Rapid unhooking safety device for thermal treatment quenching

A technology of safety and hook body, applied in the direction of transportation and packaging, load hanging components, etc., can solve problems such as enterprise loss, hanging in the air, fire, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

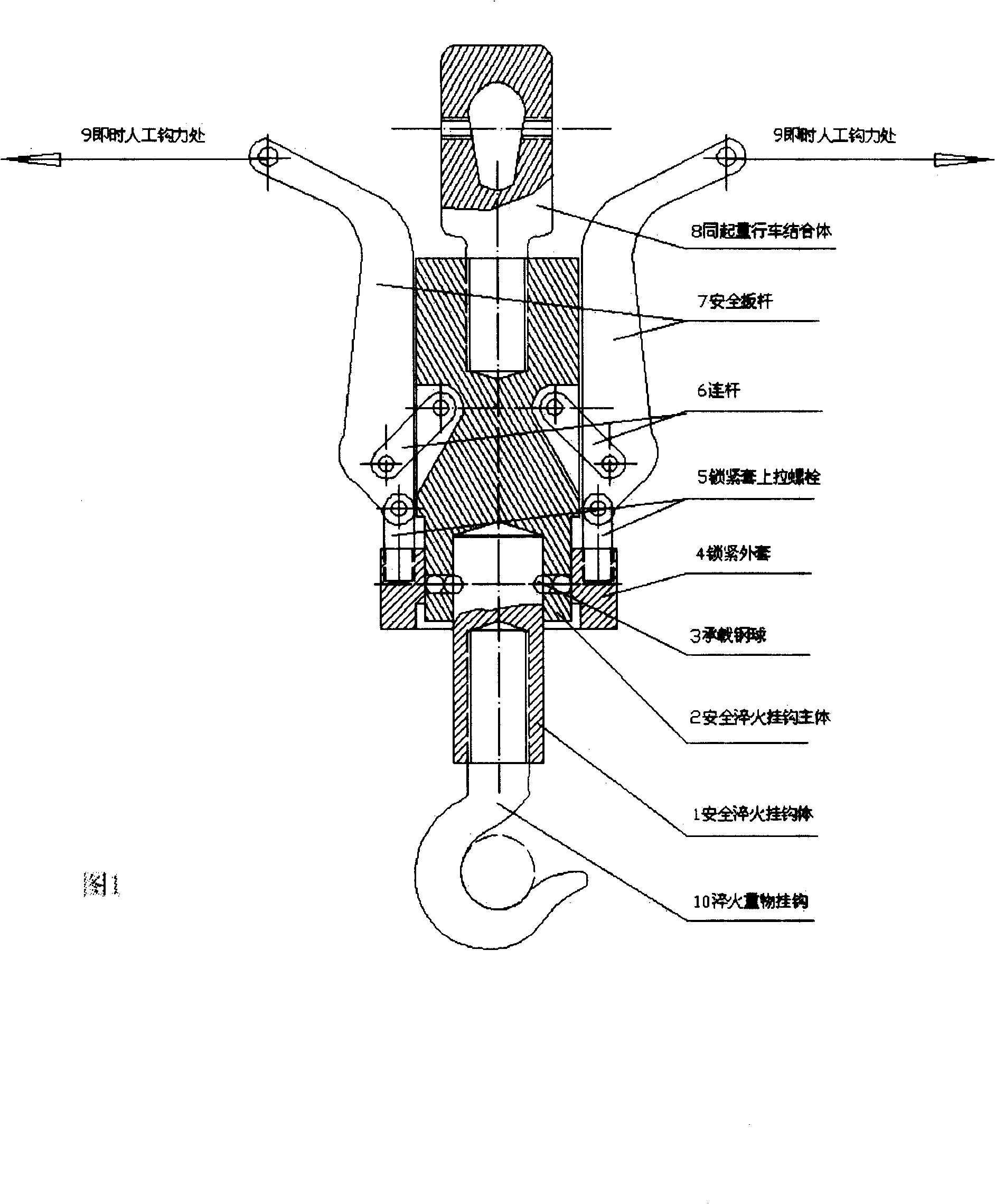

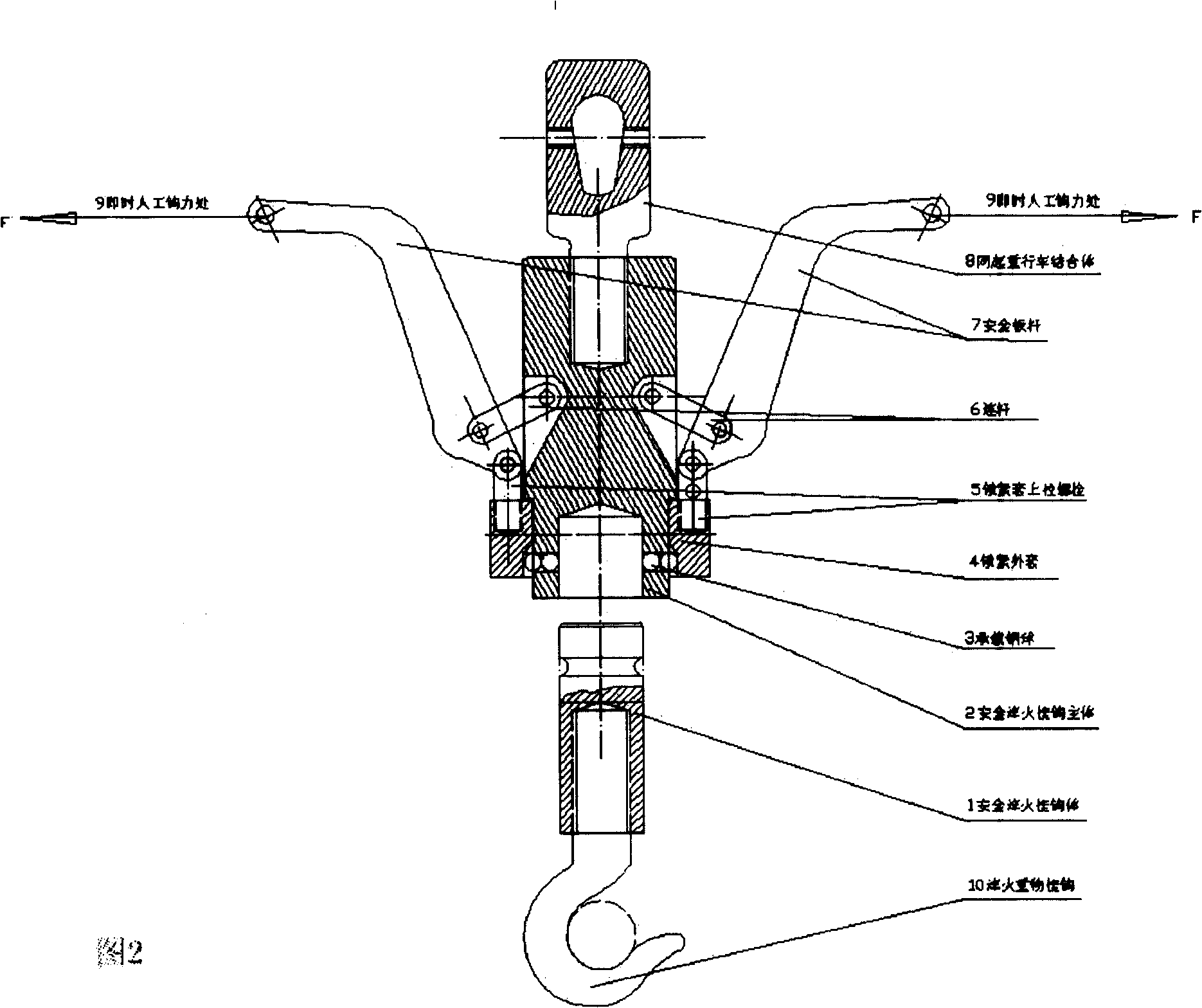

[0008] The present invention is owing to being contained in a kind of fast decoupling safety device between driving hook and quenching workpiece, and its implementation is as follows:

[0009] 1. The "8 combined body with crane and crane" of this device is put on the crane hook and tightened with left and right screws;

[0010] 2. Make two safety iron hooks according to the width of the heat treatment quenching oil pool of the enterprise, and each length is greater than 1 / 2 of the width of the quenching oil pool;

[0011] 3. Once there is a situation, the two workers on duty take the safety iron hook respectively, and at the same time hook the device "instant manual hook force";

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com