Bamboo board with curve textures

A texture and curve technology, which is applied in the field of bamboo boards with curved texture, can solve the problems affecting the appearance and market price, straight bamboo texture, poor bending resistance, etc., and achieve the effect of rich appearance texture, full of changes, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

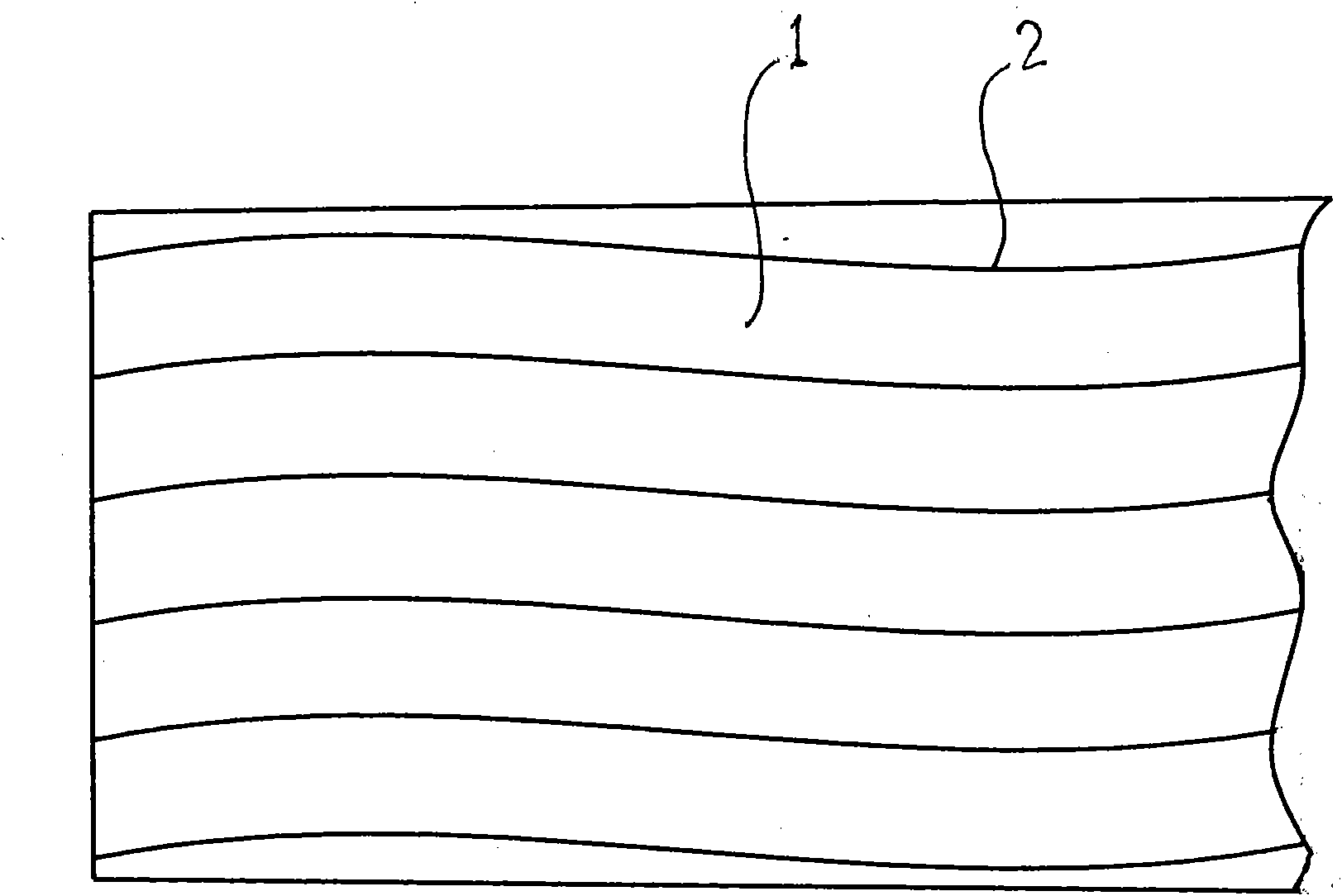

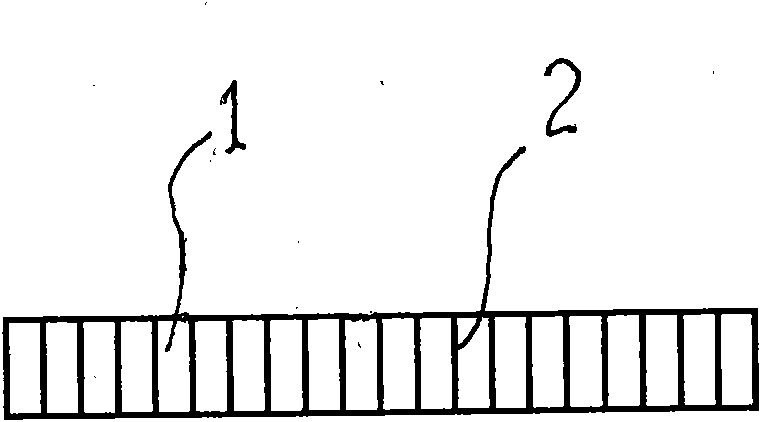

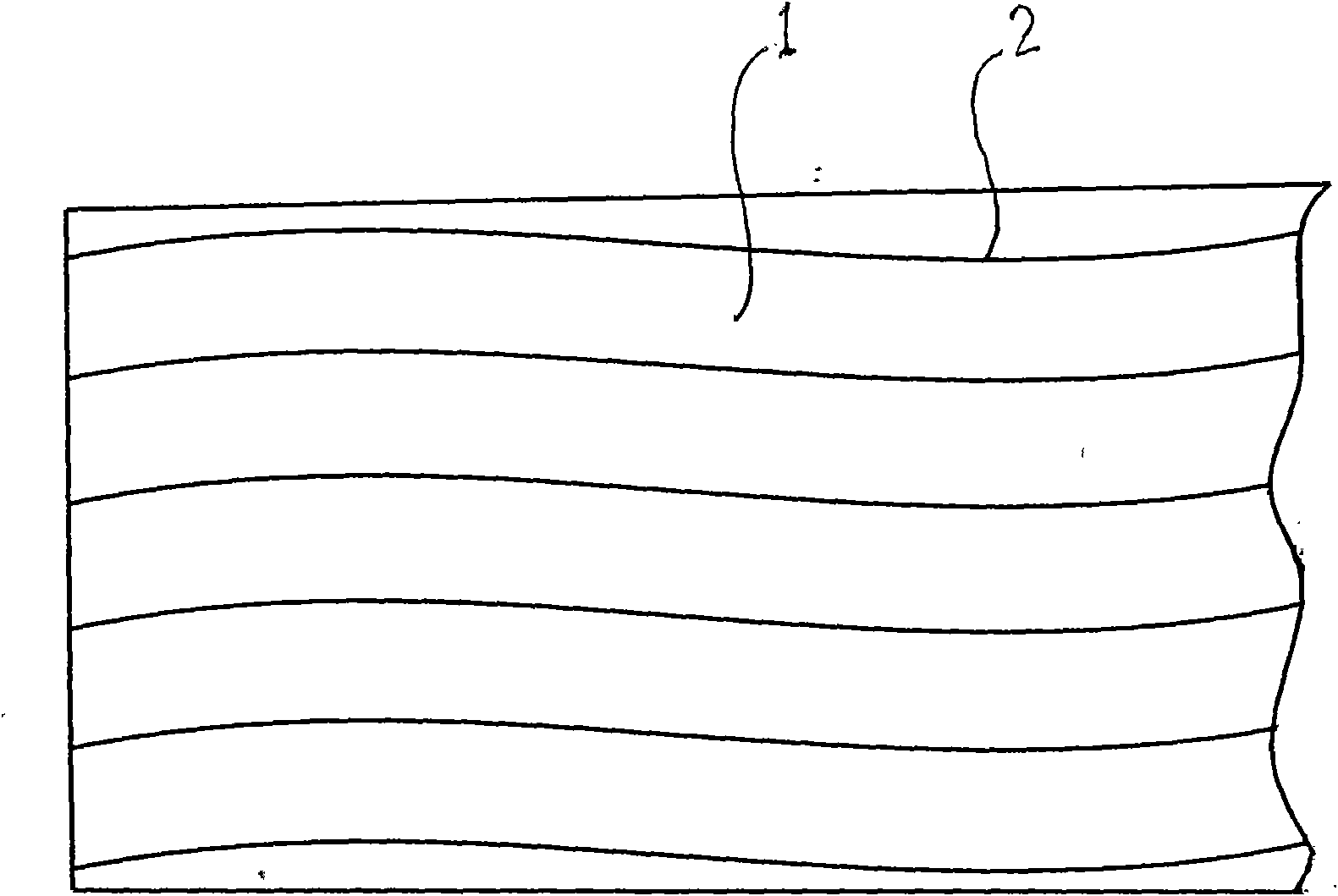

[0011] Such as figure 1 , 2 Shown, the present invention has the bamboo plate of curvilinear texture, comprises some bamboo slices 1 that stick to each other, and bamboo slices 1 are bonded together with its wider face (also can be bonded together with narrower face; Bamboo slice can vertically, also can lay flat), the bamboo slices pasted together are bent (curved and finalized after molding), the sticking surface 2 of the bamboo slices 1 is a curved surface, and the upper and lower sides of the bamboo plate have ( Render) Curve Texture.

[0012] Bamboo chip 1 is conventionally prefabricated and glued by the requirements of required bamboo boards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com