Catalyst for preparing propylene with ethylene and butene inverse-disproportionation and method of preparing the same

A catalyst and butene technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of complex catalyst preparation methods, and achieve the effects of superior stability, simple preparation methods and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

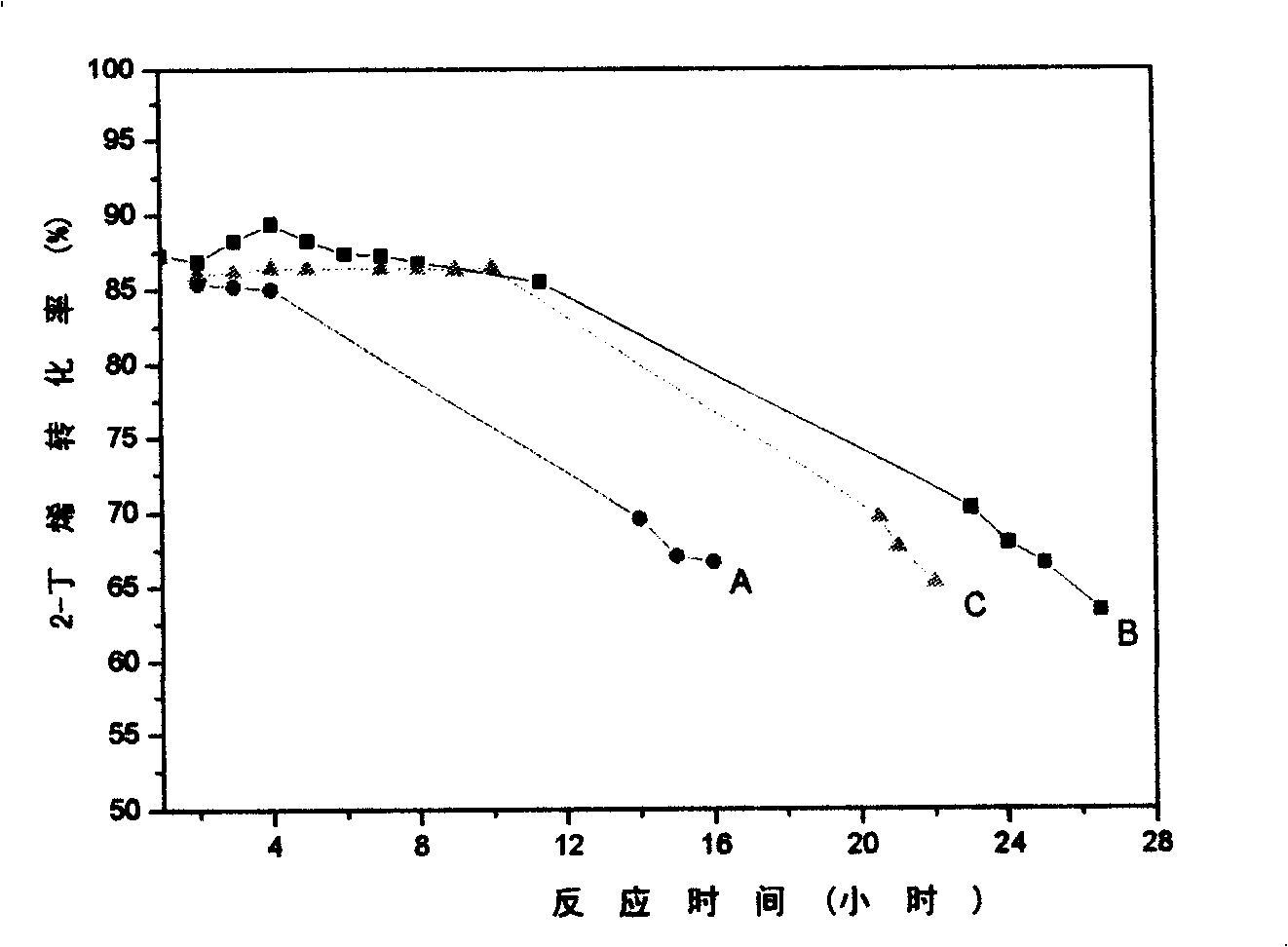

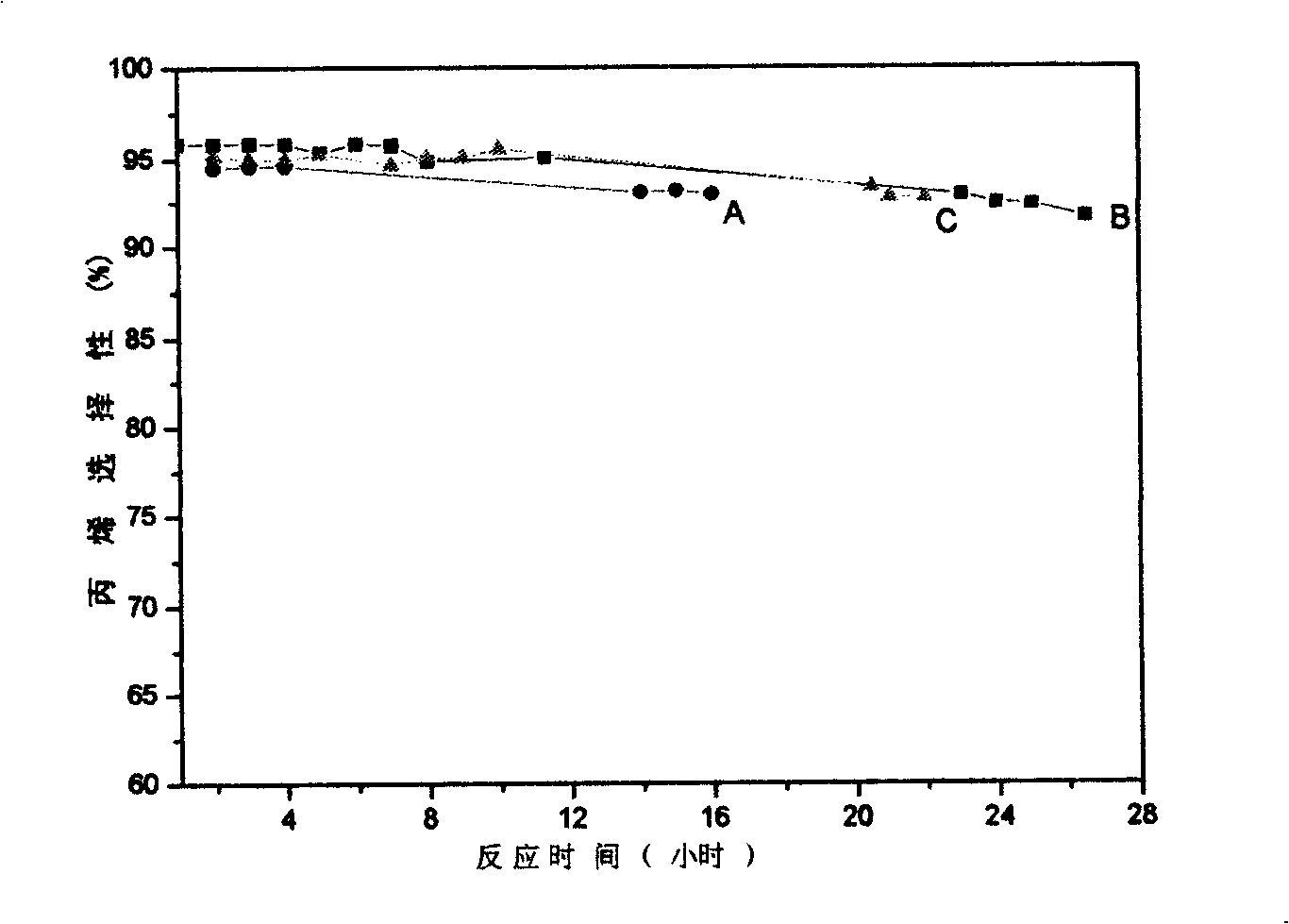

Embodiment 1

[0025] Weigh 2g of SBA series molecular sieves, add aluminum nitrate dissolved in ethanol, and dry the carrier in an oven at 120°C for 24 hours after natural air drying. After being calcined at 550° C. for 2 hours under flowing air, it is pressed into tablets to obtain a composite carrier with a certain particle size. Weigh 2.45g of the obtained SBA-A carrier, add 4ml of ammonium molybdate aqueous solution, impregnate for 30 minutes, dry in air for 24 hours, then put the above sample into a muffle furnace, heat up to 600°C and bake for 2 hours under flowing air , A catalyst with a Mo content of 8wt% was obtained after cooling.

Embodiment 2

[0027] Weigh 2g of SBA series molecular sieves, add 2g of alumina, mechanically grind and mix, place in a muffle furnace for calcination at 550°C for 2 hours, and press into tablets to obtain a composite carrier with a certain particle size. Weigh 2.45g of the obtained SBA-B carrier, add 4ml of ammonium molybdate aqueous solution, soak for 30 minutes, dry in air for 24 hours, then put the above sample into a muffle furnace, heat up to 600°C for 2 hours under flowing air , after cooling, the B catalyst with Mo content of 8wt% was obtained.

Embodiment 3

[0029] Weigh 2g of SBA series molecular sieves, add 1g of alumina, mechanically grind and mix them in a mortar, put them in a muffle furnace and bake them at 550°C for 2 hours under flowing air, and press them into tablets to obtain a composite carrier with a certain particle size. Weigh 2.45g of the obtained SBA-C carrier, add 4ml of ammonium molybdate aqueous solution, impregnate for 30 minutes, dry in air for 24 hours, then put the above sample into a muffle furnace, heat up to 600°C and bake for 2 hours under flowing air After cooling, the C catalyst with Mo content of 8wt% was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com