Pre-process production method and product line for container sheet material

A production method and pretreatment technology, applied in the field of container plate production technology, to achieve the effects of reduced floor space, increased production efficiency, and reduced labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

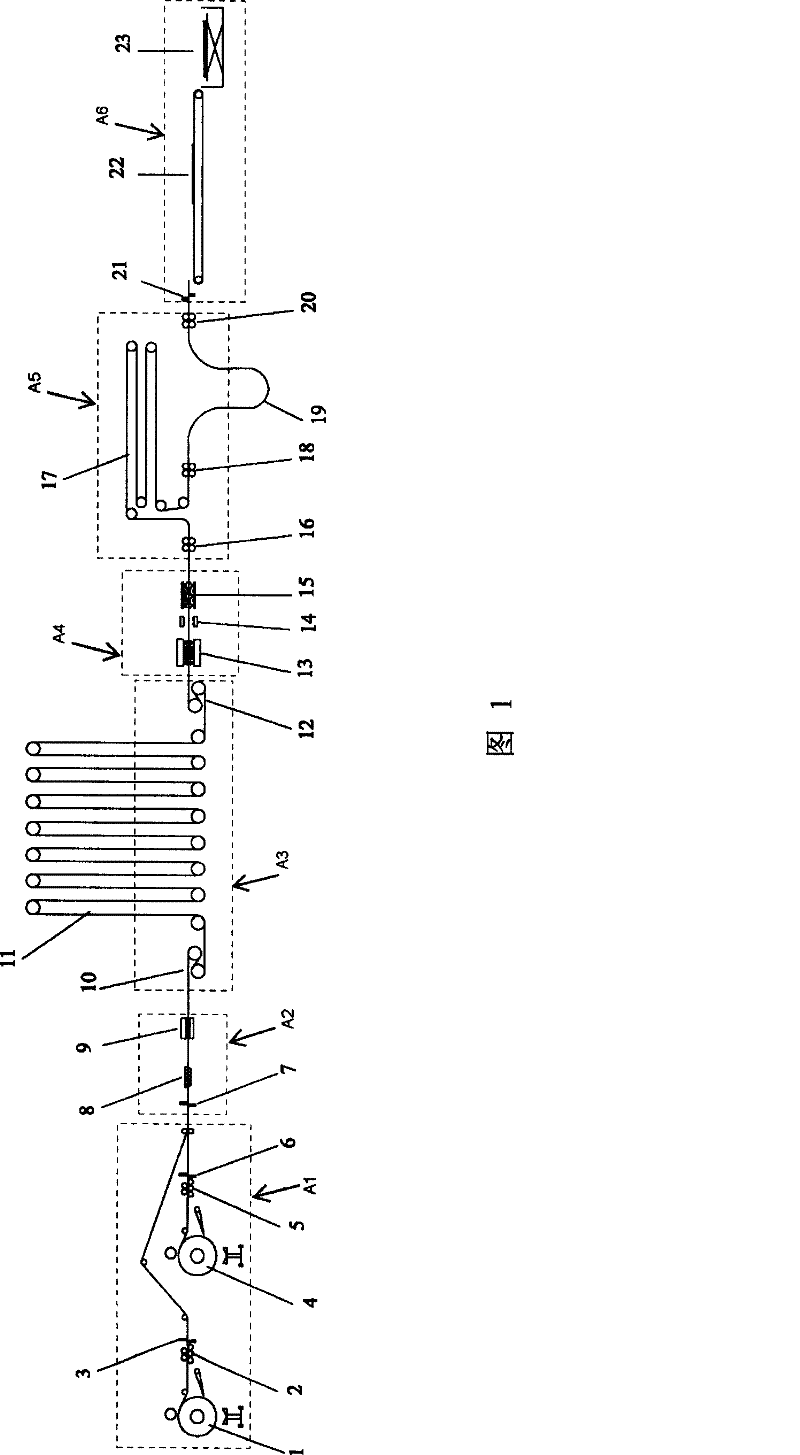

[0050] figure 1 It is a schematic plan layout diagram of the first embodiment of the container plate pretreatment production line of the present invention. Such as figure 1 As shown, the production line mainly includes the following production steps:

[0051] Uncoiling A1: Use uncoiling equipment to uncoil the required coil material such as steel coil. figure 1 The illustrated embodiment uses double uncoiling equipment 1 and 4, and the two uncoiling equipment are used alternately to ensure continuous production of the production line. In this step A1, the continuous strip material drawn from the uncoiling equipment also undergoes levelling, descaling and cutting head operations. Such as figure 1 As shown, the strip drawn out by the uncoiling device 1 is leveled by the leveling device 2 , and the head of the strip is cut off by the shearing device 3 . Similarly, the strip material drawn from the uncoiling device 4 is leveled by the leveling device 5 , and then the stri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com