Intelligent electroplating production line capable of achieving number increasing and decreasing and replacing of hanging racks through rotary transposition

A plating production line and hanger technology, applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of inability to realize automatic processing, low efficiency, hidden safety hazards, etc., and achieve the effect of fast speed, fast transposition speed, and high adjustment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

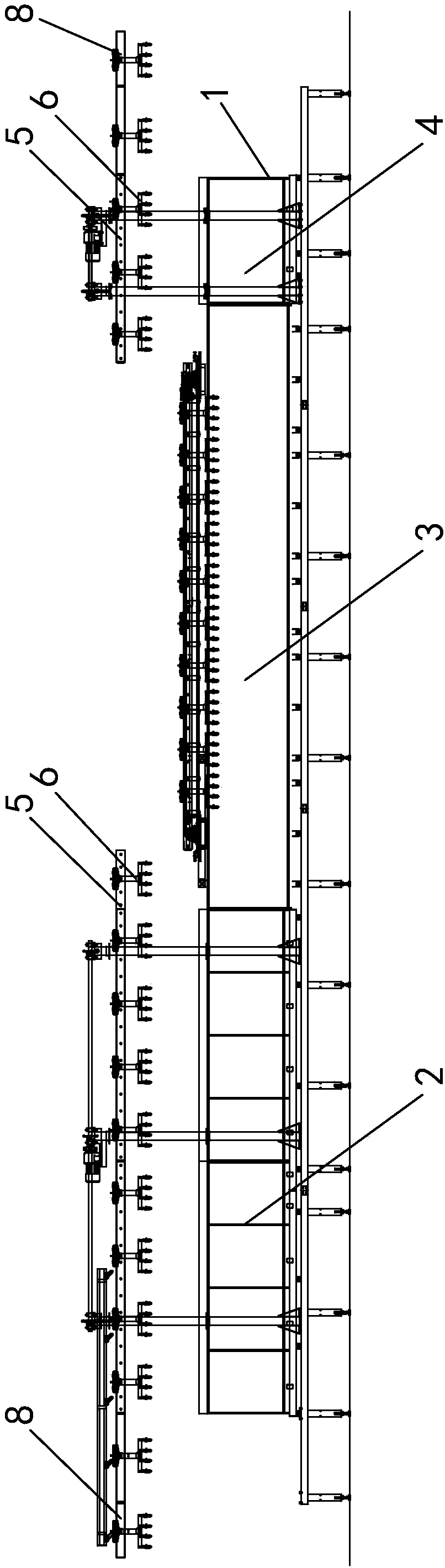

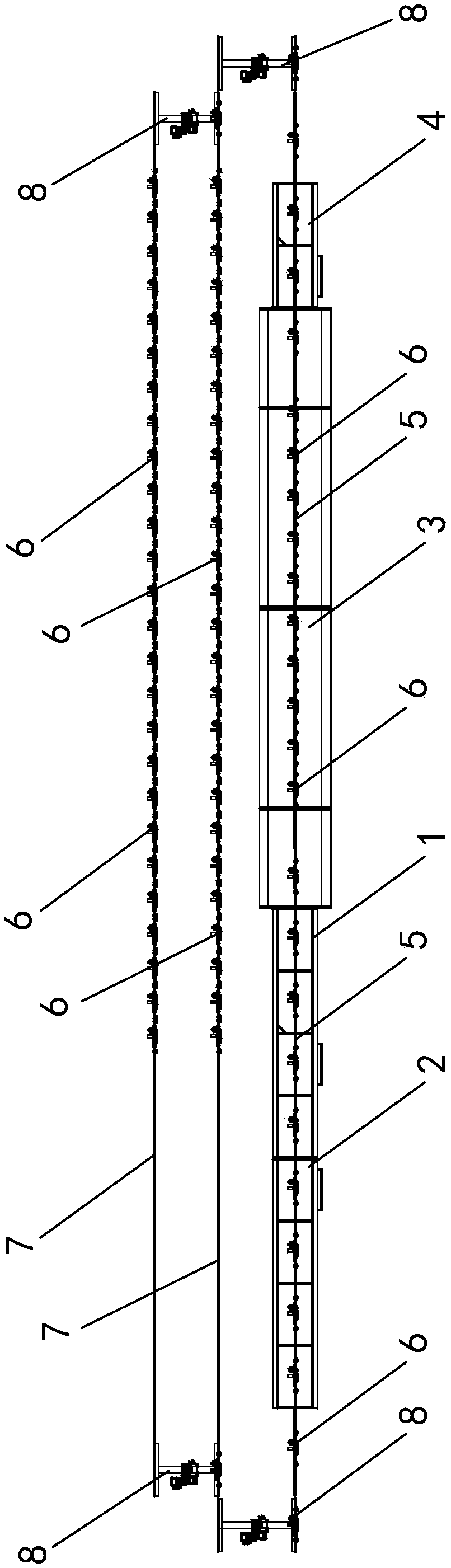

[0031] Example: see attached Figure 1~2 As shown, an intelligent electroplating production line that rotates, changes positions, increases, decreases, and replaces racks includes a rack body 1, and the rack body 1 includes a pretreatment section 2, an electroplating section 3, and Post-processing section 4; above the frame body 1, a hanger translation track 5 is horizontally arranged along the length direction of the frame body 1, and a plurality of electroplating hangers 6 are slidably arranged on the hanger translation track 5;

