Method for improving yield of acetone, butanol and ethanol produced by fermentation of manioc materials

A raw material and tuber technology, which is applied in the field of improving the yield of acetone, butanol and ethanol produced by fermentation of potato raw materials, can solve the problems of high cost, effective utilization of potato raw materials, and low yield, so as to reduce the cost of raw materials, The effect of alleviating the shortage of food resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

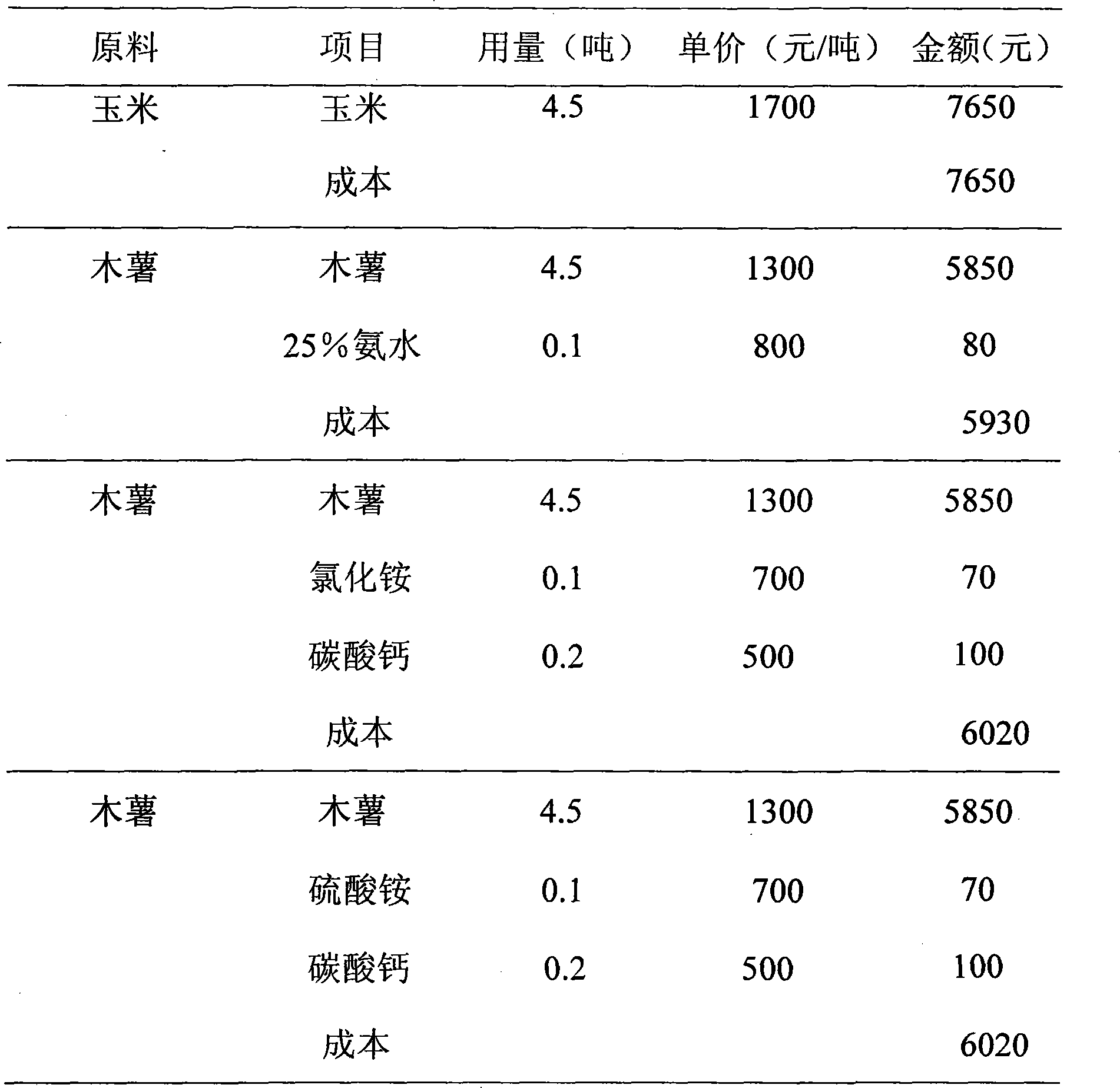

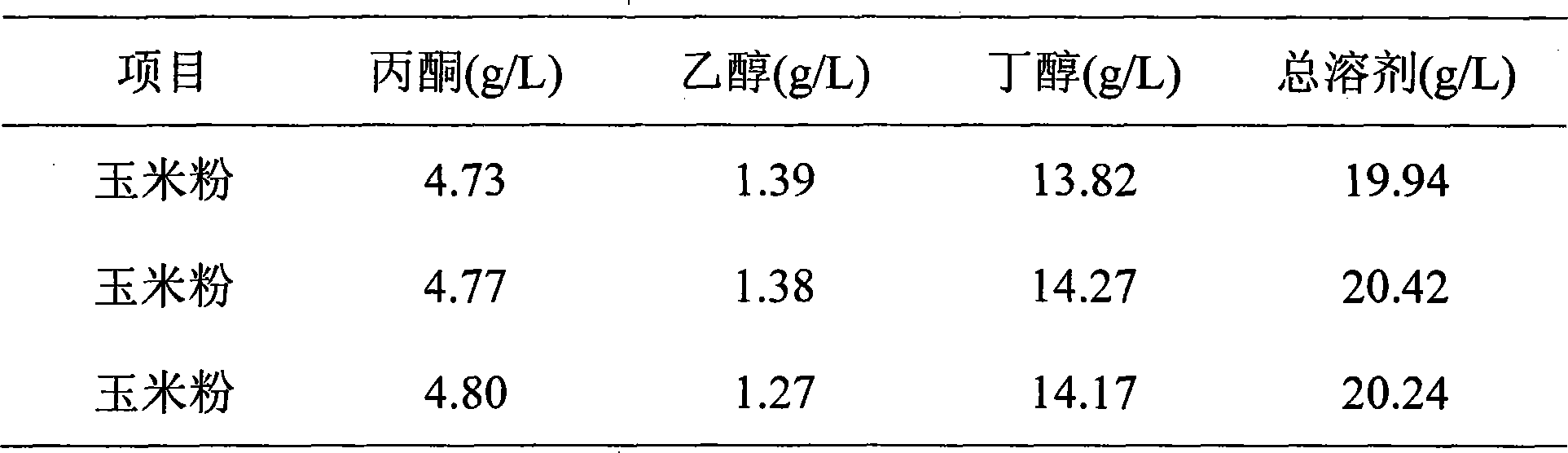

[0029] Embodiment 1: corn raw material fermentation

[0030] Weigh 80 grams of corn flour, add water to gelatinize for about 1 hour, set the volume to 1 liter, and then divide it into 500ml triangular flasks with a liquid volume of 60%. After filling, sterilize at 121°C for 1.5 Hour.

[0031] The medium was cooled to about 37°C, and the EA2018 strain in the test tube was inserted into the medium, and fermented in a 37°C incubator for 48 hours.

[0032] After the fermentation was finished, the fermented liquid was centrifuged at 12,000 rpm for 5 minutes, and the contents of acetone, butanol and ethanol were determined by gas chromatography after taking out. The solvent determination results are shown in Table 1.

[0033] Table 1 Fermentation results of corn medium

[0034]

[0035] From the results in Table 1, it can be seen that the ABE strain can be fermented normally in the corn culture medium, and the solvent yield is about 20g / L.

