A semi-automatic coupling pre-tightening device

A semi-automatic, pre-twisting technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., to achieve the effect of flexible operation, overcome manual operation, and save production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the present invention is described in further detail:

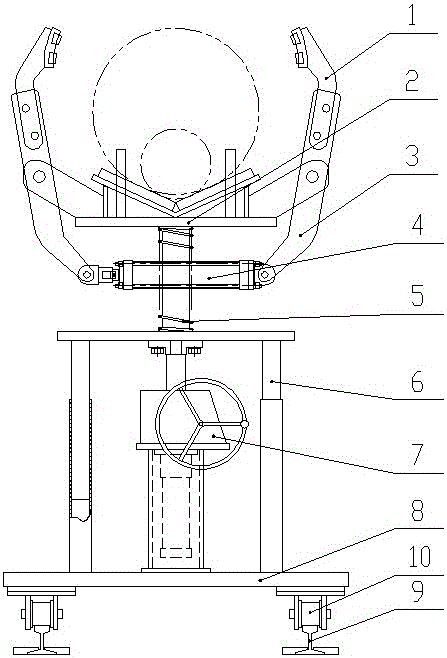

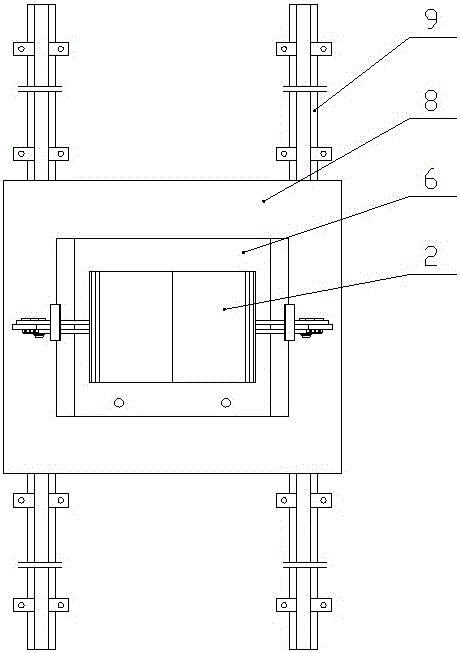

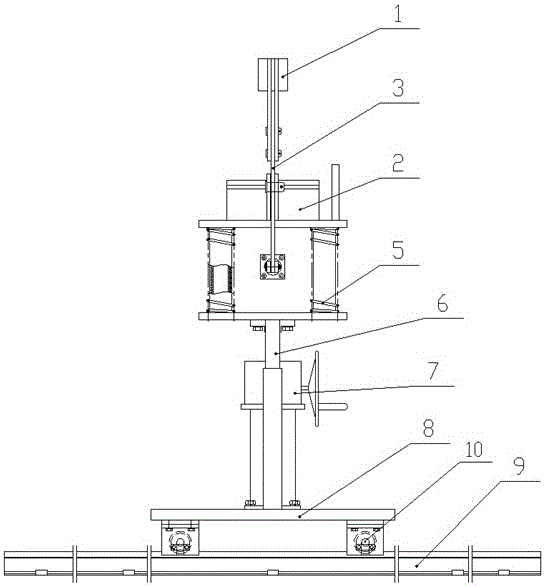

[0015] like figure 1 , figure 2 , image 3 , as shown, a semi-automatic coupling pre-tightening device is composed of a splint 1, a floating frame 2, a force arm 3, a cylinder 4, a spring 5, a lifting frame 6, an elevator 7, a base 8 and a guide rail 9. A lifter 7 is fixedly welded on the base 8, and the other end of the lifter 7 is connected to the lifting frame 6, and the guide rod welded at the bottom of the lifting frame 6 is inserted into the guide steel pipe on the base 8 top. Elevator 7 can promote hoist frame 6 to move up and down to adapt to couplings of different pipe diameters. Lifting frame 6 connects floating frame 2 through spring 5. The spring 5 can make the floating frame 2 move up, down, left, right, back and forth, so as to facilitate the smooth connection between the centering collar and the center of the oil casing. like Figure 4 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com