Impeller type rotor engine

A rotary engine and impeller-type technology, which is applied in the direction of combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems of precise manufacturing and rapid development of combustion efficiency constraints, and achieve easy precise machining and grinding, and reduce design and processing costs , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

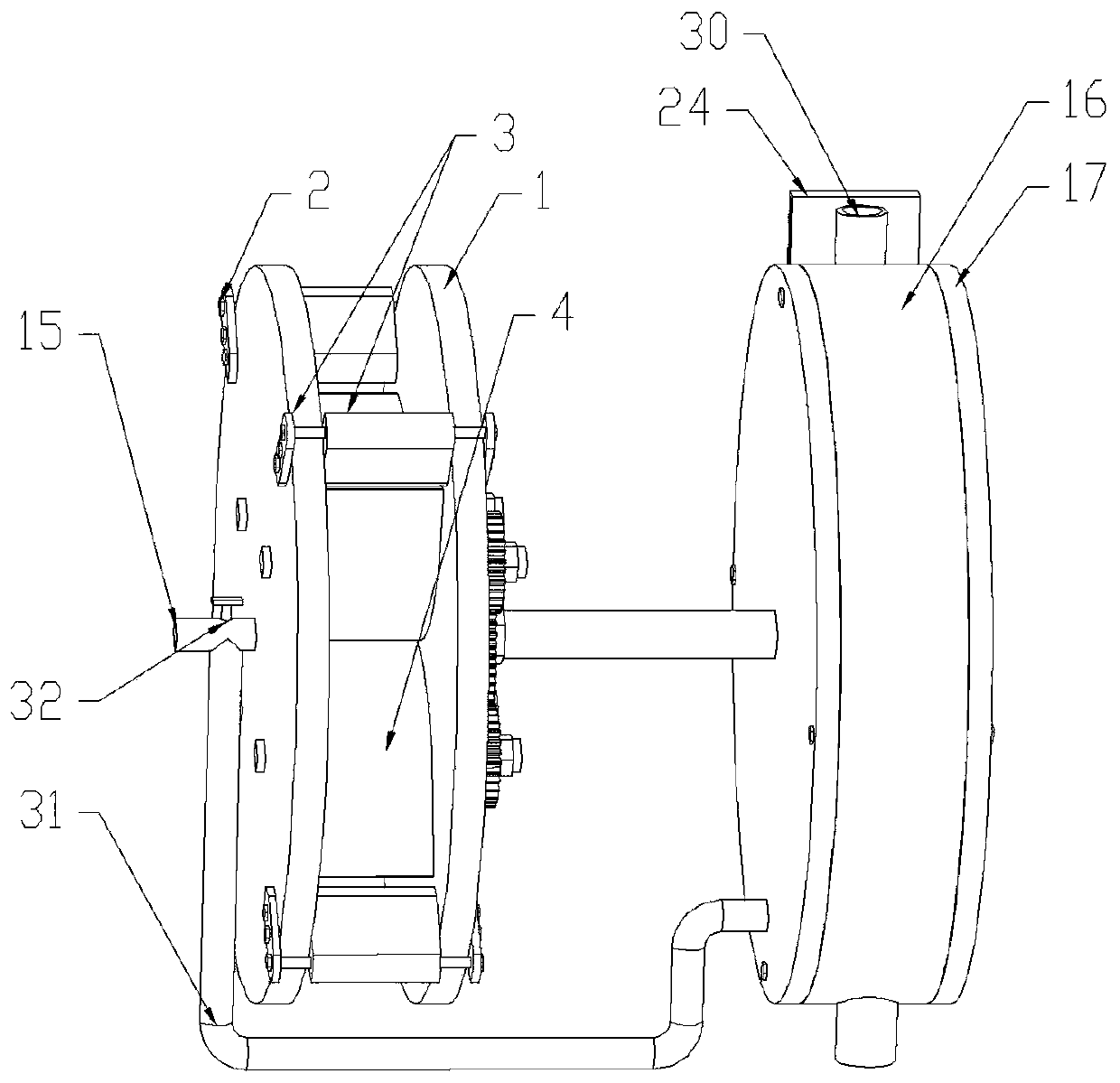

[0029] like figure 1 As shown, the rotary engine described in the present invention includes a first cylinder block and a second cylinder block 16, and the walls of the second cylinder block 16 and the second rotor 18 form several combustion chambers; A rotor compresses and delivers gas to any combustion chamber of the second cylinder 16 to perform work; the second rotor 18 rotates coaxially with the first rotor.

