Apparatus to concentrate a fluid and a multiple chamber pump

A differential piston, concentrating device technology, applied in piston pump, liquid variable capacity machinery, pump and other directions, can solve the problems of pulsation, power loss, increase in structure size of differential piston pump, etc. Noise or vibration, little effect of wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

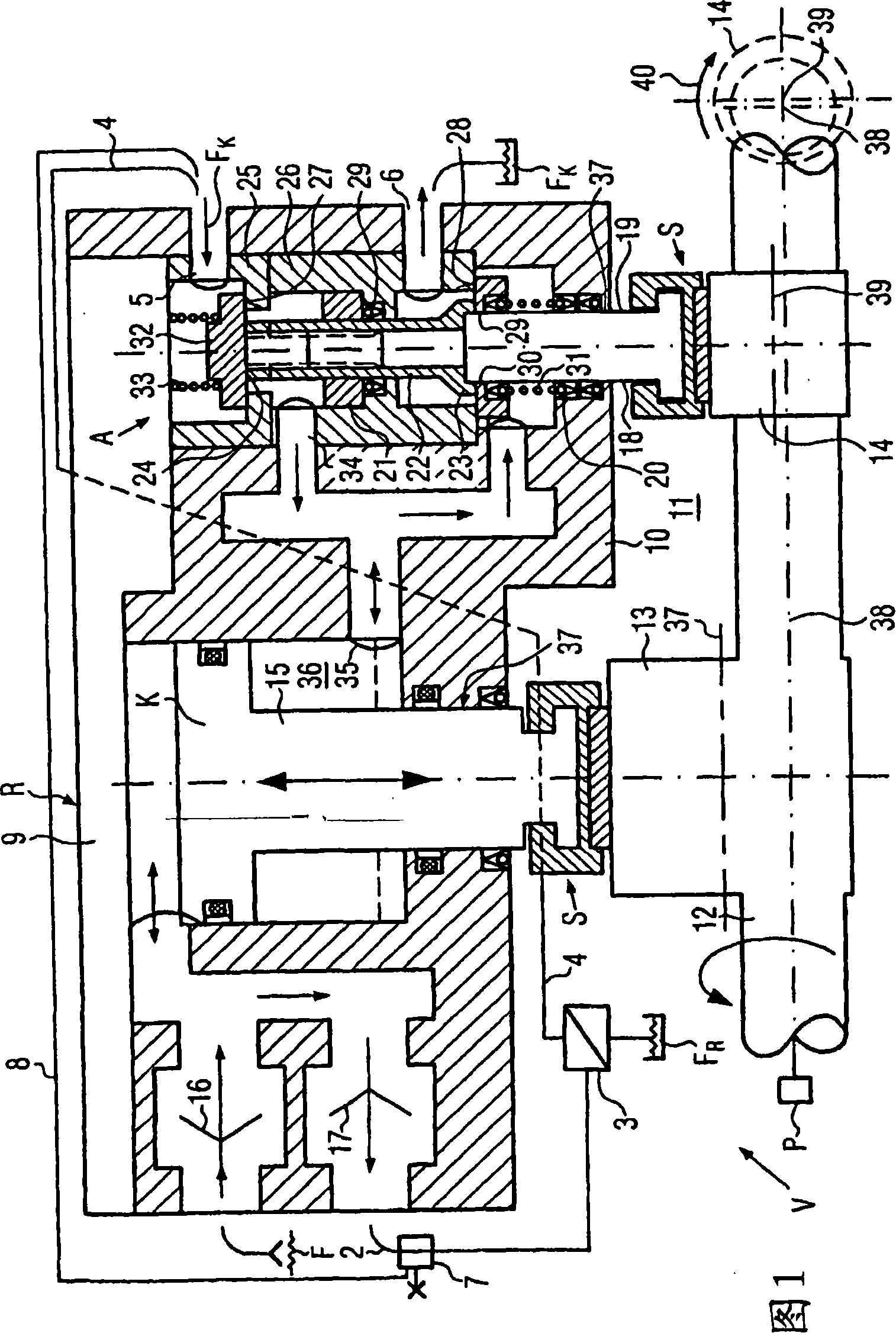

[0038] Figure 1 is used, for example, to form a pure liquid F at the same time R concentrating liquid F into a concentrate or concentrate F in case of K The device V can be a seawater desalination device working on the principle of reverse osmosis, or a device for concentrating fruit juice, etc. In principle, it is provided in the installation V that the liquid F is conveyed by means of a radial piston pump R and is brought under pressure, and is guided through a concentrating device 3 from which a concentrated liquid F with a significant residual pressure is produced K , and the pure liquid F R There is essentially no pressure and it can be collected, for example, as pure desalinated water. Concentrate F with significant residual pressure K Used in the radial piston pump R, the contained energy is used to directly support the conveying liquid F, so that the radial piston pump R can be operated only by consuming less primary energy (such as current or the power of the motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com