Enclosing-suction type combined kitchen tool

A technology of kitchen utensils and suction ports, which is applied in the field of surrounding suction combined kitchen utensils, which can solve the problems of wasting power, unhygienic, and moisture-prone items, and achieve the effects of good oil fume absorption, high cost performance, and novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

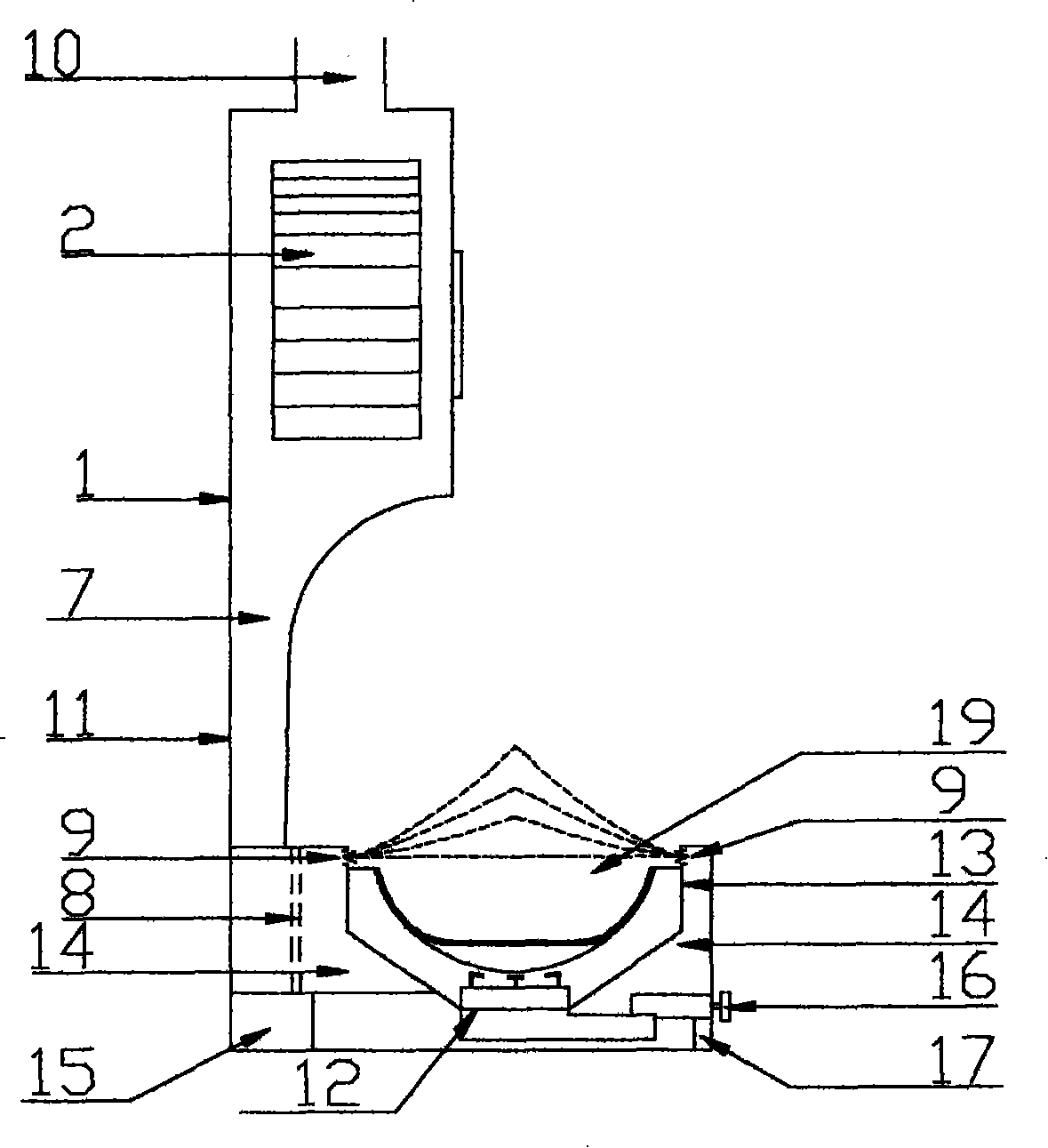

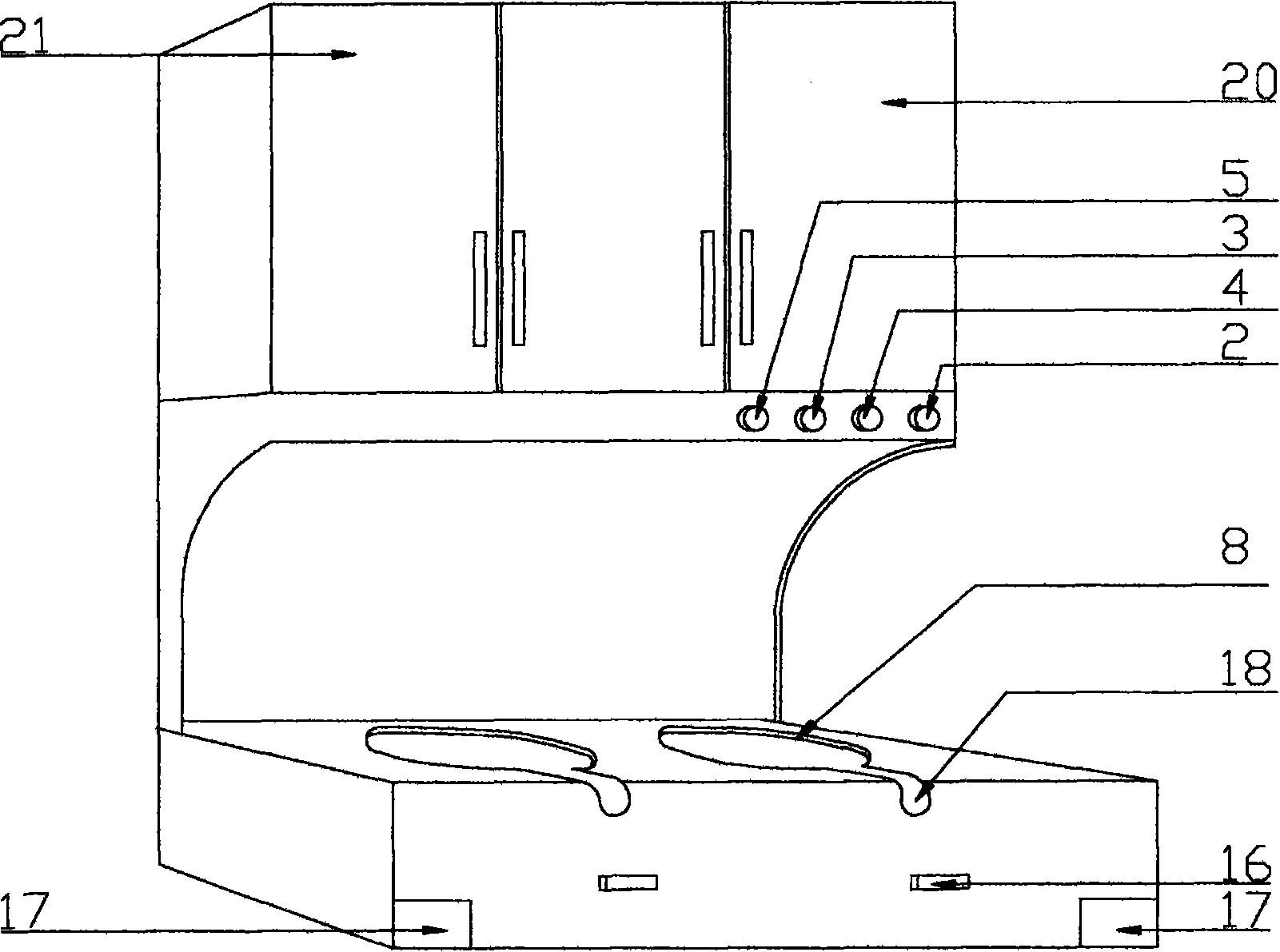

[0015] Implementation Mode 1: According to figure 1 , image 3 As shown, the fan is located on the top or rear of the gas cooker. Frame 1 is provided with blower fan 2, motor, control regulator and other supporting settings (not shown in the figure), and there is oil fume passage 7 connected with gas stove oil fume passage 14; Body middle part front is provided with power