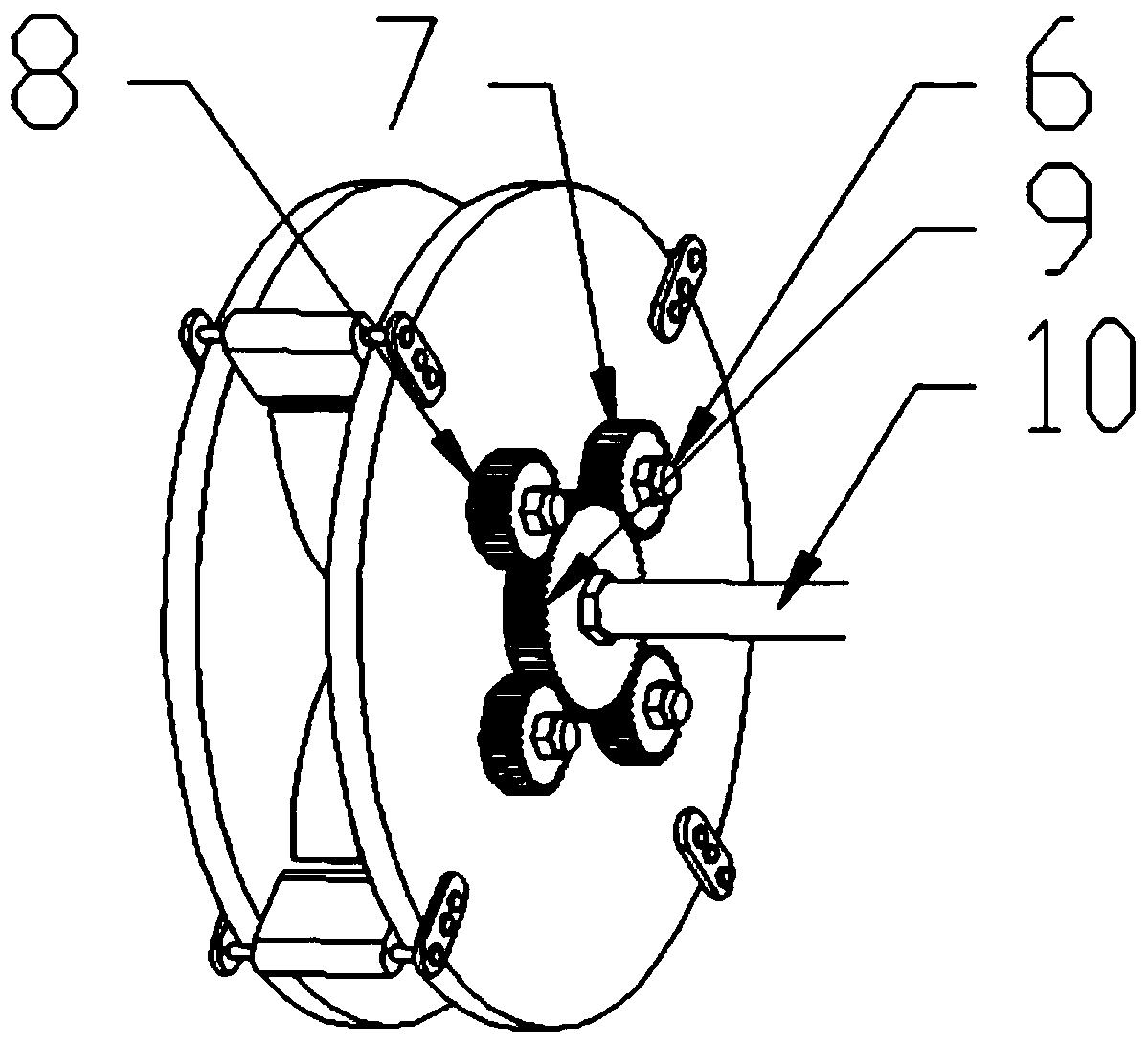

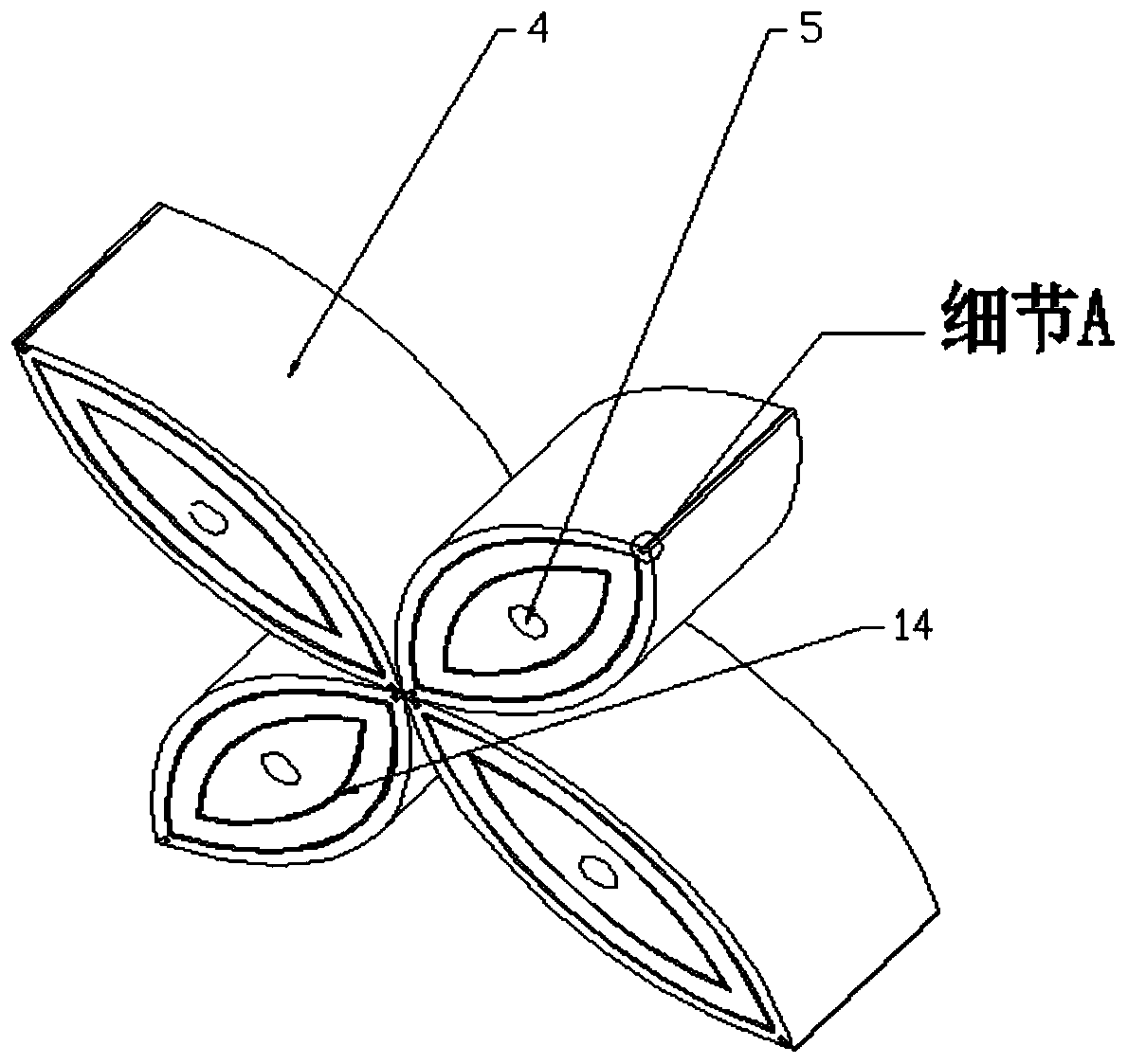

[0030] like figure 2 As shown, two first end covers 1 are fixed on both sides of the first rotor by screws 2 and fixing plates 3 to form a first cylinder body; image 3 As shown, the first rotor includes several impellers 4 and a rotating device, and several of the impellers 4 are evenly distributed in the first cylinder, and the volume of the cavity formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com