Pneumatic servobrake and diaphragm therefor

A pneumatic brake and booster technology, applied in the direction of brakes, brake transmissions, diaphragms, etc., can solve problems such as leaking, deterioration of diaphragm assembly, and no longer ensuring sealing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

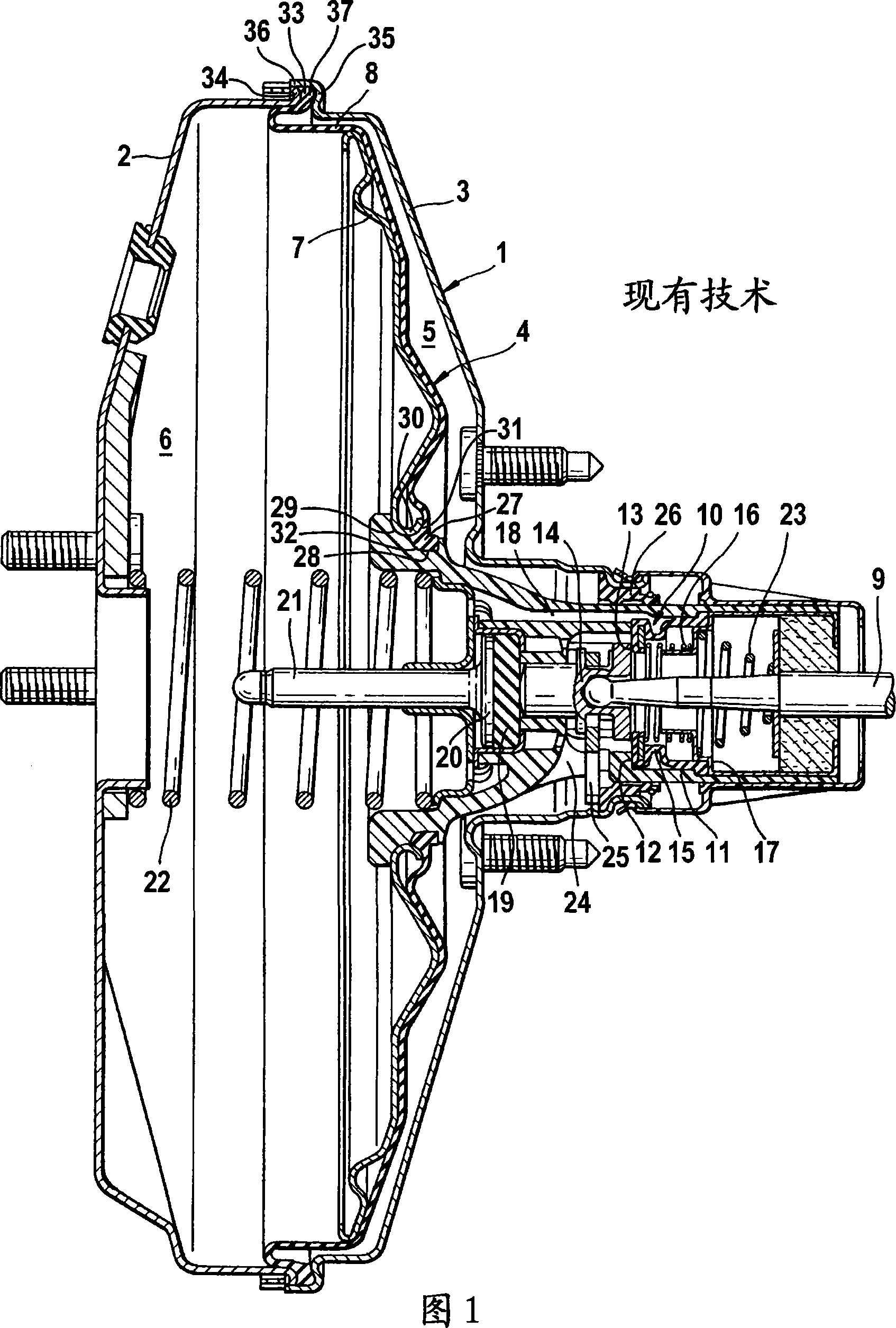

[0021] As shown in FIG. 1 , the only schematically indicated booster housing 1 of a prior art pneumatic brake booster for a motor vehicle braking system comprises a first housing half-cover 2 and a second housing half-cover 3 , so The two housing halves are pressed together force-fittingly by means of forming techniques, for example connected by recesses. The booster housing 1 is divided into a working chamber 5 and a low-pressure chamber 6 by an axially movable wall 4 . The axially movable wall 4 comprises a diaphragm 7, for example deep-drawn from sheet metal, and a flexible diaphragm 8 resting on the diaphragm, which is connected to the booster housing 1 at the outer periphery of the diaphragm 7. A rolling membrane is formed between them, which serves as a seal between the two chambers 5 , 6 and between the two chambers 5 , 6 and the environment.

[0022] A control valve 10 actuatable by an input 9 is arranged in a control housing 11 which is sealed in and guided by the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com