Method of producing solar modules by the roller laminate process

A technology for solar cells and modules, applied in the fields of electrical components, chemical instruments and methods, lamination, etc., can solve the problem of not being able to sufficiently prepare composites with thin-layer solar cell modules on an industrial scale by itself.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

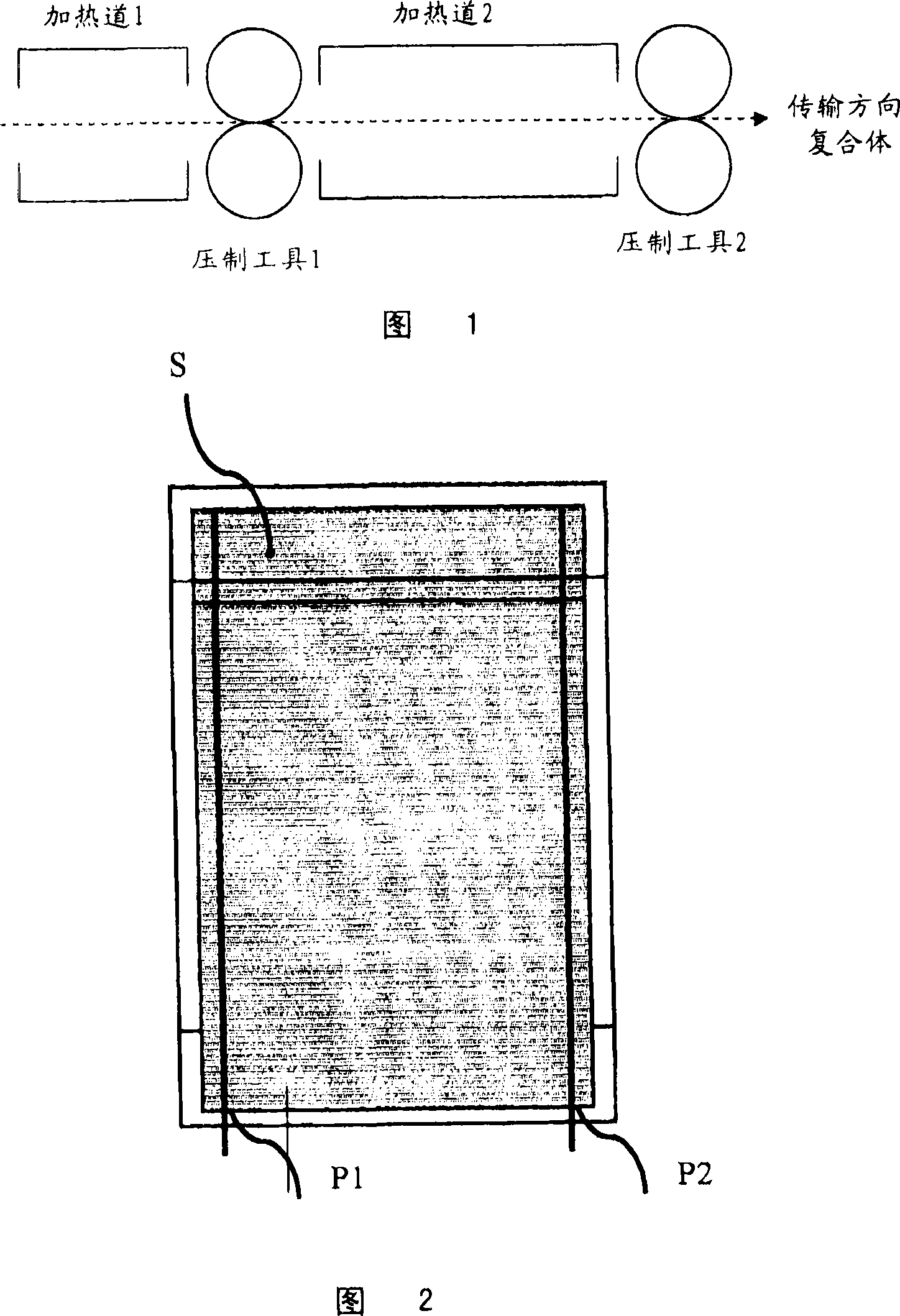

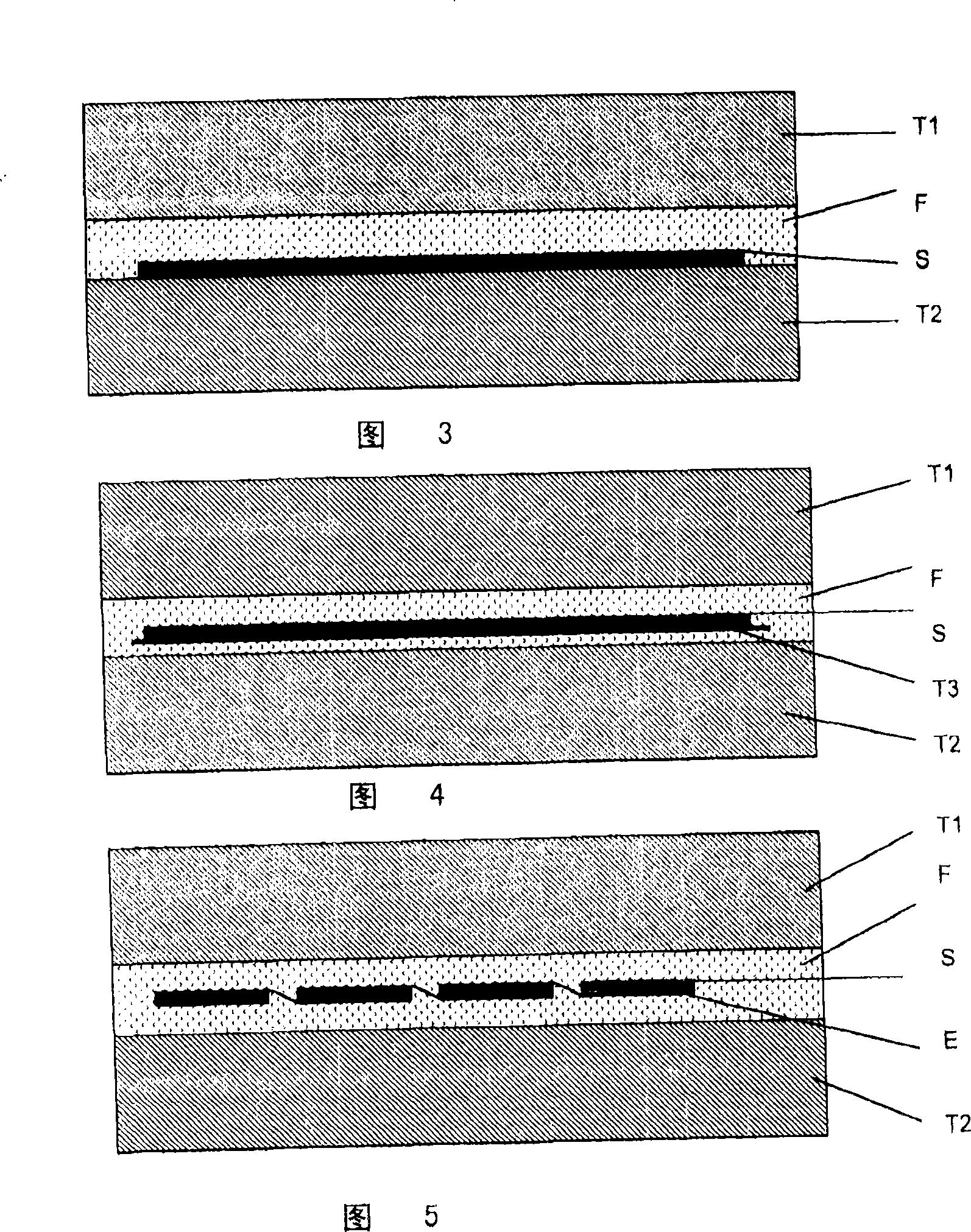

[0044] Thin layers were pressed at a temperature of 90 °C (measured after the last pressing tool) and a linear pressure of 35 N / mm each at a feed rate of 3 m / min in the apparatus shown in Figure 1 Module, the thin-layer module has dimensions of 30 cm long x 20 cm wide and a glass thickness of 3.2 mm, and also has two conductive strips with a longitudinal distance of 20 mm from the edge, a width of 2 mm, and a thickness of about 250 μm. The running direction of the complex is chosen so that the outlet of the conductive channel from the module is at the rear and pressed last. As a softener-containing polyvinyl acetal film, roughness R Z Membrane of the Trosifol HR 100 type (Kuraray Europe GmbH) of about 100 μm.

[0045] The line pressure of the pressing tool is to be reduced to the dead weight of the upper roll over the first 10 mm and the last 30 mm of the ply.

[0046] A slightly cloudy, bubble-free laminate was obtained.

[0047] This turbidity can be completely eliminated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com