Method for producing guiding wheel

A production method and technology of guide wheels, which are applied in the directions of tracked vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of wear, waste of precious time when replacing the guide wheels, wear through and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Referring to Fig. 1 to Fig. 5, the embodiment discloses a production method of a guide wheel, comprising the following steps:

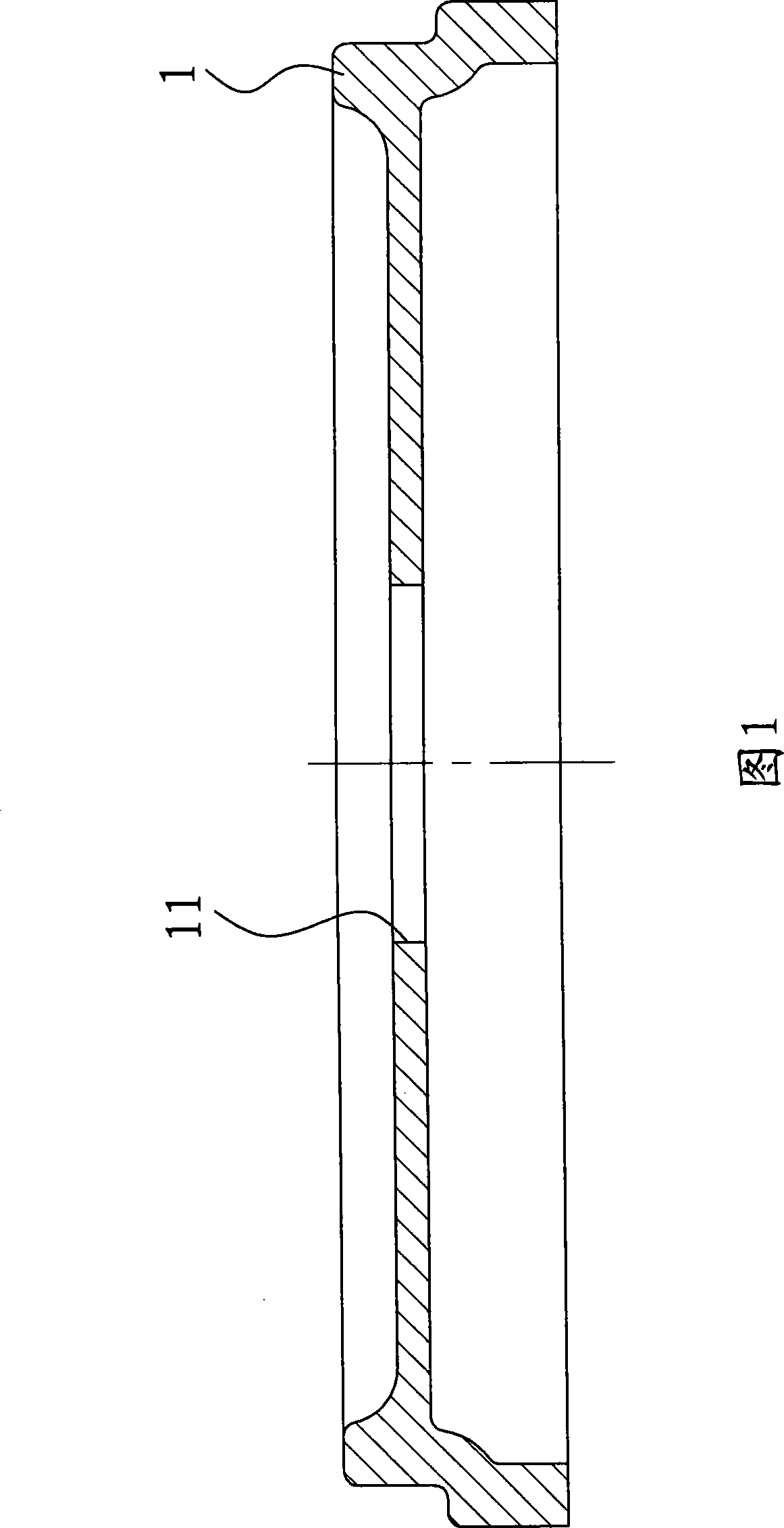

