Conductive rubber having conducting wire evagination for test

A conductive rubber and wire technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems of inability to conduct tests or tests, failures, and reduced test pass rates, and achieve the effect of improving test pass rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

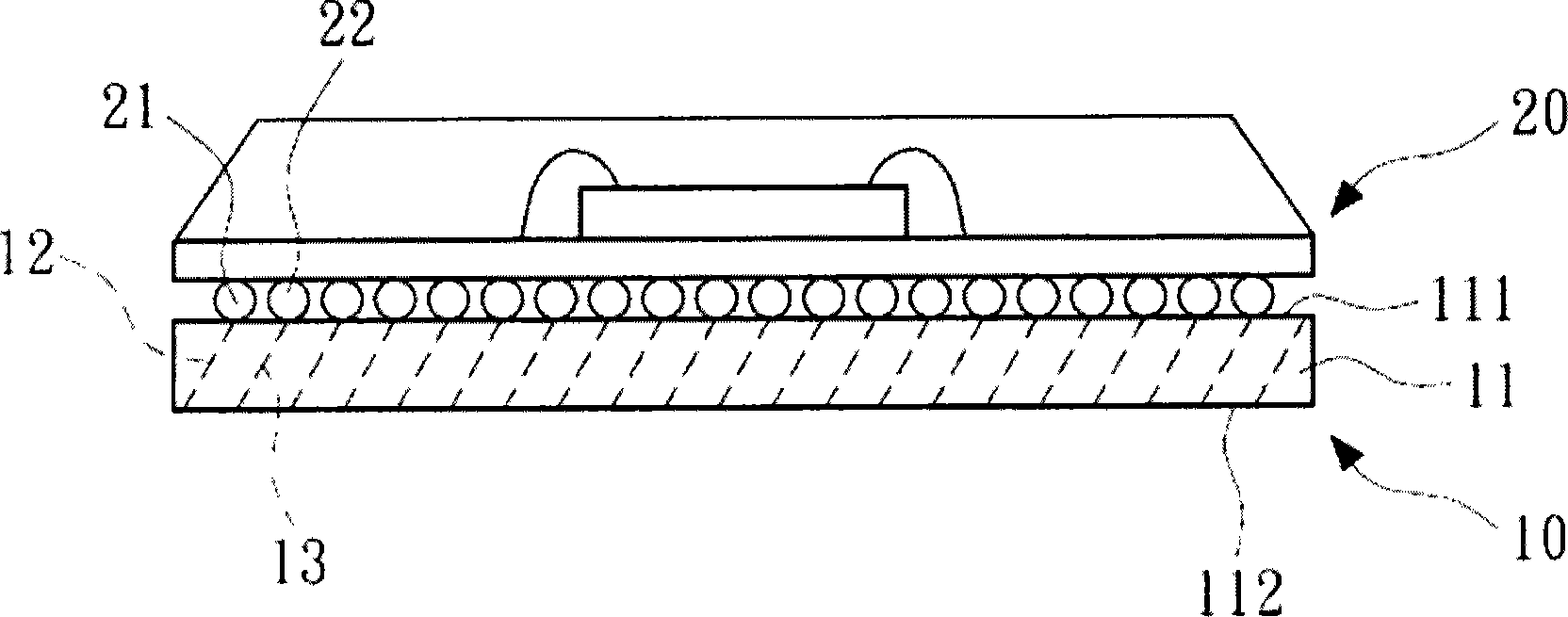

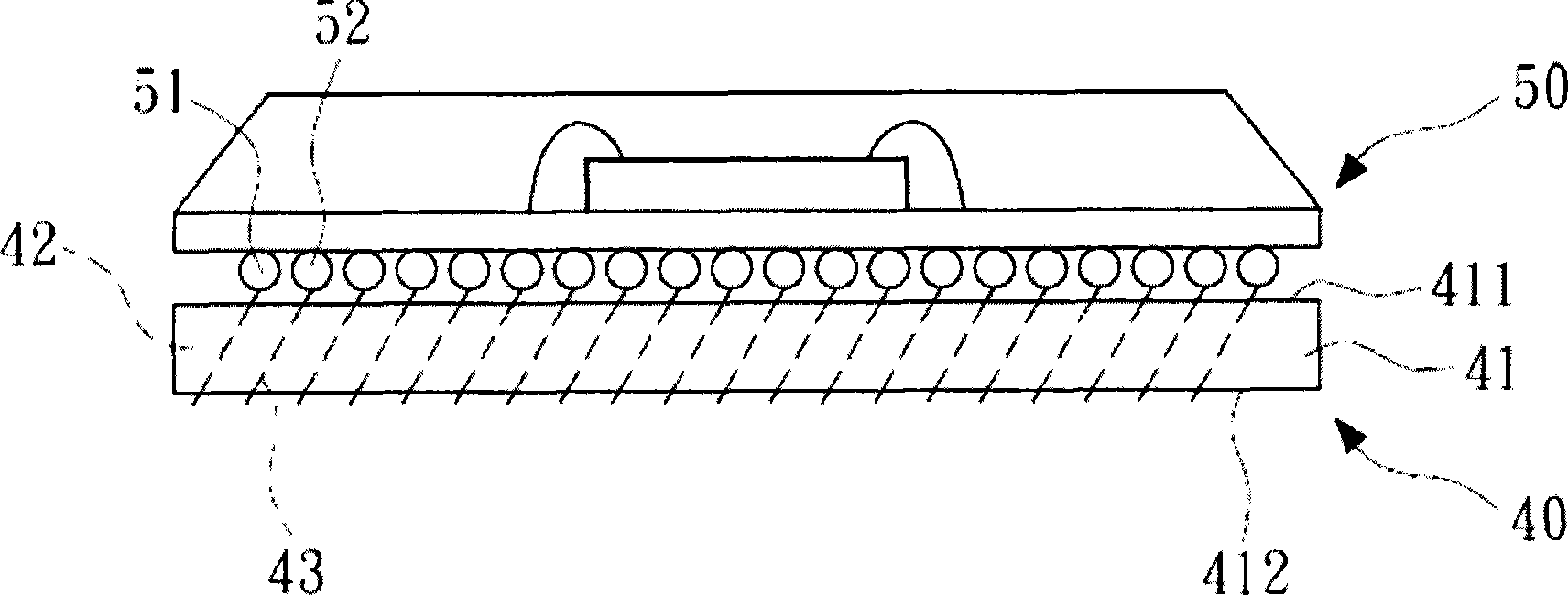

[0013] see image 3 , which shows a schematic diagram of the conductive rubber according to the first embodiment of the present invention. The conductive rubber 40 of the first embodiment of the present invention includes a rubber body 41 and several wires 42 , 43 . The rubber body 41 has a first surface 411 and a second surface 412 , and the second surface 412 is opposite to the first surface 411 . The conductive wires 42, 43 are arranged in the rubber body 41 and run through the first surface 411 and the second surface 412. The ends of the conductive wires 42, 43 protrude from at least the first surface 411 or the second surface 412. one of them.

[0014] That is, one of the ends of the wires 42, 43 protrudes from the first surface 411, or the other end of the wires 42, 43 protrudes from the second surface 412, or in this embodiment, the wires Both end points of 42 and 43 protrude from the first surface 411 and the second surface 412 .

[0015] The conductive rubber 40 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com