Optimizing method of spray coating robot spray gun track on complex curved surface

A technology of spraying robots and complex curved surfaces, which is applied in the directions of manipulators, spraying devices, manufacturing tools, etc., can solve the problems of material consumption, reduced spraying efficiency, time-consuming and other problems, and achieve the effect of ensuring spraying quality, improving work efficiency and saving paint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

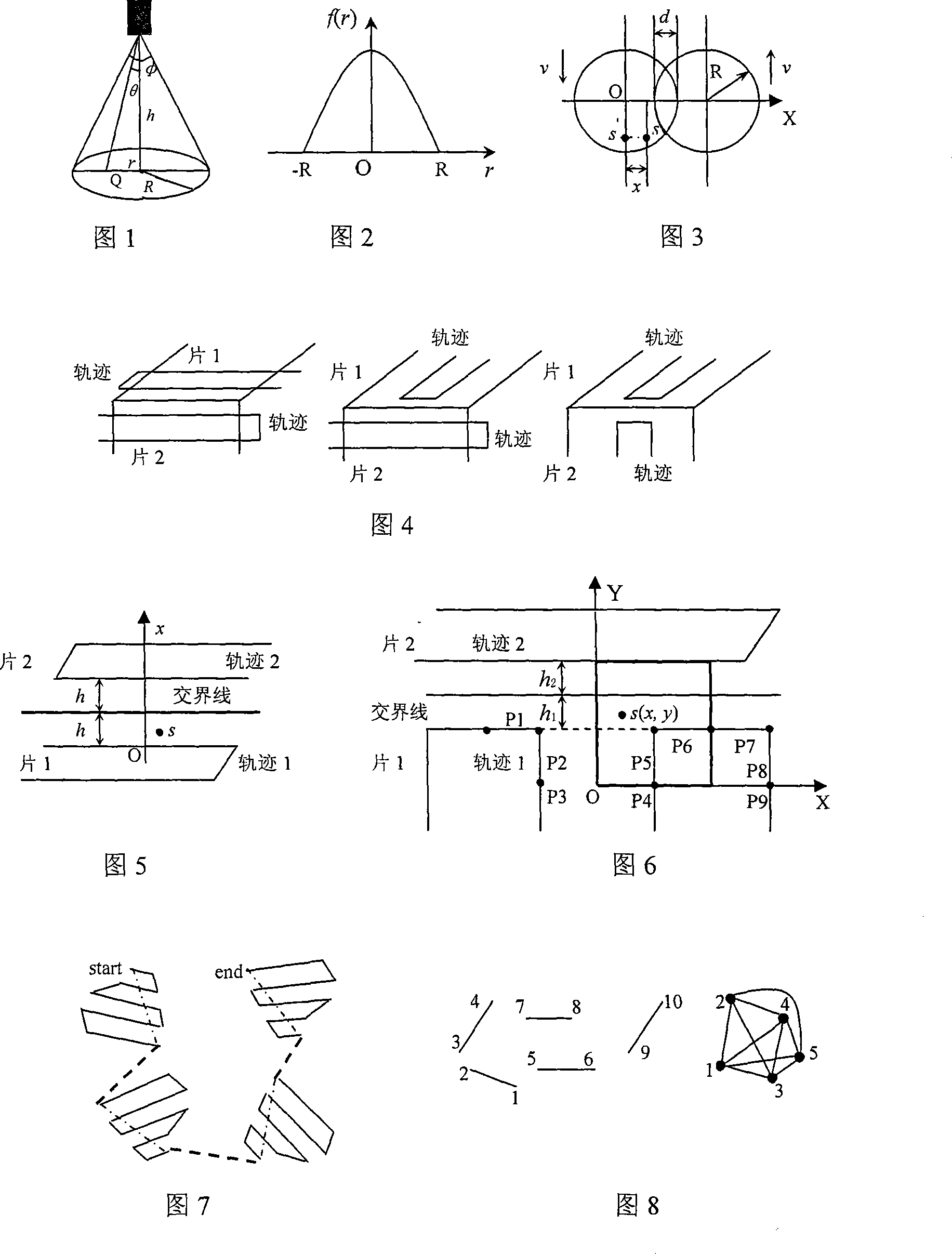

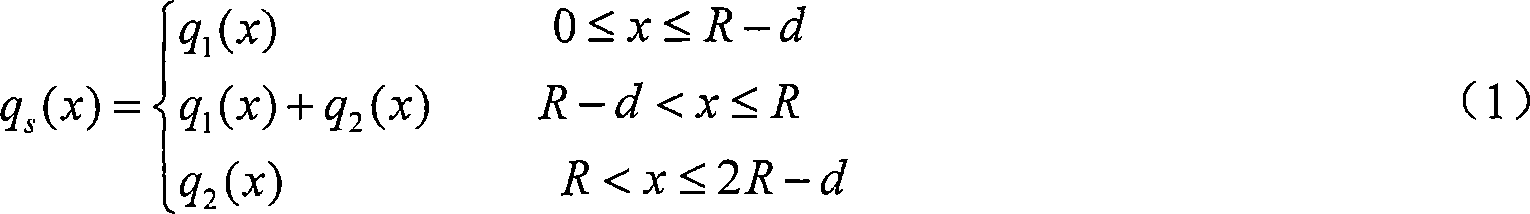

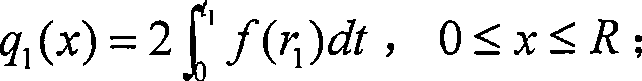

[0021] The method of the present invention is: first slice the complex curved surface, and approximately regard each slice as a plane, and use the spray gun trajectory optimization method on the plane to design the trajectory on each slice; , discussing the optimization of the spray gun trajectory at the junction according to the situation, using the method of segmenting the spray gun trajectory to optimize the trajectory of the junction; using the improved genetic algorithm to optimize the combination of the spray gun trajectory on each piece, and realizing the optimization of the spray gun trajectory on large-area complex surfaces .

[0022] As shown in Figures 1 to 3, in order to improve the computing efficiency of the computer, the present invention first designs a simple coating accumulation model by using the test method. After the curved surface is sliced, the variance of the coating thickness of discrete points on the curved surface and the ideal coating thickness is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com