Film carrier foamless oxygen supply biological film reactor and organic waste water treatment method

A biofilm reactor and biofilm technology, which is applied in the field of wastewater treatment, membrane carrier non-bubble oxygen supply biofilm reactor and organic wastewater treatment, can solve the problems that MABR has not formed a mature process mode, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Treatment of Wastewater from Nylon Synthetic Industry

[0018] The wastewater composition: COD Cr 2200mg / L, pH 7.8, suspended solids 160mg / L, water temperature 30°C.

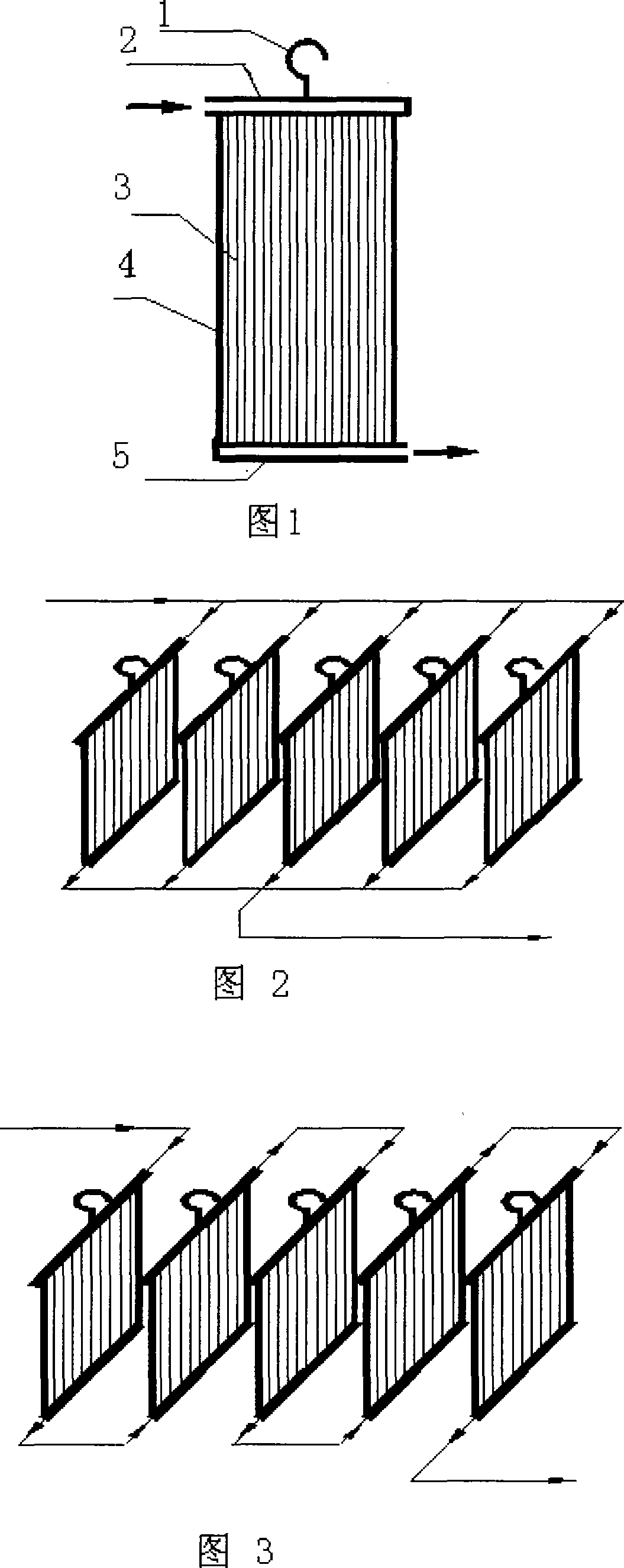

[0019] The process of treating the waste water with the membrane carrier of the present invention is as follows: the curtain-type hollow fiber membrane module made of polyamide dense surface composite polyethersulfone porous hollow fiber membrane is placed in the waste water pool, and the curtain The hollow fiber membrane module has a width of 3 meters and a height of 1.5 meters. Each module has two layers of hollow fiber membranes permeable to oxygen. As shown in Figure 2, there are 5 curtain hollow fiber membrane modules arranged in parallel. The wastewater is introduced into the wastewater tank, and then the activated sludge capable of treating nylon is inoculated into the wastewater tank to cultivate the biofilm. The cultivation conditions are as follows: the air compressed by the air compressor is i...

Embodiment 2

[0021] Treatment of Domestic Wastewater

[0022] The composition of domestic wastewater: COD Cr 400-500mg / L, total nitrogen about 80mg / L, pH about 7.2, suspended solids 120mg / L, water temperature 20°C;

[0023] The curtain-type hollow fiber membrane module made of poly-4-methyl-1-pentene dense cortex asymmetric porous hollow fiber membrane shown in Figure 3 is placed in the waste water tank, and the width of the curtain-type hollow fiber membrane module is 2 meters , a height of 1 meter, each module has 3 layers of oxygen-permeable hollow fiber membranes, to treat the above wastewater, the process is as follows:

[0024] Biofilm cultivation process: introduce the domestic wastewater into the wastewater tank, inoculate the activated sludge capable of treating the domestic wastewater directly into the wastewater tank, adjust the air inlet pressure to 0.2MPa, and the wastewater flows at a flow rate of 0.1m / h After 25 days of cultivation, a 300 micron thick biofilm was attached ...

Embodiment 3

[0027] Treatment of wastewater containing toluene

[0028] The wastewater composition: COD Cr 4000mg / L, pH 8.1, suspended solids 230mg / L, water temperature 18°C

[0029] The curtain-type hollow fiber membrane module made of polyamide dense surface composite polyethersulfone porous hollow fiber membrane shown in Figure 2 is placed in the wastewater reaction tank. The curtain-type hollow fiber membrane module has a width of 3 meters and a length of 1.5 meters. There are 5 layers of oxygen-permeable hollow fiber membranes on the module to treat the above wastewater, the process is as follows:

[0030] Biofilm cultivation process: introduce wastewater into the wastewater tank, inoculate the special microorganisms capable of treating the toluene-containing wastewater into the wastewater reaction tank, adjust the air inlet pressure to 0.2MPa, and the wastewater flows in the wastewater tank at a speed of 0.2m / h , after 13 days of cultivation, a 100-micron-thick biofilm was attached...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com