switch 2, left wind force key 3, right wind force key 4, delay key 5 and light key, is provided with disinfection cabinet 20, locker 21 beside fan frame body, also can establish a decorative plate to blow fan Outer frame and exhaust pipe cover. The inner bottom of the circular concave wall 13 of the gas stove frame 11 is processed with a combustion cooker 12, and the upper edge of the circular concave wall 13 is processed with ring-shaped suction ports 9, and the oil storage box 15 is arranged on both sides of the gas stove frame. Box drawer face 17 is processed in frame body front bottom, and its front to...

Embodiment approach 2

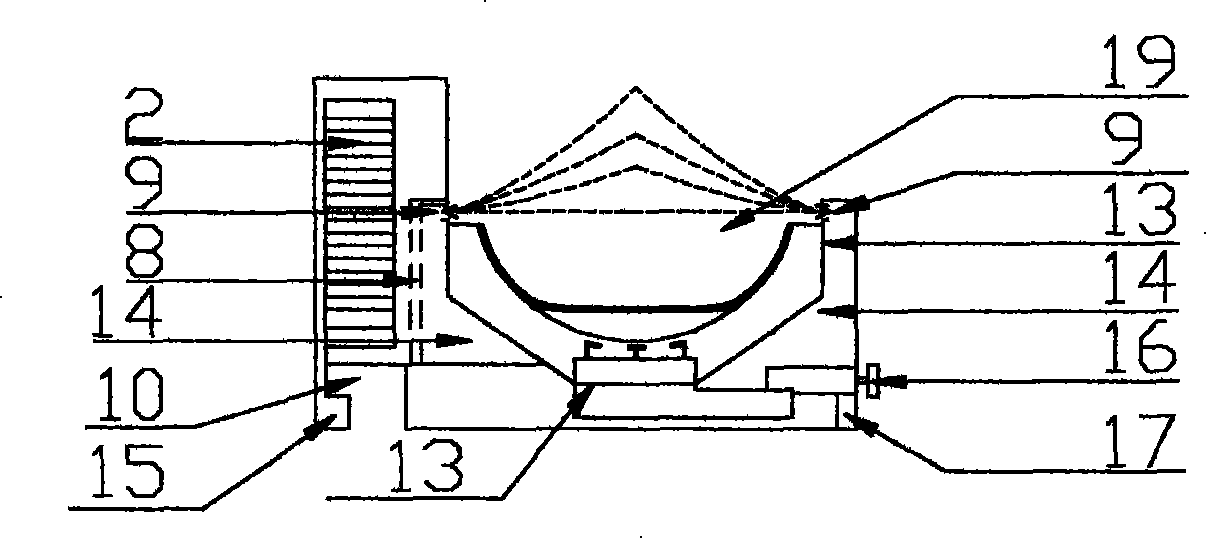

[0016] Implementation mode two: according to figure 2 , Figure 4 shown, with figure 1 , image 3 The main difference is: the wind wheel 2 is arranged at the rear position of the gas stove; the oil smoke outlet 10 is processed at the lower end of the oil smoke device, which is a lower row type. The height ratio between the range fume device and the gas stove of this style can be changed to a variety of styles, and can also be set to side row, rear row, top row and other styles [not shown in the figure], and can also be used on the gas stove A device protruding forward is provided with one or more suction ports on the lampblack device higher than a certain ratio. The rear row type can be set as a style that directly discharges the oil fume out of the wall. In this style, the oil fume device can also be installed in whole or in part in the window or wall near the back of the gas stove to reduce the placement area of the gas stove. This style also can be when the range fum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com