Wig ground with novel periphery structure

An edge structure and basic mesh technology, applied in wigs, clothing, applications, etc., can solve the problems of unsightly, rigid, unnatural transition, etc., and achieve the effect of good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

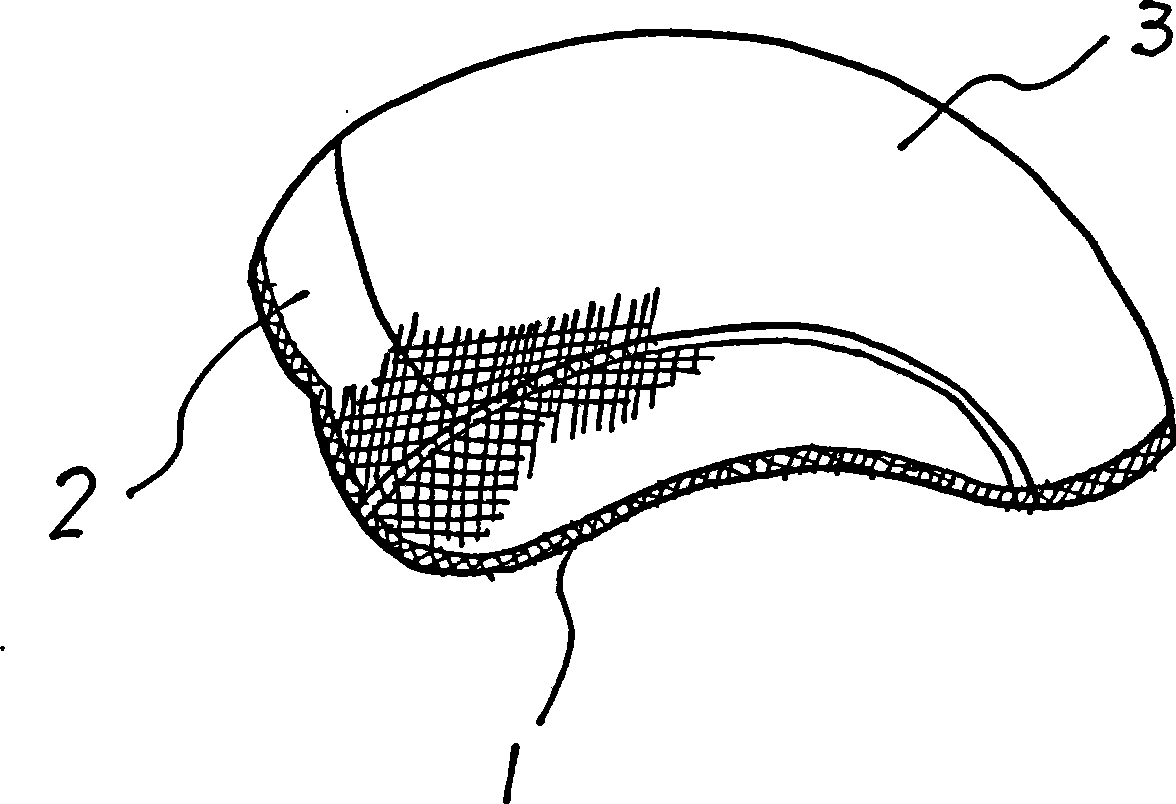

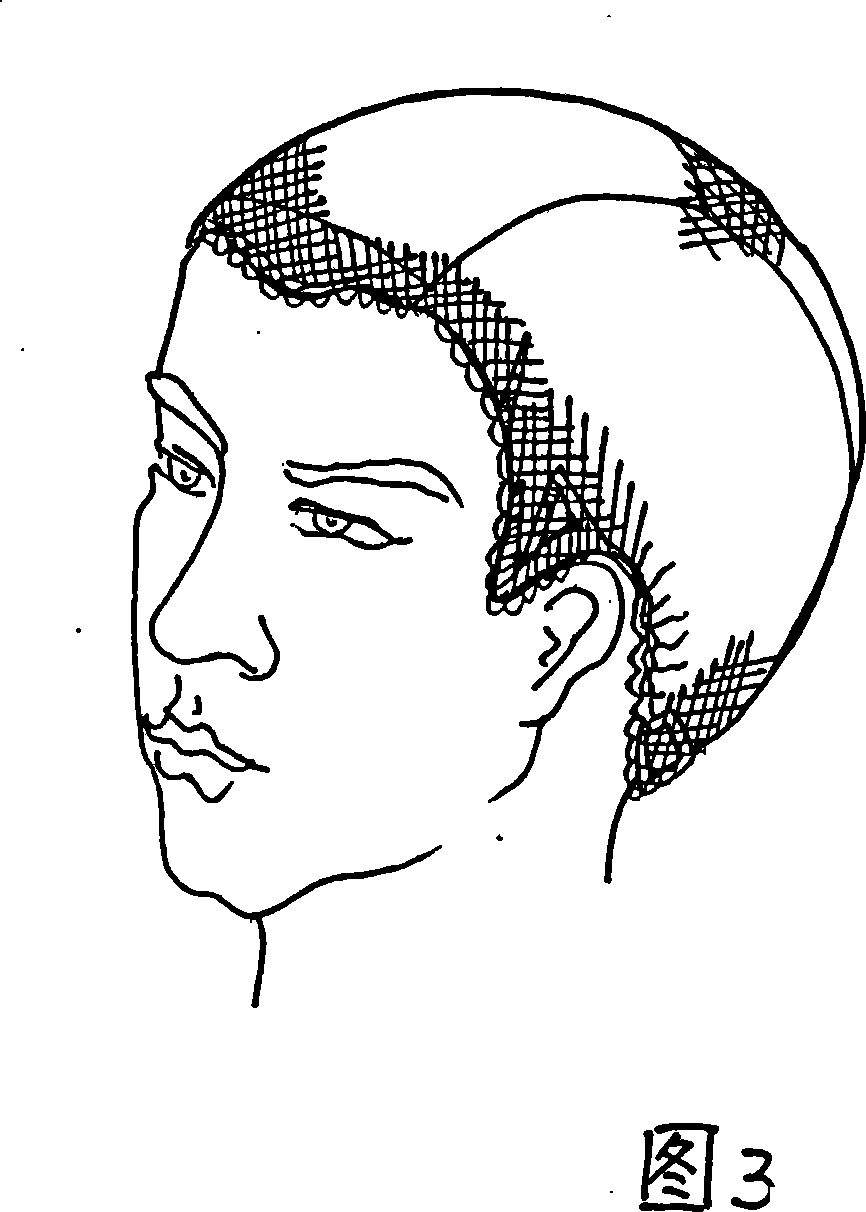

[0025] The present embodiment is made of filaments, and the edge portion 1 of the basic net 3 is sewn with a hollow lace 5 . The hollow lace 5 is sewn into a continuous curved shape 6 at the front edge 2 or the rear edge 4 of the wig basic net 3 . The hollow lace 5 stitched into a continuous curved undulating shape can be continuous S-shaped or continuous pointed. Of course, there is no seam in the special case of the hollow lace 5 stitched into a continuous curved shape 6 at the front edge 2 or rear edge 4 of the wig base net 3. Make continuous curved shape 6, but common arc shape.

[0026] Hollow-out lace 5 is a decorative strip-shaped textile made of cotton thread, hemp thread, silk thread or polyester thread as raw material through weaving. The width of the hollow lace should be 3-20mm; the best width is 3-10mm, and the present embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com