Automatic guiding carriage device

A technology of automatic guidance and trolley, applied in the direction of drying solid materials, drying solid materials without heating, lighting and heating equipment, etc., can solve problems such as artificial pollution, achieve the effect of increasing productivity and reducing artificial pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

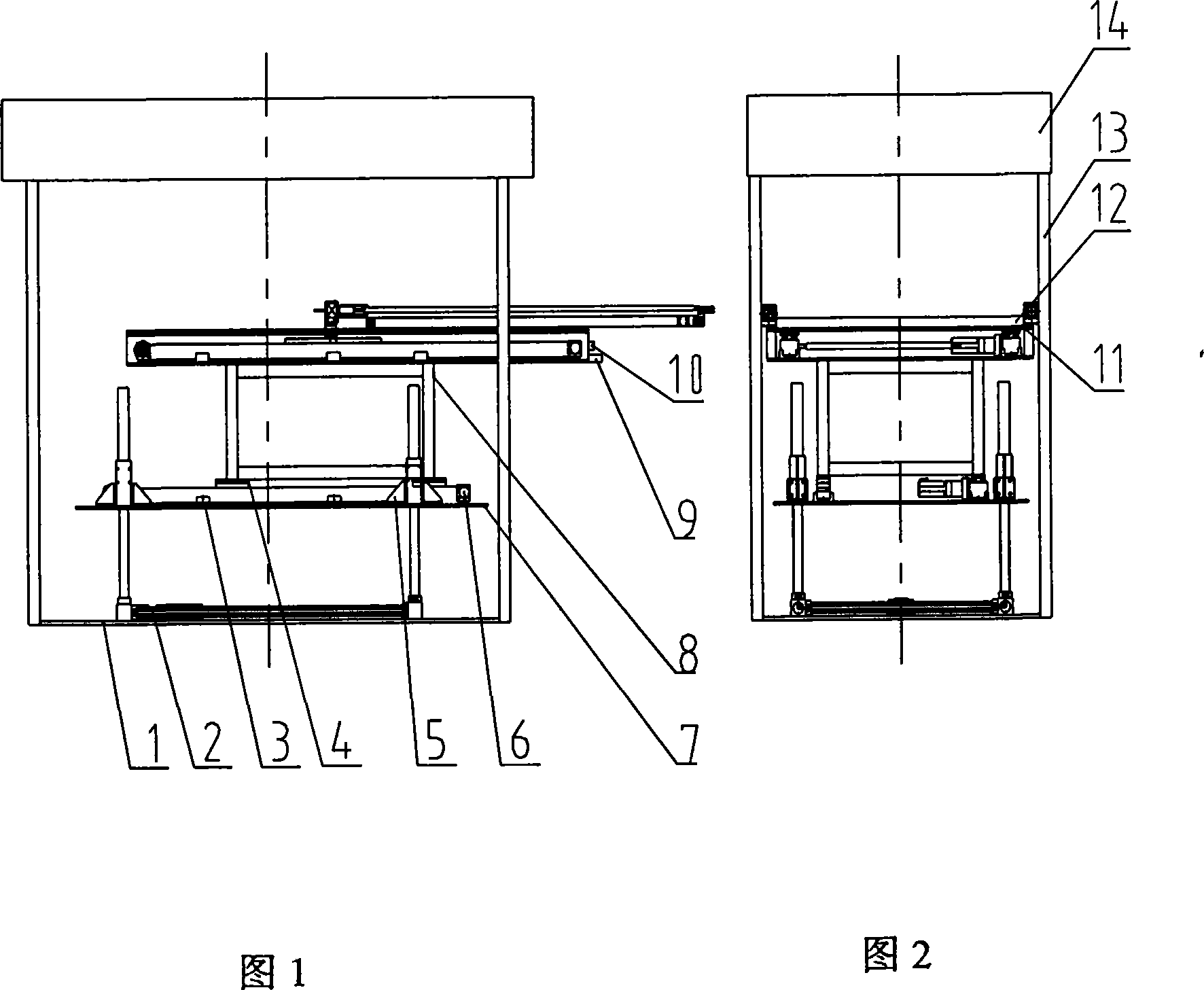

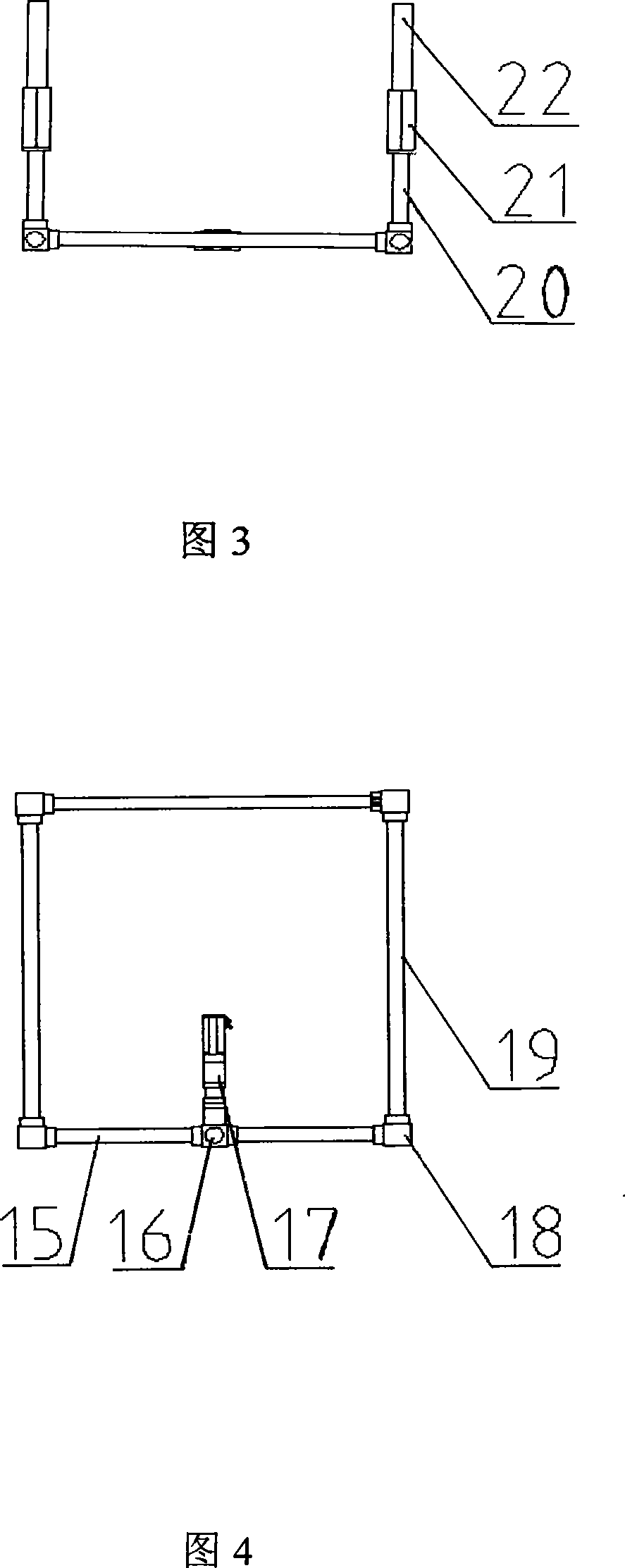

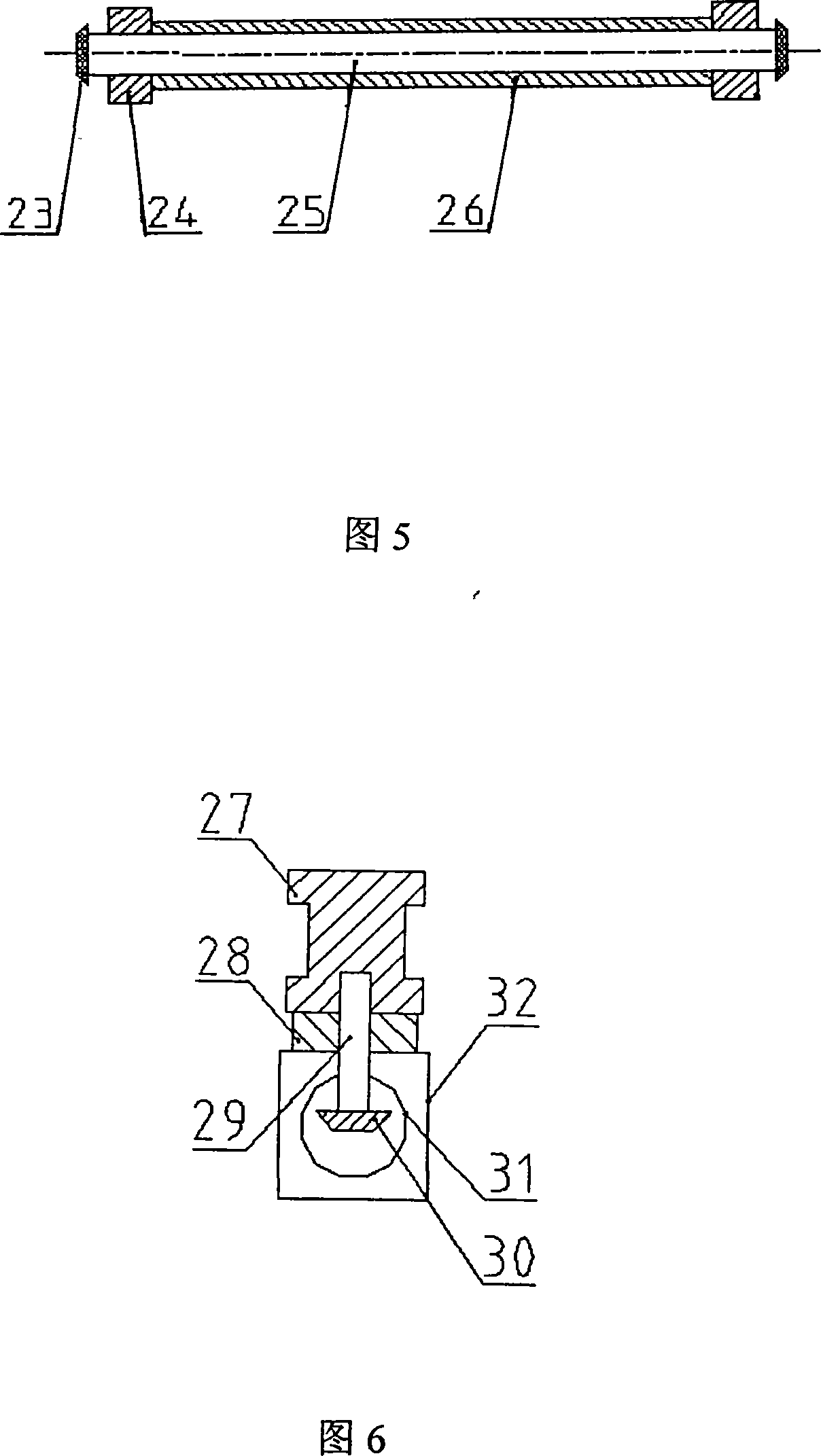

[0021] As shown in Figures 1 and 2, it is a schematic structural diagram of an automatic guided trolley device. The described automatic guided trolley device consists of a slider connecting plate 1, a lifting platform linear positioning system component 2, an adjustment mounting block 3, and a fixing piece 4 , mounting base 5, docking station linear positioning system assembly 6, slider connecting plate 7, support frame 8, vertical positioning sensor 9, horizontal positioning sensor 10, loading platform 11, material catcher frame assembly 12, bracket 13 and fan filter The device 14 is composed.

[0022] The slider connecting plate 1 and the bracket 13 form the box body of the automatic guided trolley device. The slider connecting plate 1 is connected to the slider of the X-track linear positioning system, and it is connected to the slider of the X-track linear positioning system to realize the movement in the X direction. Move left and right, so that the loading platform 11 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com