Embodiment 2

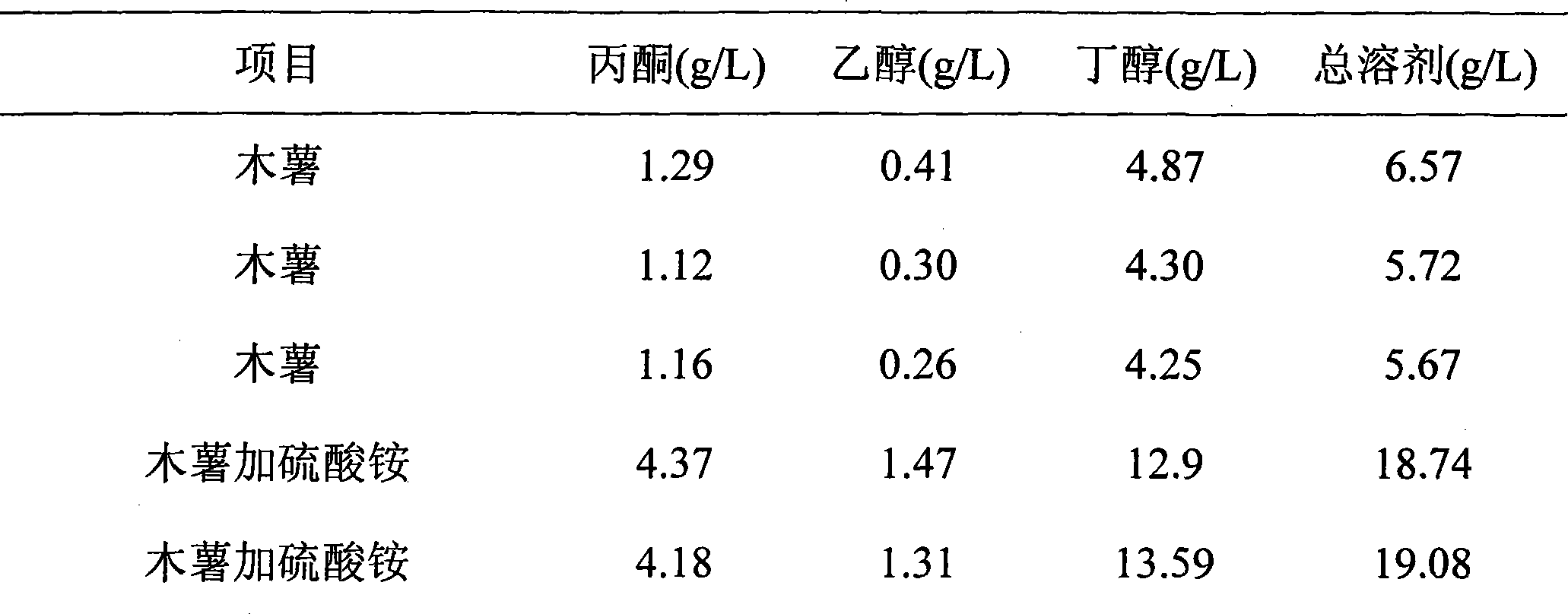

[0036] Example 2: Comparison of pure potato raw material fermentation and potato raw material fermentation after nitrogen source supplementation

[0037] Weigh 80 grams of cassava flour, 80 grams of sweet potato flour, 80 grams of potato flour, a mixture of 30 grams of sweet potatoes and 50 grams of cassava, add water to gelatinize for about 1 hour, set the volume to 1 liter, and then pack it into a 500ml triangle In the bottle, the liquid content is 60%. After filling, it is sterilized in a sterilizing pot at 121°C for 1.5 hours.

[0038] Take by weighing 80 grams of cassava flour, 80 grams of sweet potato flour, 80 grams of potato flour, a mixture of 30 grams of sweet potato and 50 grams of cassava, add 2.4 grams of ammonium sulfate, 3.6 grams of calcium carbonate, add water and gelatinize for about 1 hour, respectively The volume is fixed to 1 liter, and then divided into 500ml Erlenmeyer flasks with a liquid volume of 60%. After packing, sterilize at 121°C for 1.5 hours in...

Embodiment 3

[0045] Example 3: Mixed fermentation of potato and corn and mixed fermentation after nitrogen source supplementation

[0046] Weigh two parts of 24 grams of tapioca flour and 56 grams of corn flour (mixture 1, cassava accounts for 30%), one of which is supplemented with 2.4 grams of ammonium sulfate and 3.6 grams of calcium carbonate.

[0047]Weigh two parts of 48 grams of tapioca flour and 32 grams of corn flour (mixture 2, cassava accounts for 60%), one of which is supplemented with 2.4 grams of ammonium sulfate and 3.6 grams of calcium carbonate.

[0048] Weigh two parts of 32 grams of sweet potato flour and 48 grams of corn flour (mixture 3, sweet potato accounts for 40%), one of which is supplemented with 2.4 grams of ammonium sulfate and 3.6 grams of calcium carbonate.

[0049] The above 6 parts were gelatinized with water for about 1 hour, respectively fixed to 1 liter, and then distributed into 500ml Erlenmeyer flasks with a liquid volume of 60%. After packing, they we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com