Reflexion type light-valve minisize projection apparatus

A micro-projector and reflective technology, which is applied in optics, instruments, optical components, etc., can solve the problems that the utilization rate of light energy needs to be improved, so as to improve the utilization rate of light energy, reduce the cost of design and processing, and facilitate miniaturization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

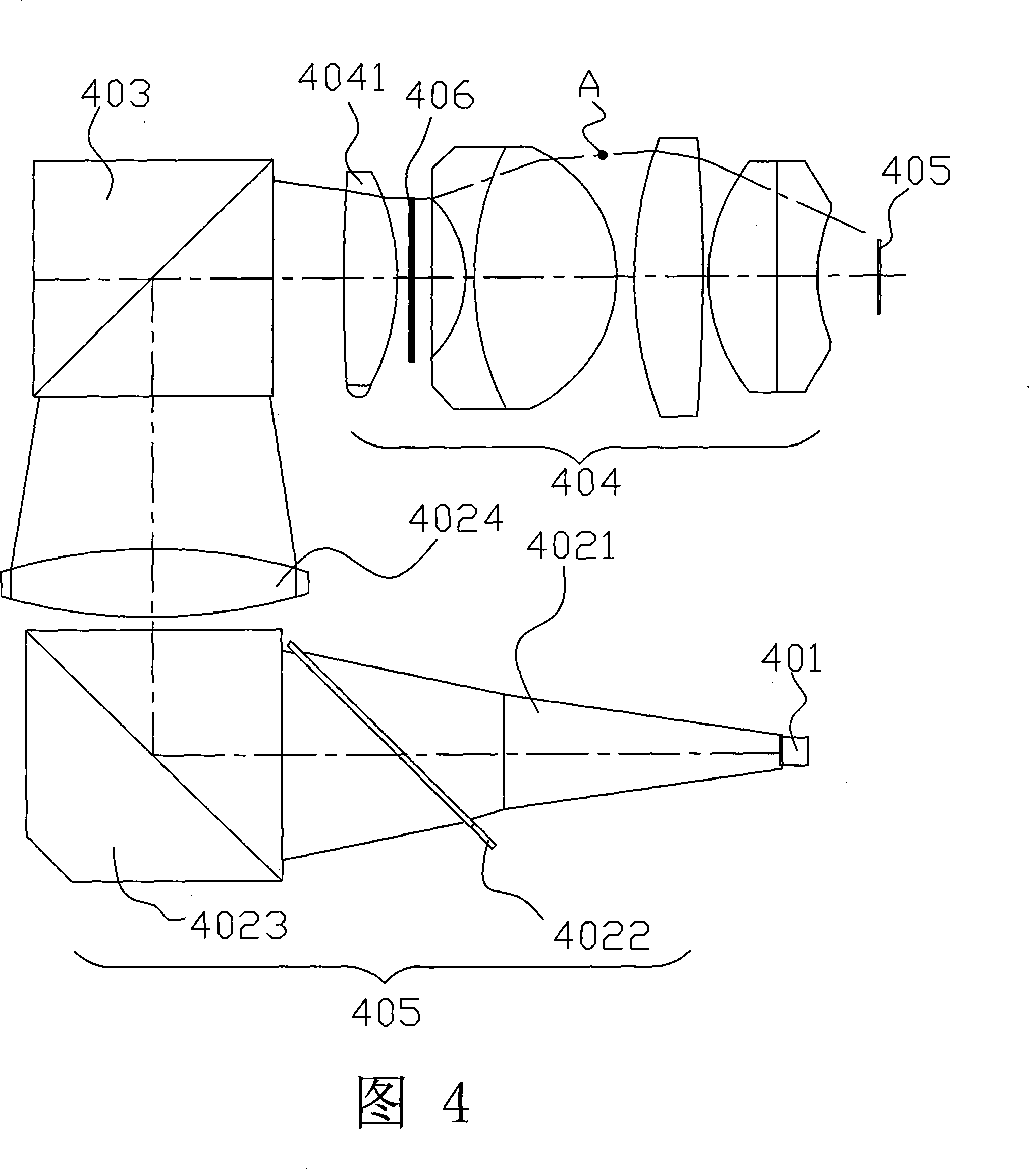

[0038] Embodiment 1, as shown in FIG. 4 , the lighting source 401 adopts a plurality of single-color LEDs, and the light emitted by the LEDs is passed through the light mixing tube 4021 of the lighting optical system 402, and each LED is subjected to light mixing treatment to make the light uniform. Afterwards, it is synthesized into a colored or white light beam by the dichromatic mirror 4022, and then enters the PBS403 through the polarizer 4023 and the illumination lens 4024. Reflected by the PBS 403 into the first mirror 4041 of the projection objective 404 , the aperture stop 406 is located behind the first mirror 4041 of the projection objective 404 , close to the PBS 403 . Finally, the projection objective lens 404 and the illumination optical system 402 together irradiate the light emitted by the LED onto the reflective light valve 405 substantially uniformly, and each pixel of the reflective light valve 405 respectively modulates the illumination light and transforms t...

Embodiment 2

[0039]Embodiment 2, as shown in FIG. 5 , the lighting source 501 adopts a plurality of single-color LEDs, and the light emitted by the LEDs is passed through the light mixing tube 5021 of the lighting optical system 502, and each LED is subjected to light mixing treatment to make the light uniform. Afterwards, it is synthesized into a colored or white light beam by the dichromatic mirror 5022, and then enters the PBS503 through the polarizer 5023 and the illumination lens 5024. Reflected by the PBS 503 into the first mirror 5041 of the projection objective 504 , the aperture stop 506 is located in front of the first mirror 5041 of the projection objective 504 , close to the PBS 503 . Finally, the projection objective lens 504 and the illumination optical system 502 together irradiate the light emitted by the LED onto the reflective light valve 505 substantially uniformly, and each pixel of the reflective light valve 505 respectively modulates the illumination light and transfor...

Embodiment 3

[0040] Embodiment 3, as shown in FIG. 6 , the lighting source 601 adopts a plurality of single-color LEDs, and the light emitted by the LEDs is passed through the light mixing tube 6021 of the lighting optical system 602, and each LED is subjected to light mixing treatment to make the light uniform. Afterwards, it is synthesized into a colored or white light beam by the dichromatic mirror 6022, and then enters the PBS603 through the polarizer 6023 and the illumination lens 6024. The aperture stop 606 is located in front of the PBS 603 after being reflected by the PBS 603 into the first mirror 6041 of the projection objective 604 . Finally, the projection objective lens 604 and the illumination optical system 602 together irradiate the light emitted by the LED onto the reflective light valve 605 substantially uniformly, and each pixel of the reflective light valve 605 respectively modulates the illuminating light and transforms the polarization state of the incident light, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com