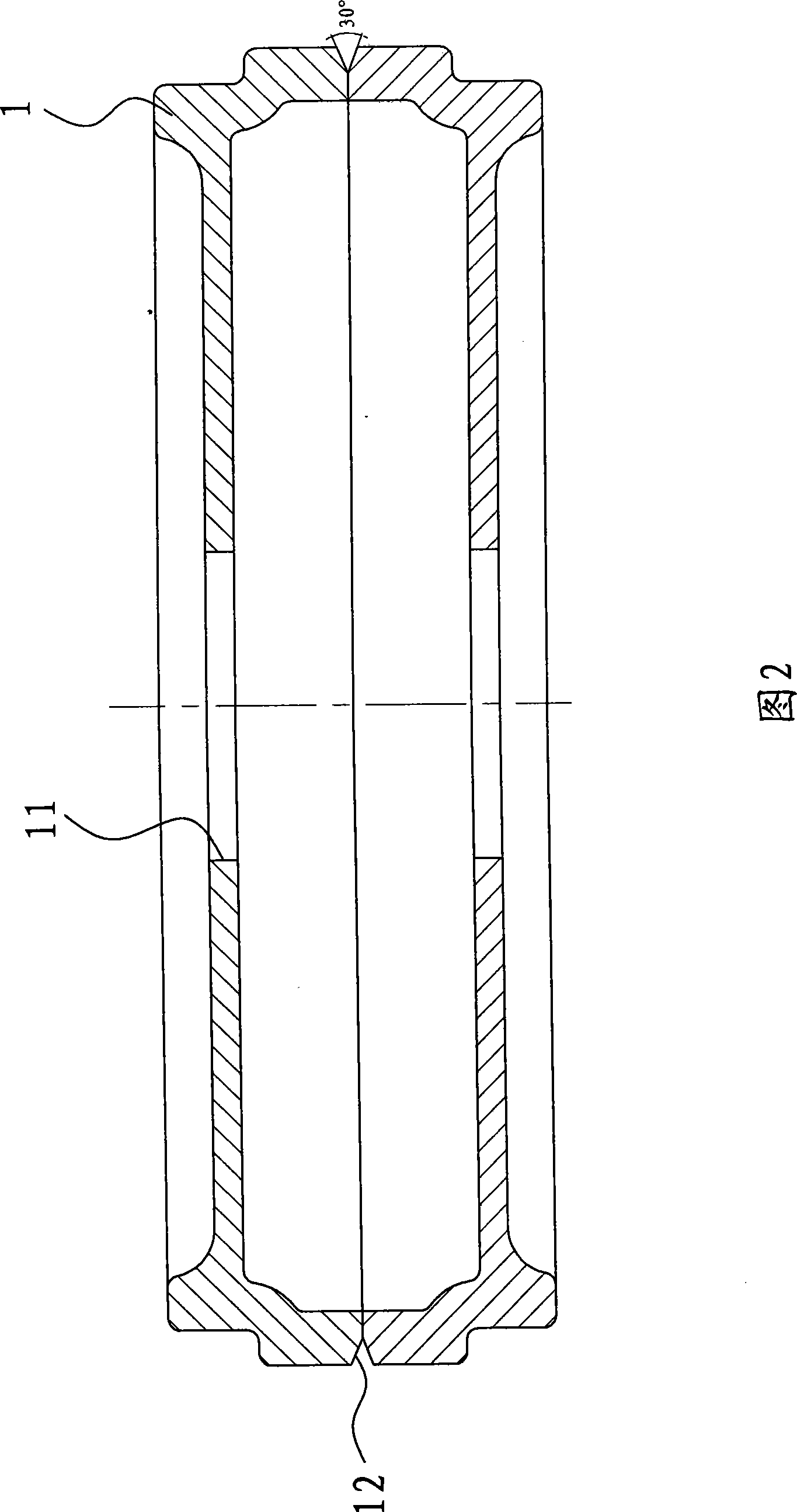

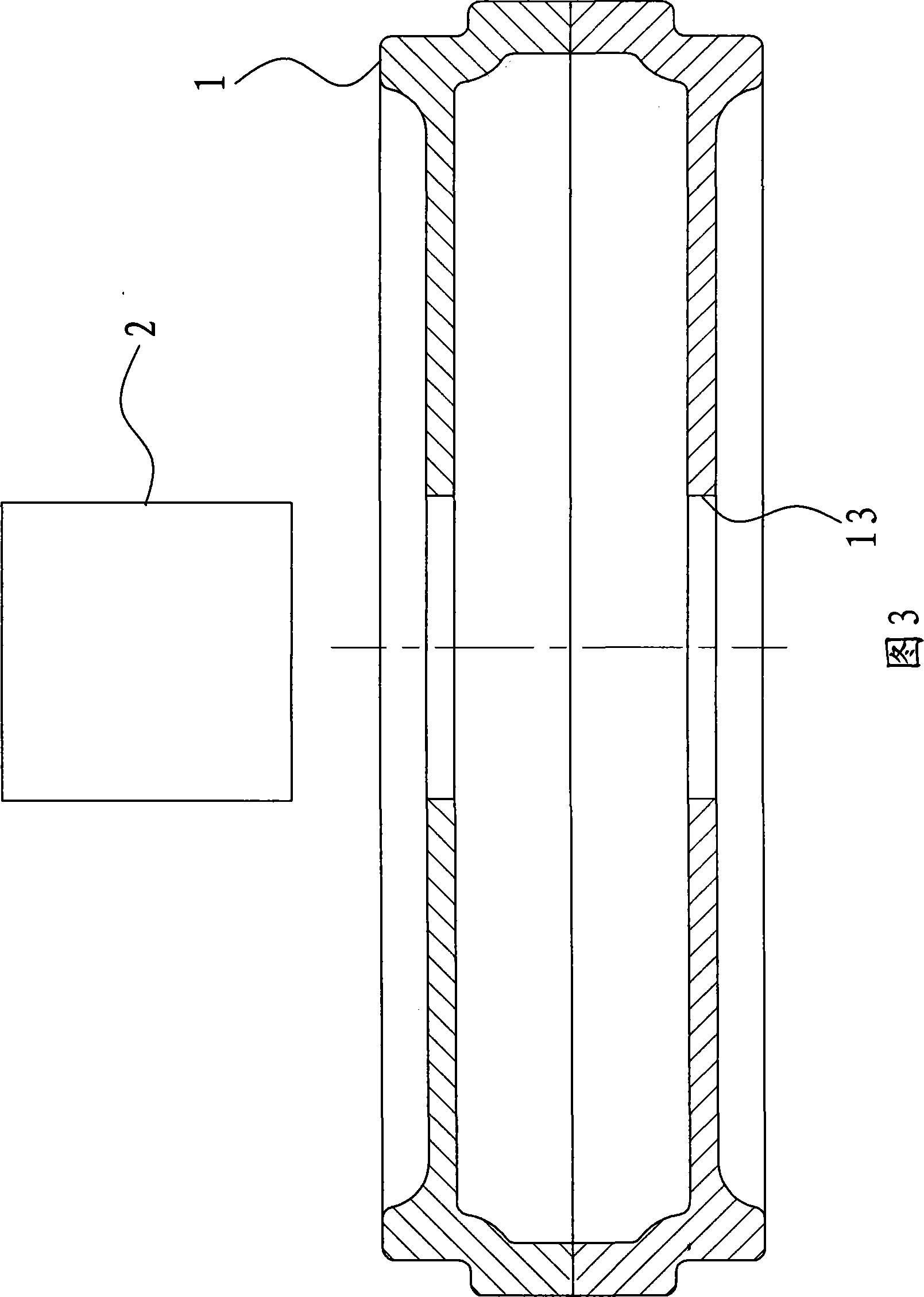

[0025] 1), material preparation: cut a quantitative 40Mn2 round steel billet and place it in a heating furnace to heat it to about 1200°C, then place it on a molding die of a 6000-ton friction press for forging to obtain the side plate 1, and then place it on the side plate 1. A shaft hole 11 is punched out in the radial middle part of the disk 1, and the mold cavity of the forming mold corresponds to the shape of one side of the axial direction of the guide wheel. In other words, the known guide wheel is cut in half along the axial direction, and the described The mold cavity formed by the male mold and the female mold of the forming mold just corresponds to the half guide wheel after cutting, and the shaft hole 11 is punched in the radial middle of the side plate 1 for the convenience of subsequent steps, not for an essential process step;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com