Magnetic driven metering pump

A metering pump, magnetic drive technology, applied in the direction of pump, pump control, pump components, etc., can solve the problems of decreased metering volume, increased working pressure, application limitations, etc., to achieve the effect of reducing dependence and improving metering accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

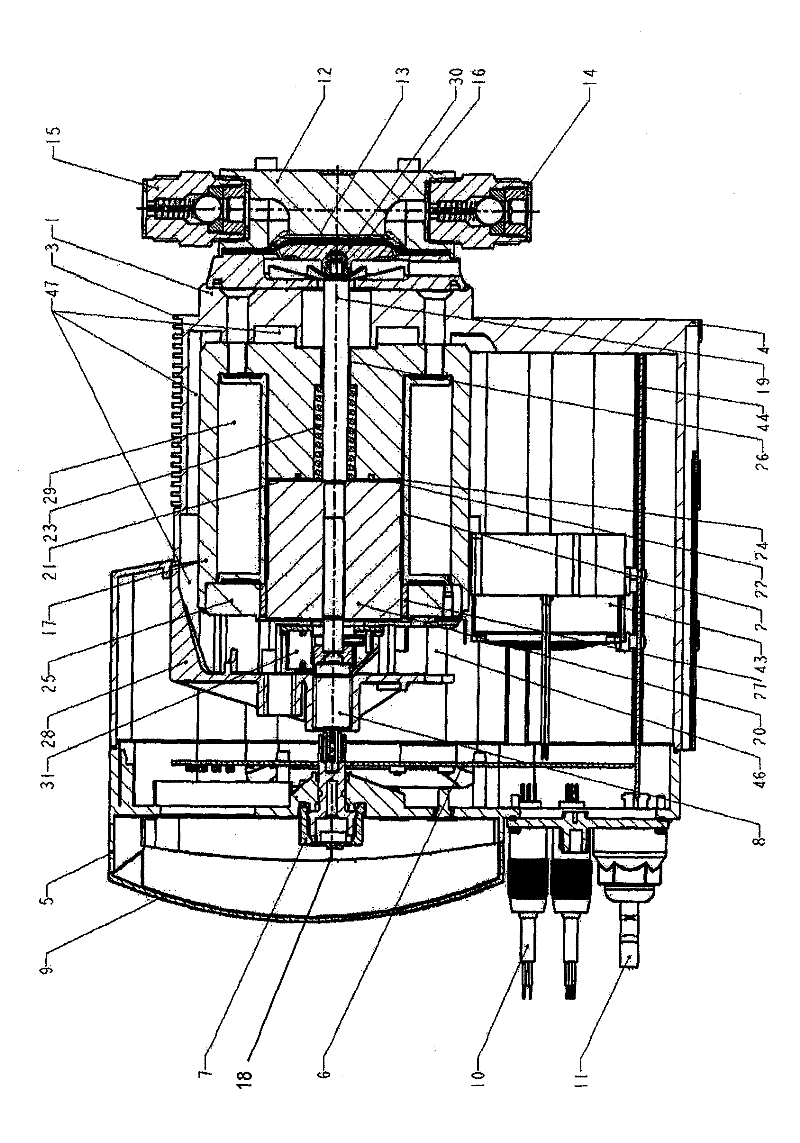

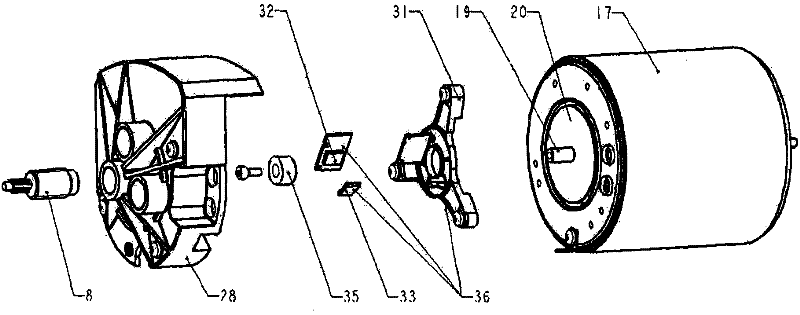

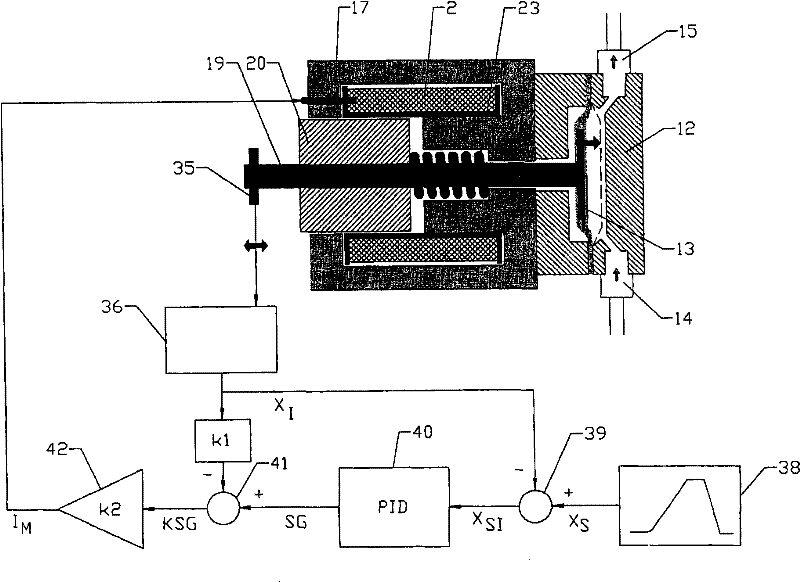

[0066] figure 1A longitudinal section of a magnetically driven metering pump (MD) is shown. On the lower side is the housing 1 of the bottom plate 4 with ribs 3 close to the magnets (upper part) to prevent hot surfaces from being touched. As is known, the upper region of the housing 1 contains a magnetically actuated cover plate 17 . One side of the casing is closed by a casing cover 5 installed and fixed on the casing. At the center of the housing cover 5 and coaxially with the longitudinal axis 18 of the substantially rotationally symmetrical magnet, a manually adjustable correction member 7 is incorporated into the housing cover for adjustment to limit the axial movement and Stroke correction pin 8 for diaphragm pump stroke. The correction part 7 and other operating elements are protected by a cover 9 . Below the cover 9 is an interface for a control line 10 or a mains line 11 . On the side opposite the housing is a metering head 12 , in which a membrane 13 , for examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com