Single planet wheel reversing mechanism

A reversing mechanism and a single planetary technology, applied in the field of automobile transmission, can solve the problems of not having a reversing function and not being able to provide mechanical power in reverse, so as to avoid the occurrence of danger and the inconvenience of operation, and it is easy to automate and work stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

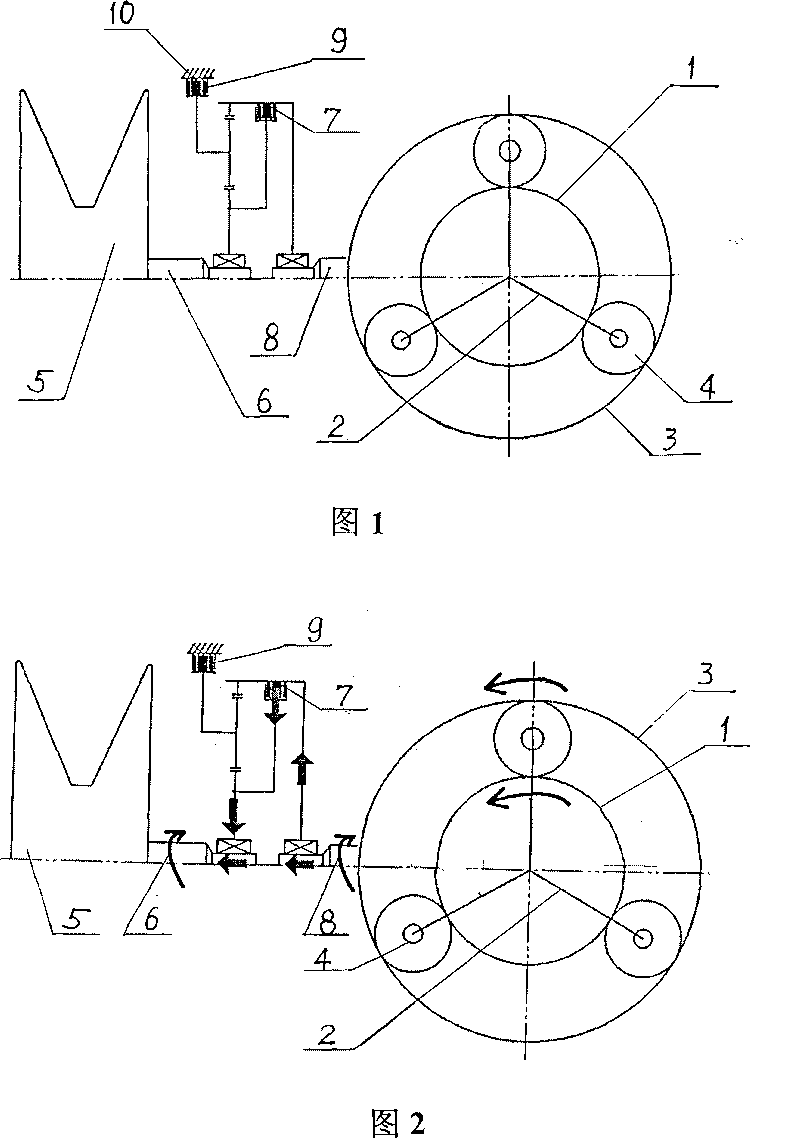

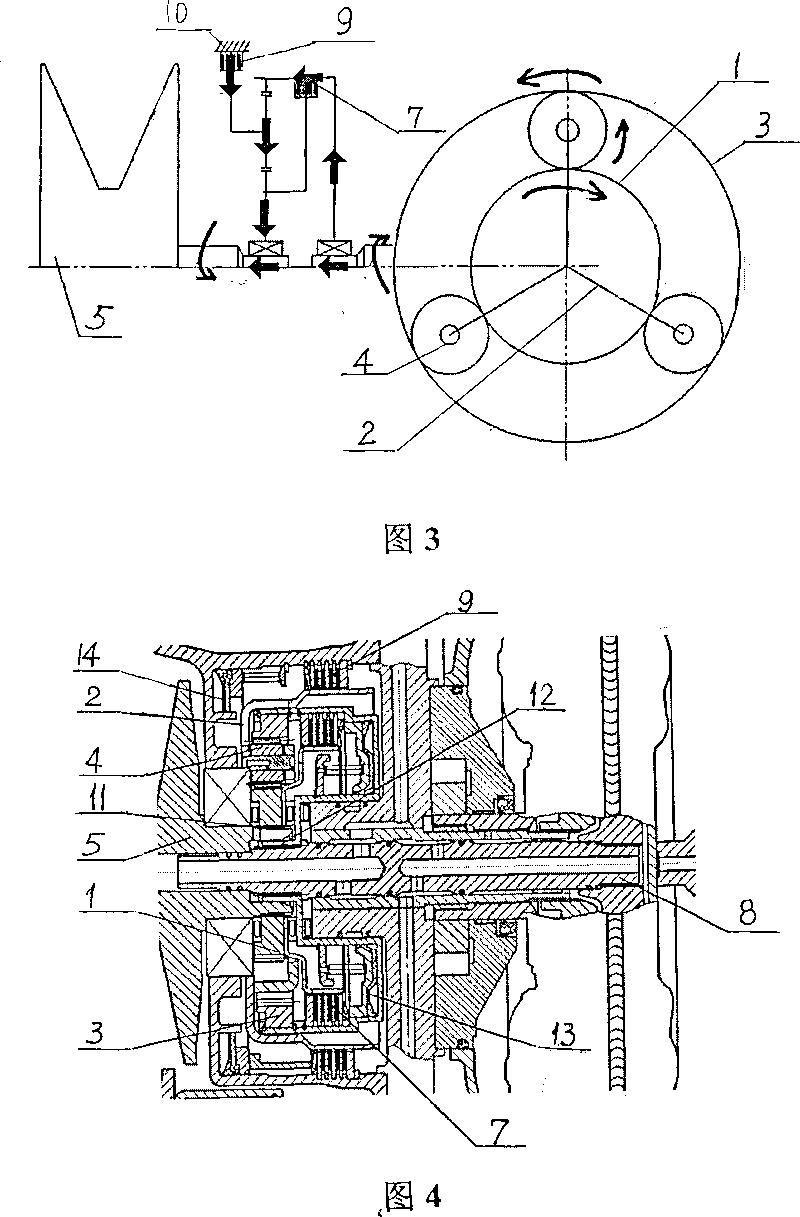

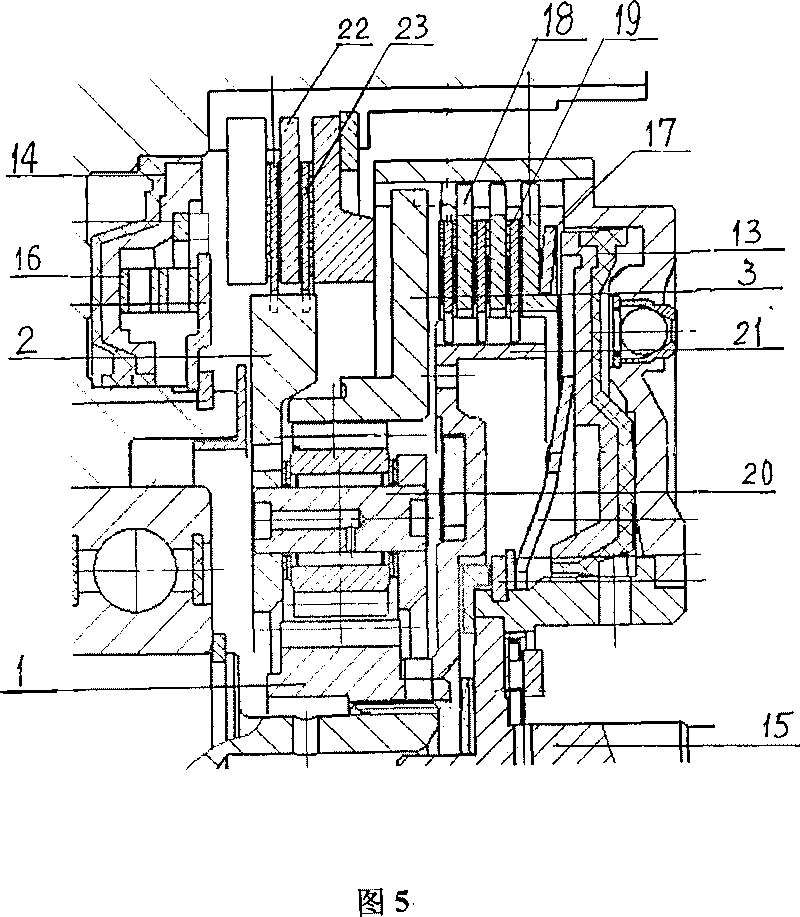

[0016] Referring to the accompanying drawings, the planetary mechanism of the single planetary reversing mechanism of the present invention is composed of a sun gear 1, a planetary carrier 2, a ring gear 3, and three planetary gears 4, and the three planetary gears are evenly distributed on the ring gear 3 On the circumference between the sun gear 1 and the sun gear 1; the sun gear 1 is connected to the driving pulley shaft 5 of the continuously variable automatic transmission through an internal spline, and 6 in the figure is the output shaft, and the sun gear 1 is connected to the internal tooth friction plate of the forward clutch 7, and the forward clutch The outer tooth friction plate of 7 is fixedly connected with the input shaft 8 and the ring gear 3, the planetary carrier 2 is connected with the inner tooth friction plate of the reverse brake 9, and the outer tooth friction plate of the reverse brake 9 is fixed with the continuously variable automatic transmission housin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com