[0032] Also includes two hanger storage tracks 7, each of the hanger storage tracks 7 and the hanger translation track 5 are arranged parallel to the front and rear directions, and each hanger storage track 7 is slidingly provided with a plurality of electroplating hangers 6, and The specifications of the plating hangers 6 on different hanger storage tracks 7 are different.

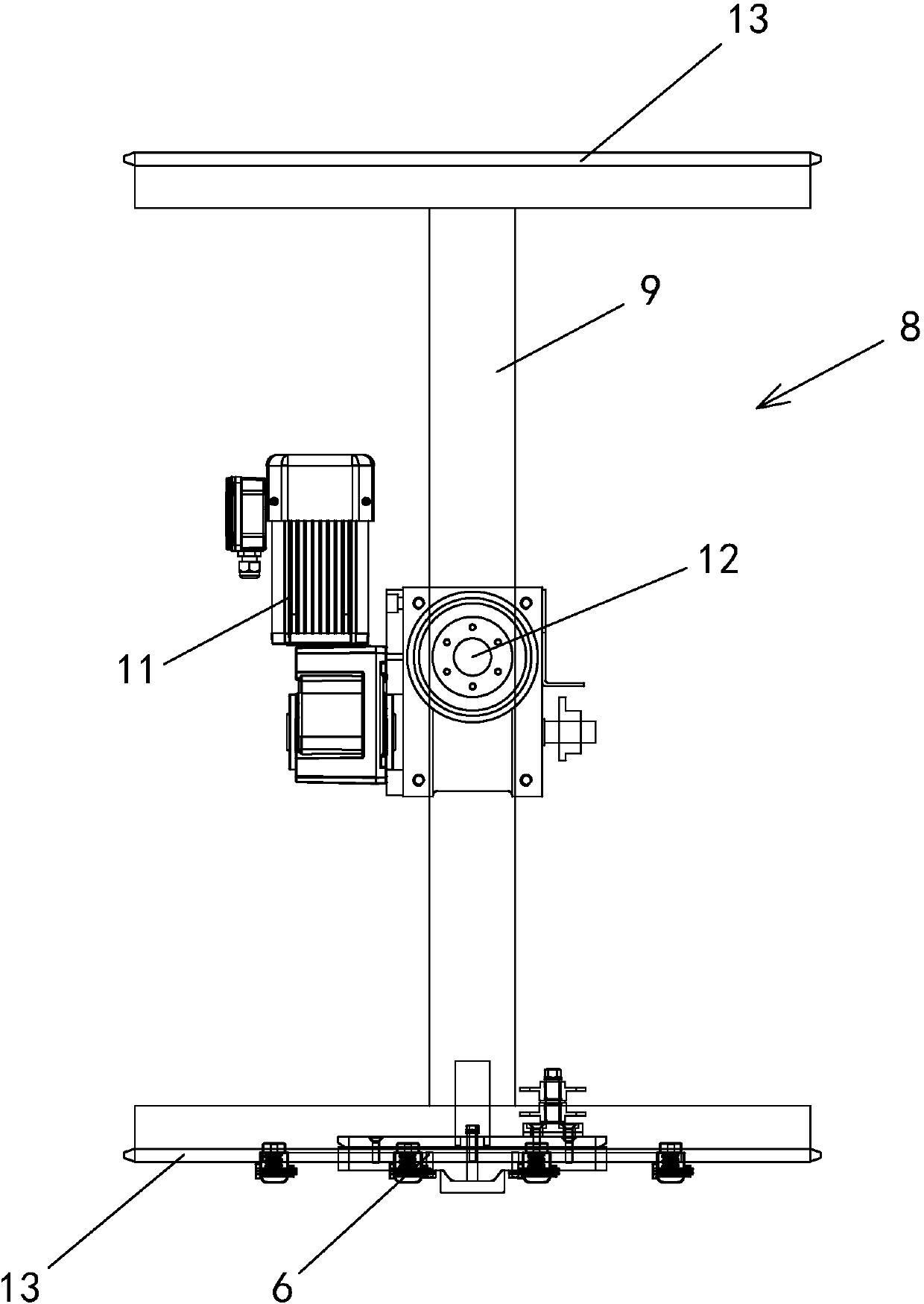

[0033] It also includes four rotating mechanisms 8, and each two rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com