Integrated electric voltage detector based on strain effect

A pressure gauge and electronic technology, which is applied in fluid pressure measurement by changing ohmic resistance, weapon accessories, weapon testing, etc., can solve the problems of large volume of electronic pressure gauge, unable to meet the use requirements, and large volume of pressure sensor. Achieve the effect of simple structure, low production cost and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] specific implementation plan

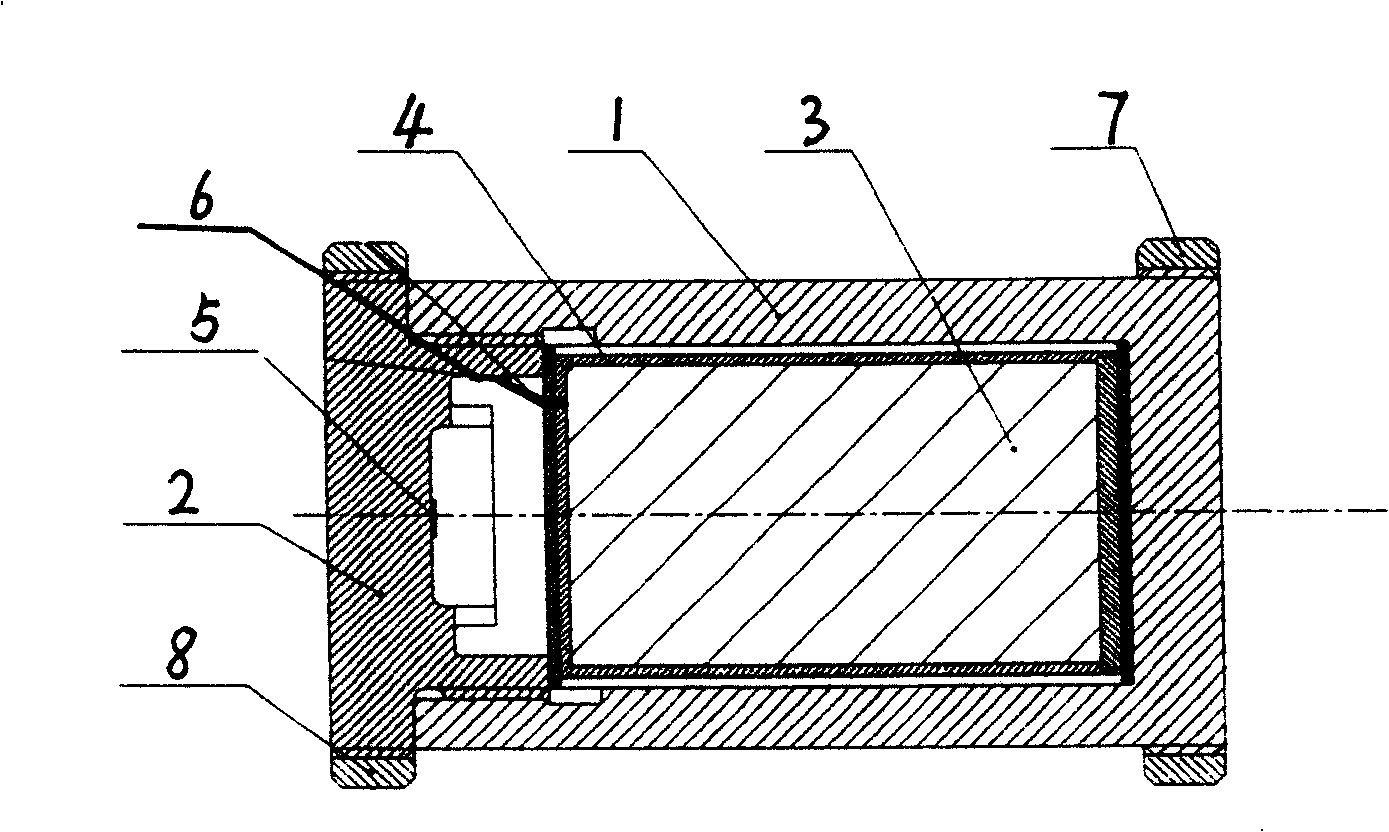

[0023] An integrated electronic pressure gauge based on the strain effect, including a cylindrical shell 1, an end cap 2 made of elastic metal material fixed at the end of the cylindrical shell 1, and a device for placing and measuring The protective inner tube 4 of the circuit 3; the center and side walls of the inner surface of the end cover 2 are fixed with resistance strain gauges 5 and 6 connected to the input end of the measurement circuit 3 for sensitive pressure change and temperature change respectively. The two ends of the cylindrical shell 1 are provided with inherent breech rings 7 and 8 . The elastic metal material adopts martensitic effective steel, and the yield limit stress of this material is: σ s =2000Mpa. In fact, all metal materials are elastic materials, but their elastic ranges are different. For example, some metals undergo plastic deformation at 100Mpa; therefore, the metal materials selected for end caps and shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com