Slide way assembly for assembling lengthened nut

An elongated and slideway technology, applied in metal processing, metal processing equipment, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

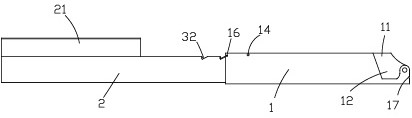

[0032] Such as Figure 1 to Figure 5 as shown,

[0033] A slideway assembly for elongated nut assembly, including a main slideway 1 and an auxiliary slideway 2, the main slideway 1 and the auxiliary slideway 2 are open, and can also be made into a square tube (square hollow tube) , according to the needs, the preferred technical solution of the present invention is an open type, the nut can move along the auxiliary slideway 2, the main slideway 1 and the auxiliary slideway 2 are respectively composed of front and rear side plates and a slide plate, and the two sides of the slide plate are respectively connected to the The side plate is connected, the upper end is an opening, the height of the front and rear side plates is slightly larger than the maximum outer diameter of the nut, the delivery end of the main slideway 1 is provided with a provocation port 12, and the provocation port is located on the front side plate of the main slideway 1, and the nut The screw hole exposes...

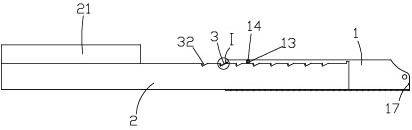

Embodiment 2

[0042] Such as Image 6 As shown, the structure of the slideway assembly for assembling the elongated nut in this embodiment is basically the same as that of the slideway assembly for assembling the elongated nut in Embodiment 1. The difference is that in this embodiment, the guide member 13 consists of The guide strips 15 respectively formed on the two side plates of the main slideway 1 are formed. The top of the auxiliary slideway 2 is slidably matched with the guide strips 15. The auxiliary slideway 2 can slide along the guide strips 15. The side plates of the auxiliary slideway 2 are located on the The other structures of the guide bar 15 and the slide plate of the main slideway 1 are the same as those of the slideway assembly for assembling the elongated nut in the first embodiment.

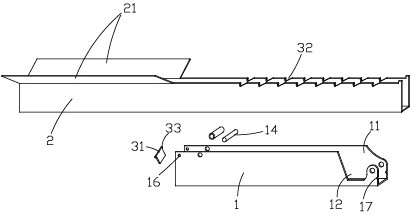

Embodiment 3

[0044] Such as Figure 7 to Figure 9 As shown, in the slideway assembly for elongated nut assembly of this embodiment, connecting rivets 4 are arranged between the side plate of the auxiliary slideway 2 and the side plate of the main slideway 1, and the auxiliary slideway 2 is rotatably arranged on the main slideway. At the interface end of track 1, the auxiliary slideway 2 can be folded and matched with the main slideway 1, and the auxiliary slideway 2 can be switched between the folded position and the open position. When opening, turn the auxiliary slideway 2 to make the auxiliary slideway 2 and the main slideway 1 180° between them is unfolded, so that the auxiliary slideway 2 is in the open position. When the nut is placed, the nut can slide into the main slideway 1, and the auxiliary slideway 2 is turned towards the delivery end of the main slideway 1, so that the auxiliary slideway The track 2 can be folded with the main slideway 1, so that the auxiliary slideway 2 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com