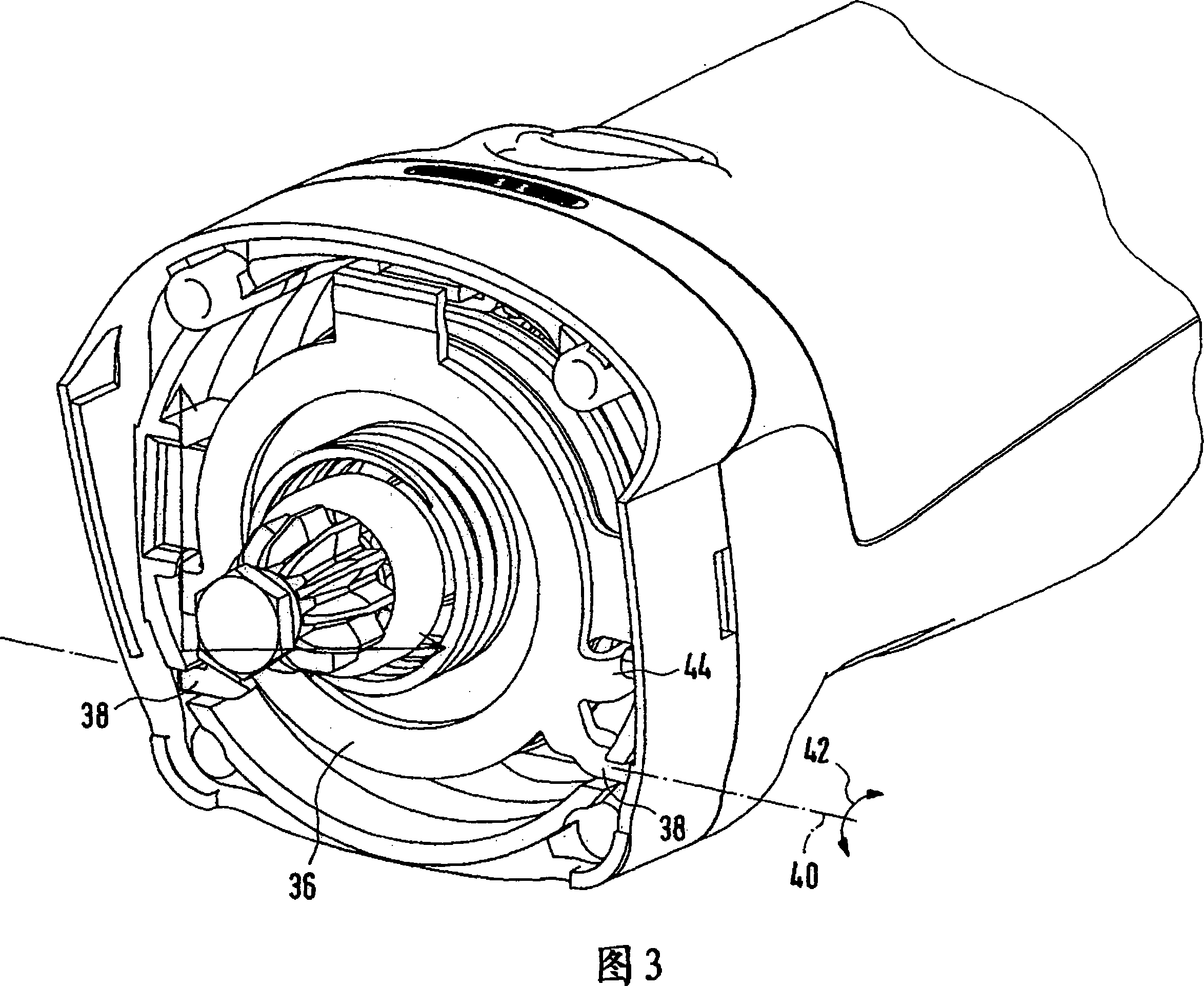

[0025] The drawing shows an electric hand-held power tool in the form of an angled-handle hand grinder or cutting machine, which is designated as a whole by the reference number 2 . The machine tool comprises a handle part 4 and a transmission housing part 10, wherein the handle part 4 simultaneously forms a motor housing part 6 and is connected to an intermediate housing flange 8 not yet described in detail, the tool spindle 14 is perpendicular to the longitudinal center axis 12 of the machine tool Ground (see FIG. 4 ) extends outwardly from mechanism housing member 10 . A grinding wheel or a cutting tool is fastened on the spindle 14 in a known manner.

[0026] A transmission shaft 18 extends from the electric motor 16 in the direction 12 of the longitudinal center axis through the intermediate housing flange 8 into the transmission housing part 10 . The drive shaft 18 drives the tool spindle 14 via a bevel gear 20 .

[0027] Between the motor housing part 6 and the transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com