Direct current compressor drive circuit

A technology of DC compressor and drive circuit, applied in the direction of DC motor speed/torque control, AC motor control, electrical components, etc., can solve the problems of high hardware cost and high product competition pressure, so as to reduce hardware cost and ensure control Quality and the effect of improving market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

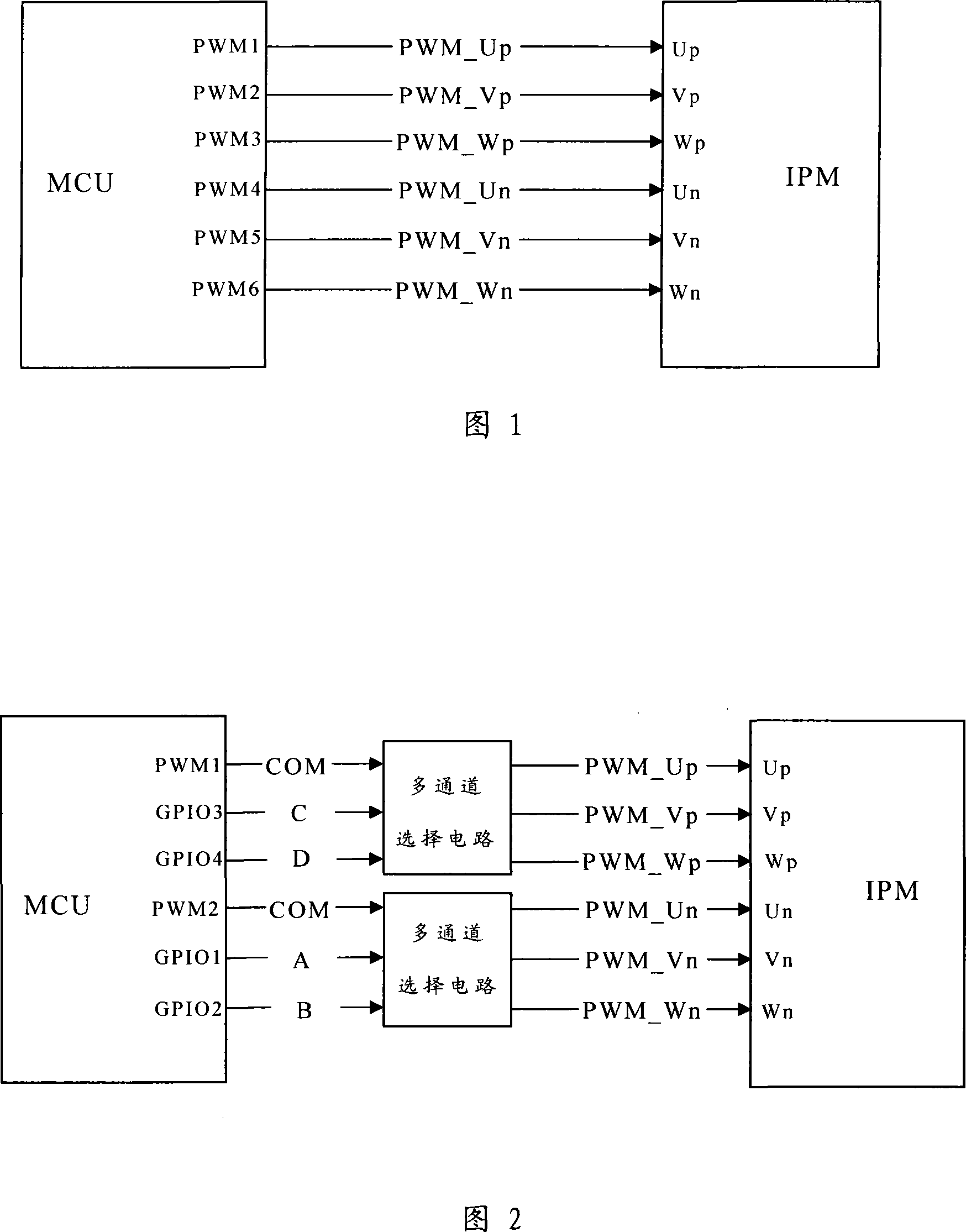

[0034] Example 1, see Figure 5 As shown, this embodiment takes the MCU chip IC101 with four PWM output ports as an example to specifically describe the connection structure between it and the inverter circuit IPM.

[0035] The MCU chip IC101 itself has four PWM output ports, namely RC5, RC4, RC3, RC2. The four PWM outputs cannot meet the control requirements of the three-phase DC motor. Therefore, one of the PWM output ports needs to be expanded to Realize 6-way PWM output.

[0036] like Figure 5 As shown, the 3 PWM output ports RC3, RC4 and RC5 of the MCU chip IC101 are directly connected to the three-phase DC positive terminals Up, Vp and Wp of the inverter circuit IPM in a one-to-one correspondence, and the fourth PWM output port RC2 is connected to a multi-channel Select the common terminal of the circuit. The multi-channel selection circuit can be implemented by a 4-channel selection chip IC102, whose common terminal CY is connected to the fourth PWM output port RC2 ...

