Plastic winding off spindle material-rolling method and device

A technology for coiling shafts and plastics, which is applied in the field of coiling materials and devices for coiling shafts of plastic coilers, can solve problems such as poor coiling quality, uneven material edges, and crooked coils, and achieve economic benefits and guarantee The effect of flatness and product quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

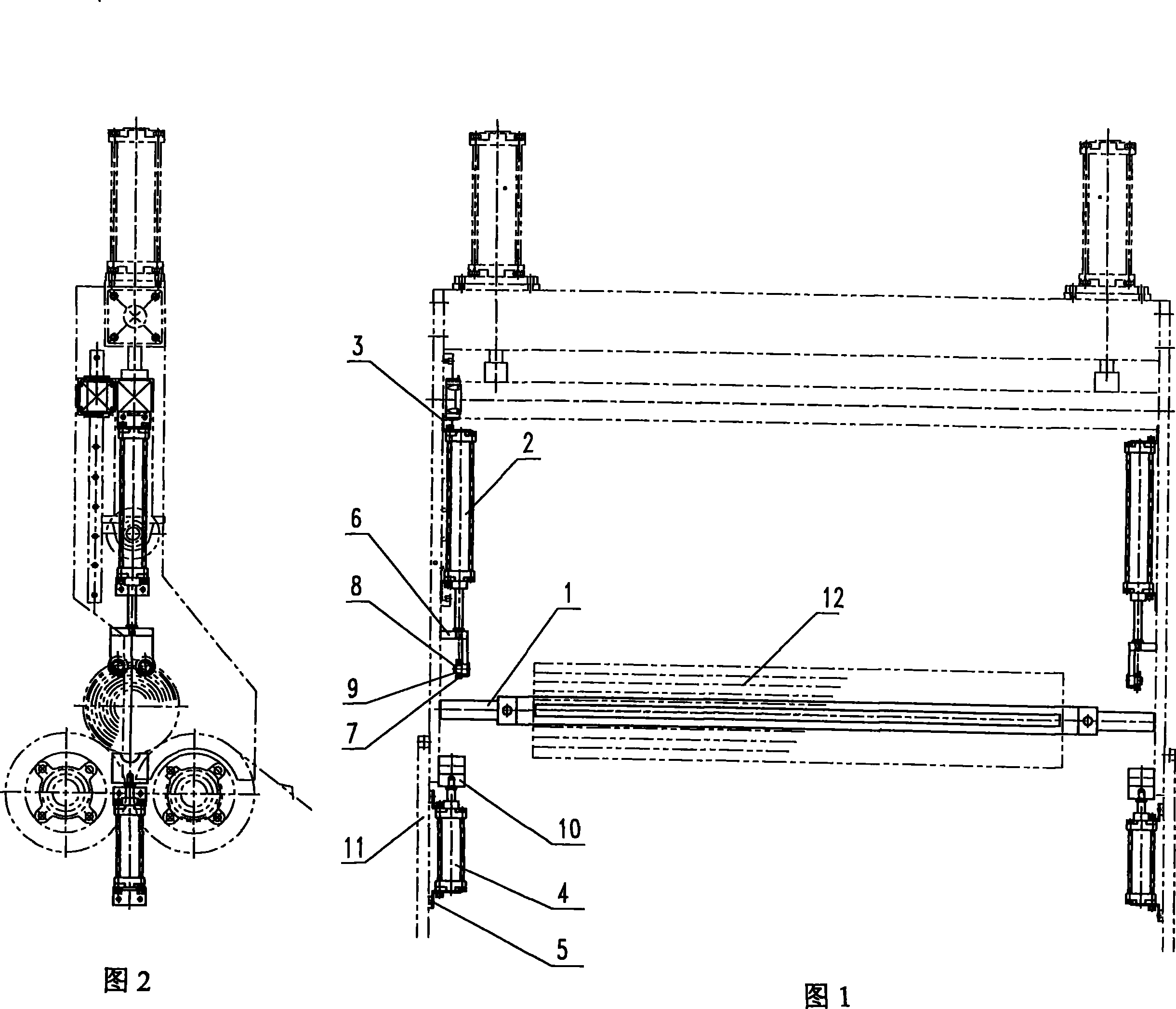

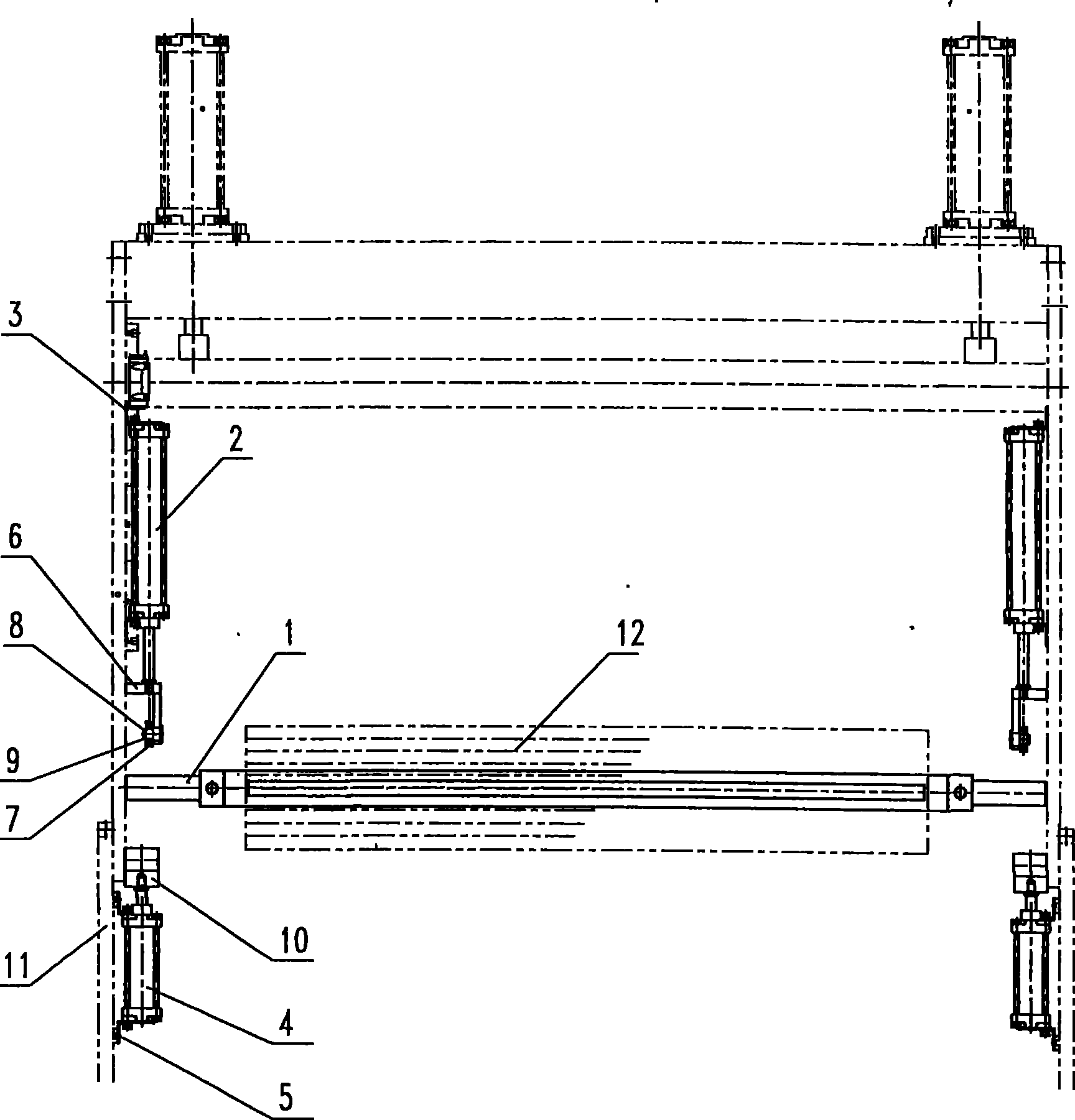

[0013] Below in conjunction with accompanying drawing and embodiment the present invention will be further described

[0014] This embodiment is a coiling device of a plastic coiling machine used on a rubber cloth extruder with a wheel surface of 1600mm, including: a coiling shaft 1 with a diameter of ∮50mm, an upper pressure cylinder 2 of LB type ∮63x120st, and an upper cylinder The fixed bolt 3 is M 8, the lower pressure cylinder 4 is LB type ∮63x120st, the lower cylinder fixed bolt 5 is M 8, the bearing fixing seat 6, the model specification of the deep groove ball bearing 7 is 6304, and the diameter of the bearing fixing pin 8 is ∮ 20mm, buckle spring 9, tile-shaped bracket 10, frame 11 and rolled plastic 12, of which: except the take-up shaft is 1 piece, the number of other parts is 2 pieces; the upper pressure cylinder 2 and the lower pressure cylinder Cylinder 4 is on the same center line, and is fixed on the frame 11 by upper cylinder fixing bolt 3 and lower cylinder f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com