DC high current ice fusion device with static dynamic no-power compensation function

A high-current, static technology, applied in reactive power compensation, output power conversion device, reactive power adjustment/elimination/compensation, etc., to achieve the effect of reasonable structure, simple switching operation, and improved equipment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

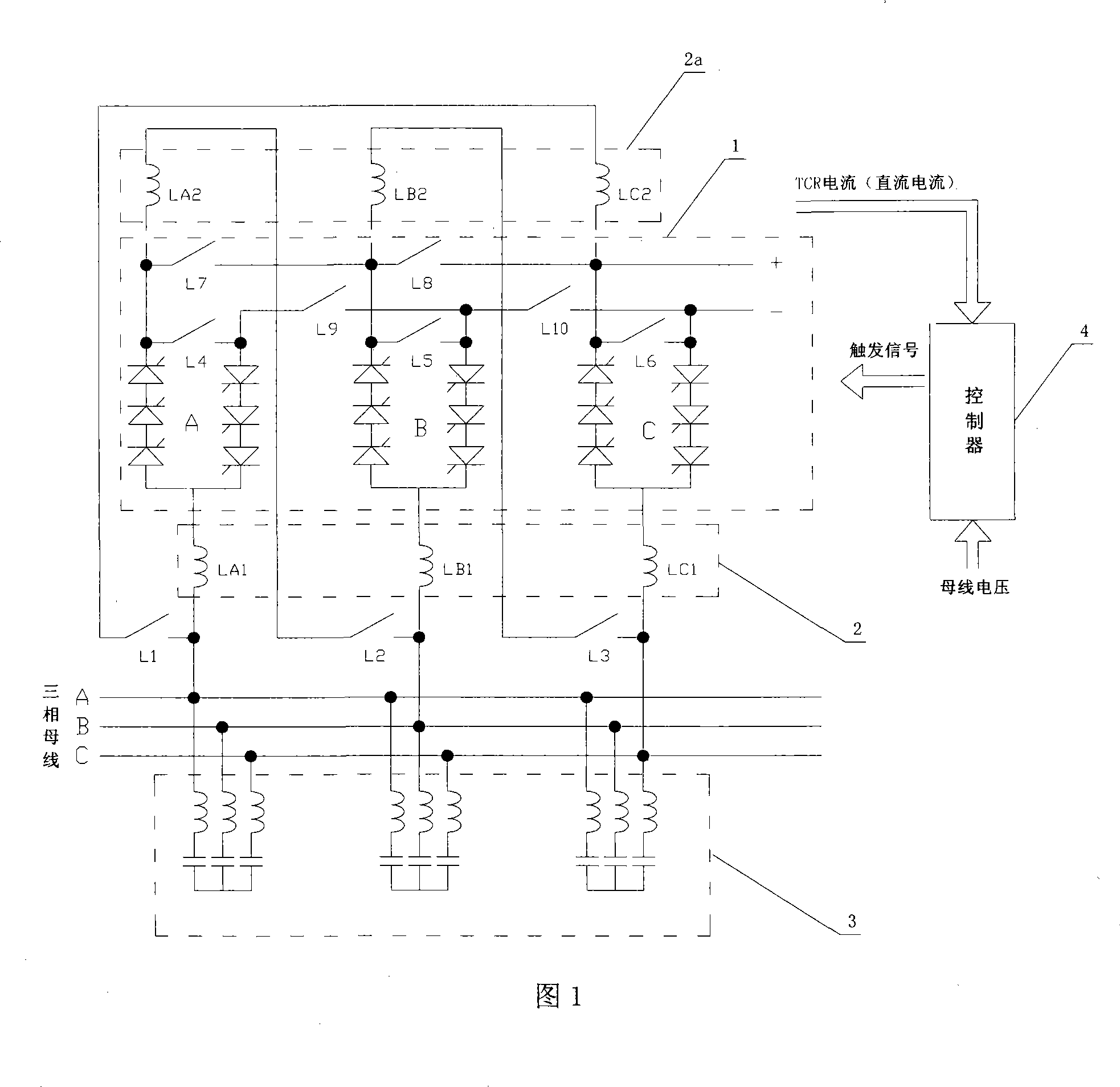

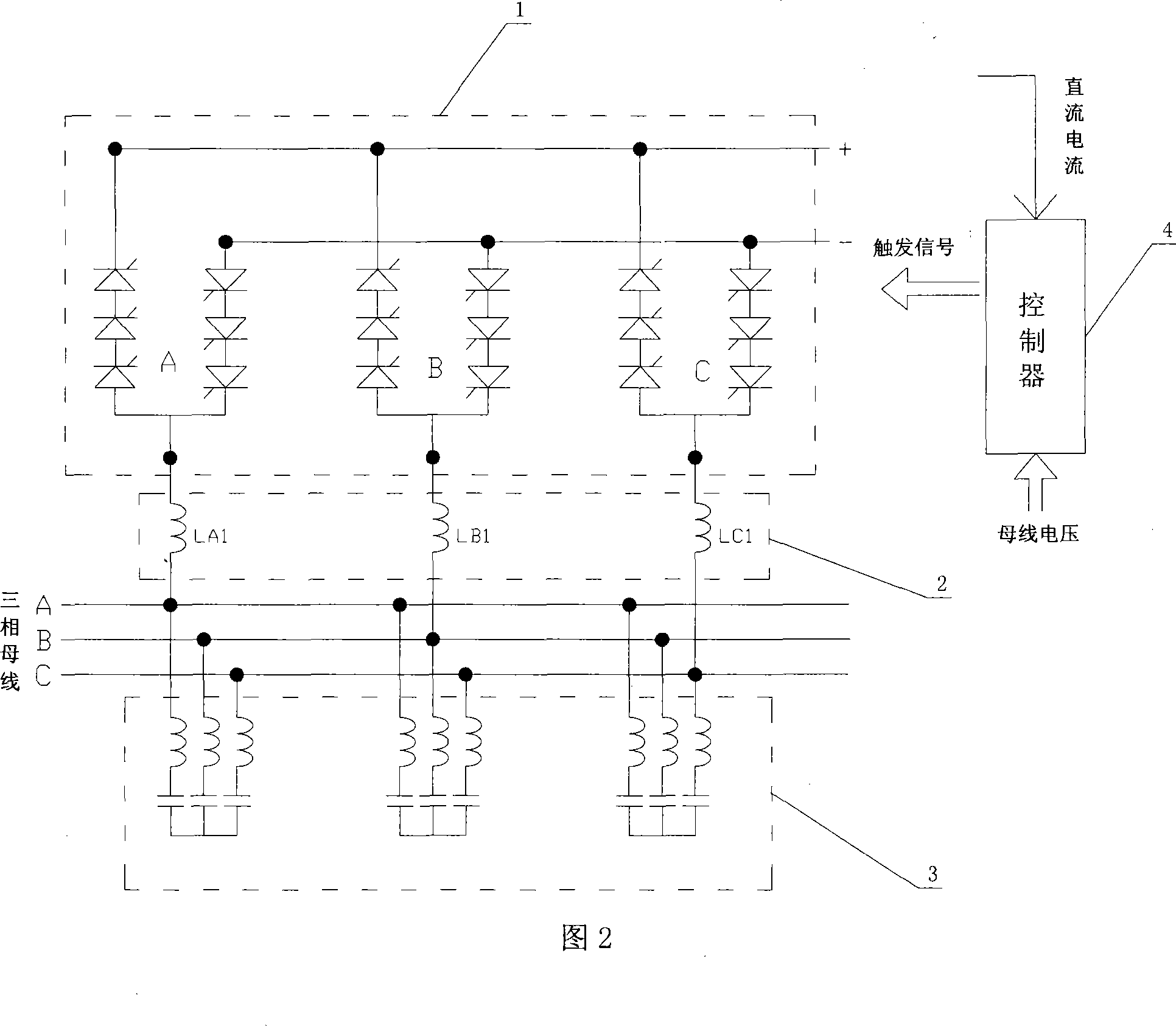

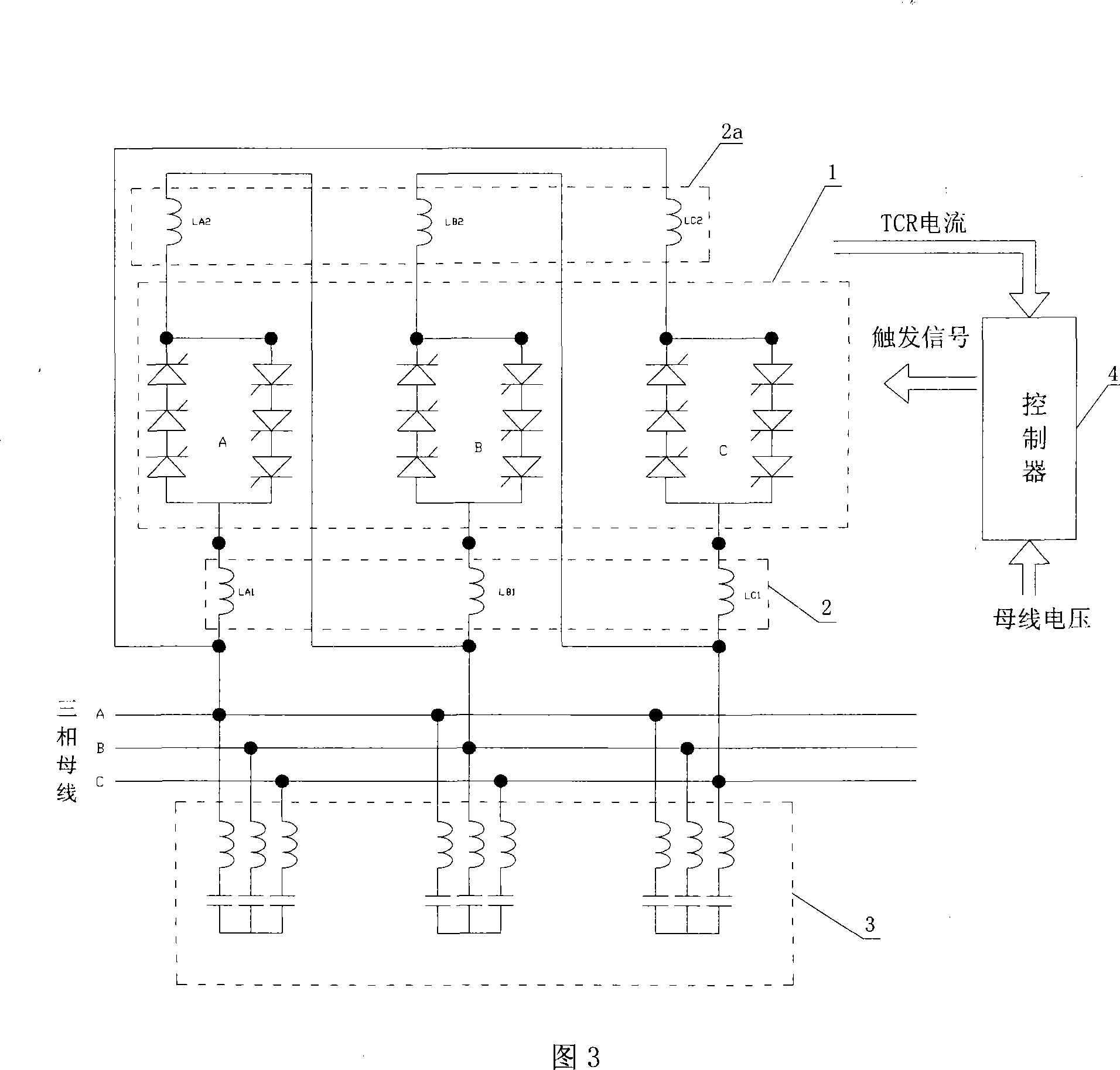

[0020] As shown in Figure 1, the DC high-current ice melting device with static dynamic reactive power compensation function, the main body of each phase of the three-phase high-voltage high-current thyristor valve 1 is a series of thyristors, and each phase of the thyristor valve is external There are three electrical connection terminals, namely the positive electrode, the negative electrode, and the middle point. The type and quantity of the thyristors connected in series between the middle point and the positive electrode and the negative electrode are the same. As shown in Figure 4, the number of thyristors is determined by the voltage and the system voltage. The rated voltage of the thyristor used is determined. The three-phase AC reactor 2 is composed of an A-phase AC reactor LA1, a B-phase AC reactor LB1, and a C-phase AC reactor LC1. The three-phase AC reactor 2a is composed of an A-phase AC reactor LA2, a B-phase AC reactor LB2, and a C-phase AC reactor LC2. The three-ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com