Failure protection discharge valve for pressure vessel

A technology for containers and control valves, applied to pressure vessels, equipment for discharging from pressure vessels, methods for container discharge, etc., which can solve problems such as reducing working pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

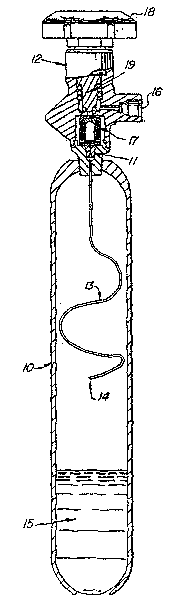

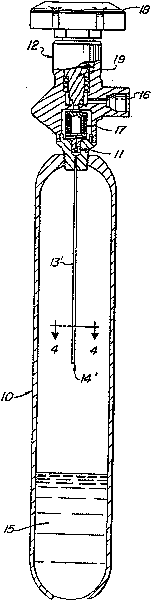

[0029] See attached figure 1 , the present invention looks like a typical delivery device from the outside, and it includes a capacity 500cc gas cylinder 10 with a cylinder overhead valve 12 at the top, and has an outlet 16. The interior or cylinder contains a capillary tube 13 with an inlet 14 which supplies arsine gas to the valve inlet 11. The liquid arsine reservoir 15 located at the bottom of the cylinder 10 will replenish the arsine gas as soon as it leaves the cylinder and maintain the vapor pressure within the cylinder until depleted. Regulator 17 located within valve 12 contains a bellows assembly 28 which automatically controls the discharge of arsine gas from the cylinder. The handle 18 enables manual control of the main valve element 19 .

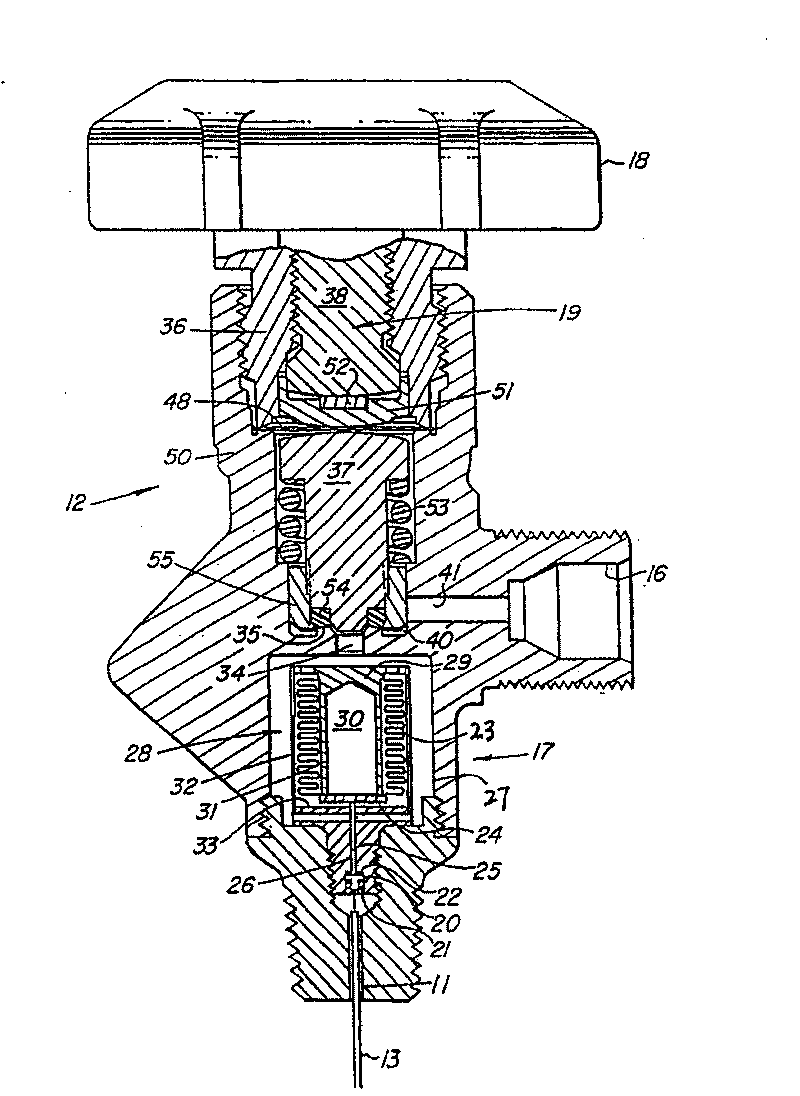

[0030] figure 2 The internal structure of the regulator 17 and the overhead valve 12 is shown in detail. Along the pipeline of the arsine gas exiting the overhead valve 12, the gas first enters the valve inlet 11 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com