Method for coal desulfurization catalyzed by microwave

A microwave catalysis and coal technology, which is applied in the field of coal desulfurization, can solve the problems of desulfurization technology that does not destroy the coal matrix structure, has no high desulfurization efficiency, and is limited in the scope of application, so as to improve the quality of coal and the scope of use, and achieve good promotion and application value. , the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

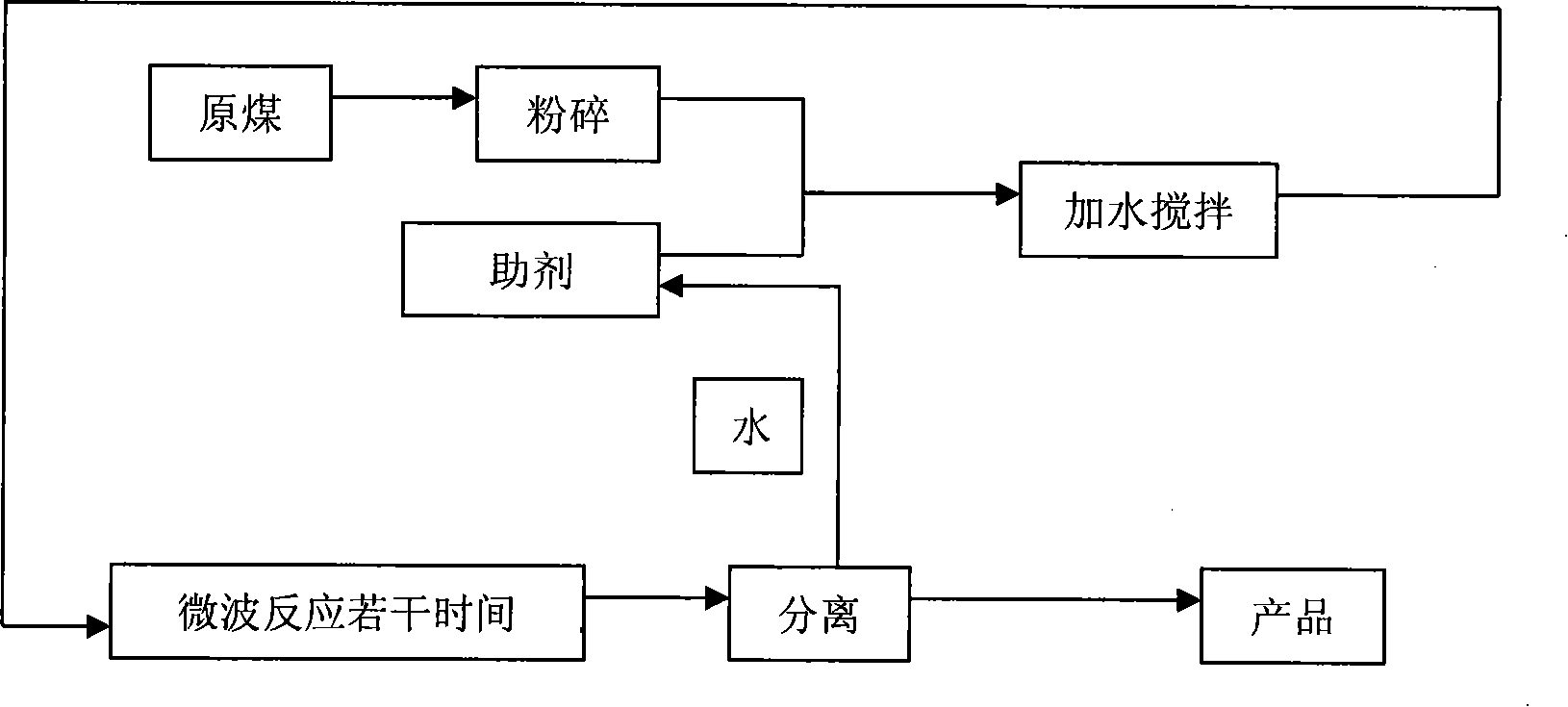

Method used

Image

Examples

Embodiment 1

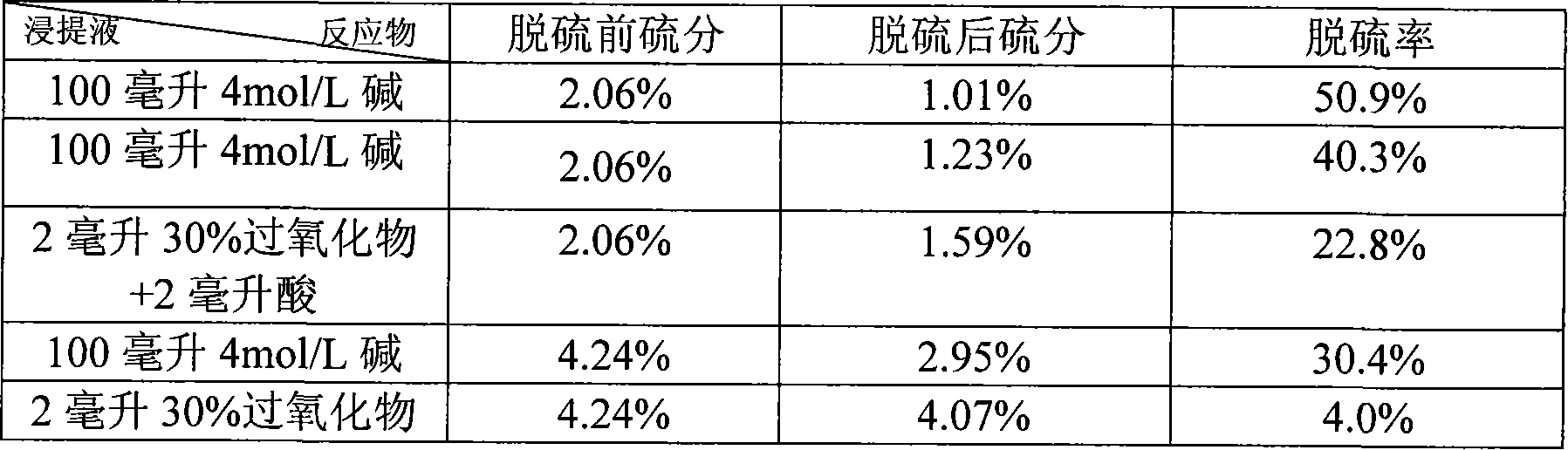

[0026] After pulverizing 40 grams of raw coal (respectively Shandong Guohong coal powder, Shandong Xuecheng Shanjiacun fat coal, live chicken and rabbit coal) (particle size is less than 0.3mm); add to 60 grams of water and stir for 2 minutes to obtain a relatively uniform dispersion system; then Add 100 milliliters of 4 moles per liter of alkali solution (optional sodium hydroxide, potassium hydroxide) and transfer to a 250 milliliter Erlenmeyer flask, put it in a microwave oven for 6 minutes of microwave thermal desulfurization reaction, and carry out microwave radiation catalysis; take it out and use A small amount of water is washed and filtered, and the amount of water added is 20 milliliters each time, and washed until the filtrate pH value is less than 9. The filter cake is soaked with 5 moles per liter of hydrochloric acid for 5 minutes, heated and boiled for 15 minutes, then left to cool; finally filtered and dried. In this example, a microwave oven is used for microw...

Embodiment 2

[0030] Embodiment 2: heating condition experiment

[0031] According to the method described in Example 1, the difference is that one of them is heated by microwave for 6 minutes, and the other two experiments are heated in other ways, and the temperature of the system is kept at 80 and 90 ° C for 24 hours. Other treatment methods and reactions The conditions are the same.

[0032] Comparison of catalytic effects between microwave and other heating methods: (coal sample: fat coal from Shanjia Village, Xuecheng, Shandong)

[0033] means

Embodiment 3

[0034] Embodiment 3: microwave treatment time experiment

[0035] The treatment was carried out according to the method described in Example 1, except that the microwave treatment time was set to 2, 3, 4, 5, 6, 7, and 8 minutes respectively, and other treatment methods and reaction conditions were the same.

[0036] Comparison of microwave time effects: (Coal sample: Fat coal from Shanjia Village, Xuecheng, Shandong)

[0037] time / min

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com