Embodiment 2

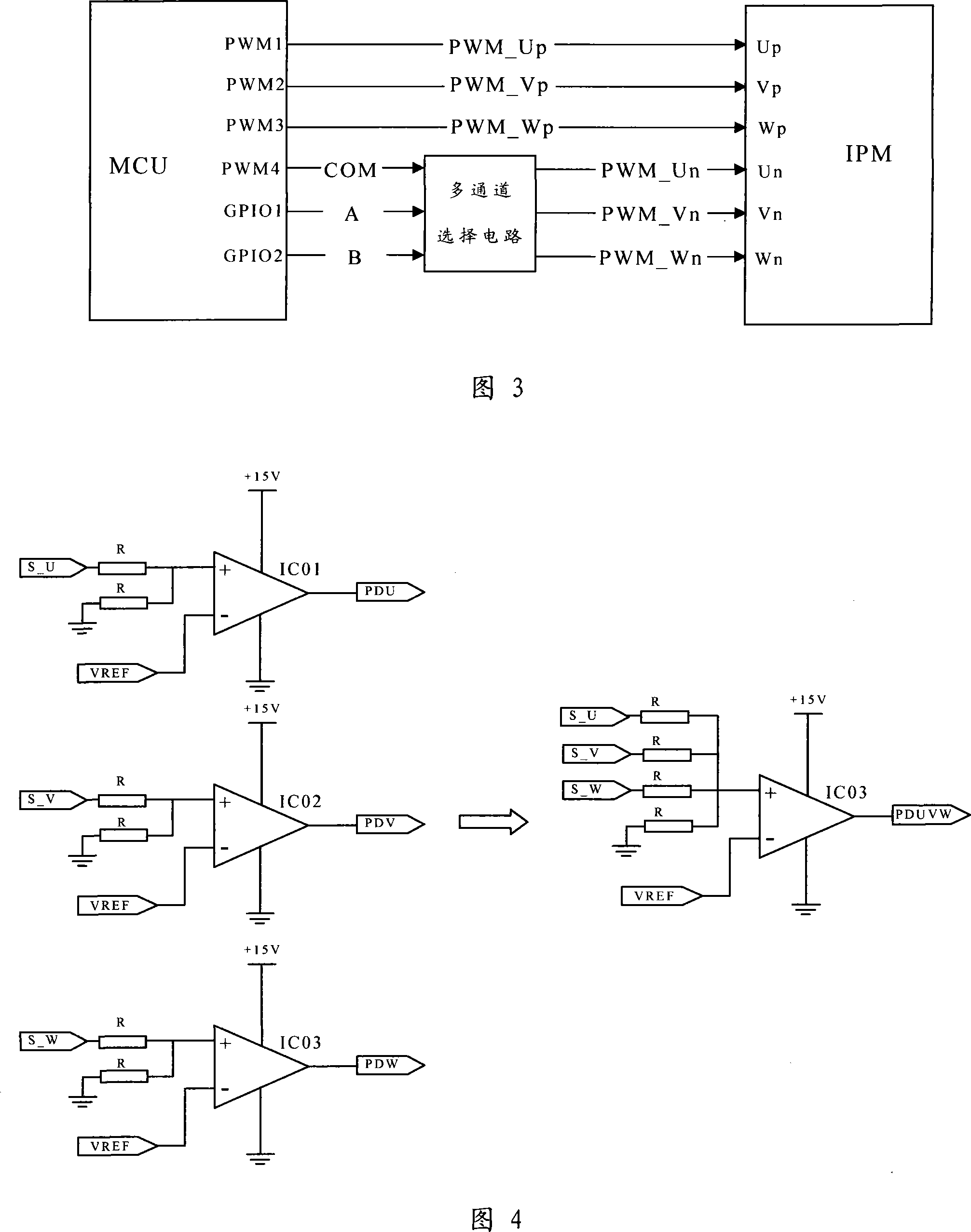

[0037] Example 2, see Image 6 As shown, this embodiment specifically describes the implementation structure of the DC compressor rotor position detection circuit.

[0038] The three-phase electromotive force voltages S_W, S_V, S_U sampled from the three-phase terminals of the DC compressor are limited by the voltage divider and current limiting network composed of resistors R301 / R302 / R303, R304 / R305 / R306, R307 / R308 / R309 respectively. After the summation and voltage division processing, the non-inverting input terminal of the comparator IC03 is connected, and the comparator IC03 can be specifically implemented by an operational amplifier chip. The inverting input terminal of the comparator IC03 is connected to the DC bus through a voltage divider and current limiting network composed of resistors R312, R316, and R317, and the DC bus voltage DC+ is divided and used as a reference voltage. Since the rotation of the compressor rotor will generate back EMF, and the magnitude of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com