Sanding device for shaft neck of semi-shaft oil seal and sanding technology thereof

A journal and oil seal technology, which is applied in the field of sanding devices, can solve the problems of substandard roughness and oil leakage, and achieve the effect of improving the qualification rate and avoiding hidden dangers of oil leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

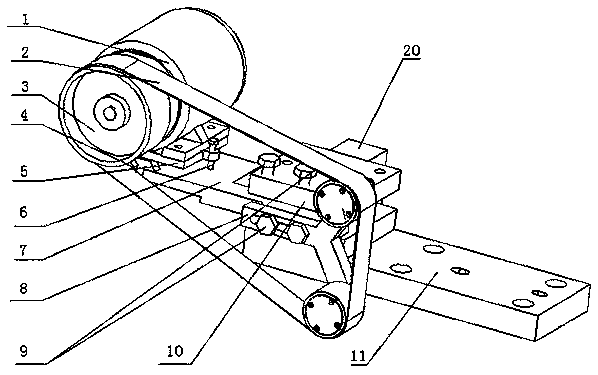

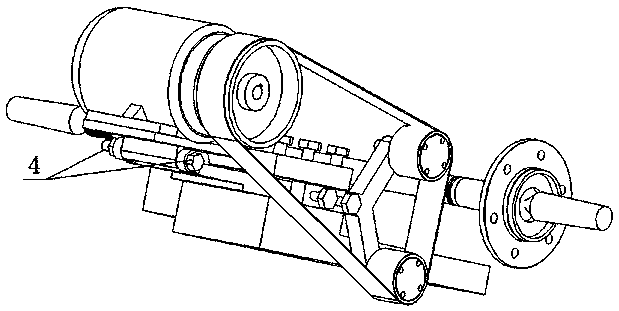

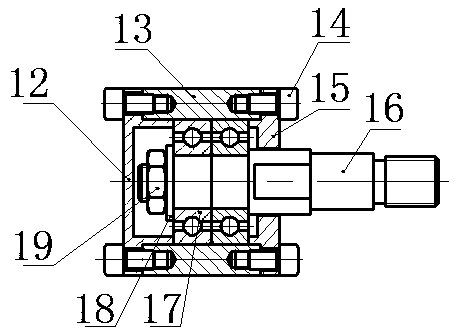

[0028] Example 1: see figure 1 —— Figure 5 The shown sanding device for the shaft journal of the half shaft oil seal includes a bottom plate 11, an abrasive belt 2, a driven wheel bracket 8, an electromagnetic brake motor 1, a time relay 20 and a switch K1, and the bottom plate 11 is provided with several The installation hole used to connect with the small supporting plate of the lathe, one end of the bottom plate 11 is provided with a step platform, the step platform is provided with a supporting plate 7, and the end of the supporting plate 7 away from the bottom plate 11 is installed with an electromagnetic brake motor 1 through the motor mounting plate 5 The time relay 20 is installed on the rear side of the base plate 11, and the electromagnetic brake motor 1 is connected to the time relay 20, the switch K1 and the power supply successively through the wires to form a closed loop, and the output shaft of the electromagnetic brake motor 1 is provided with a driving wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com