Method for manufacturing high-yield strength cuprum flat wire and wire-drawing device

A technology of yield strength and copper flat wire, which is applied in the field of transformers, can solve problems such as difficult control, high tooling requirements, and high manufacturing costs, and achieve the effects of prolonging service life, good winding process, and improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

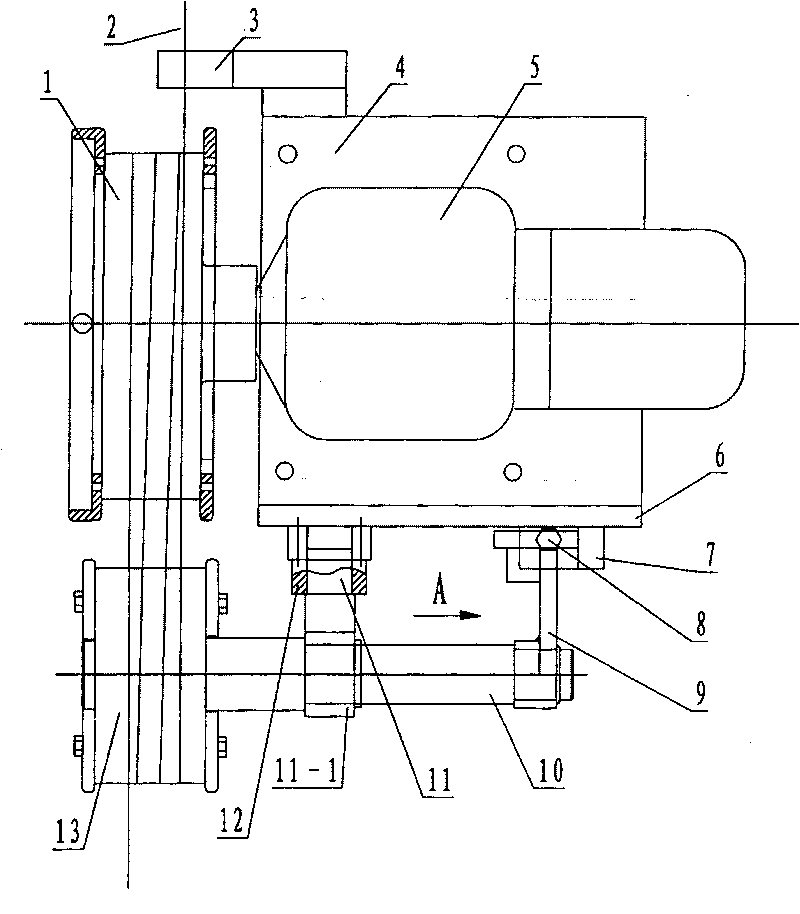

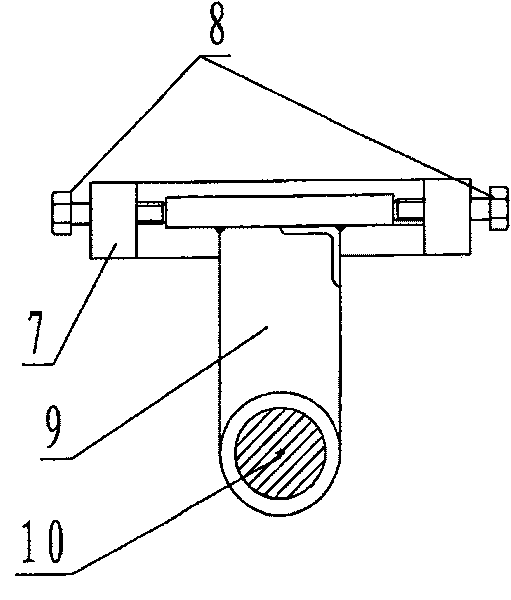

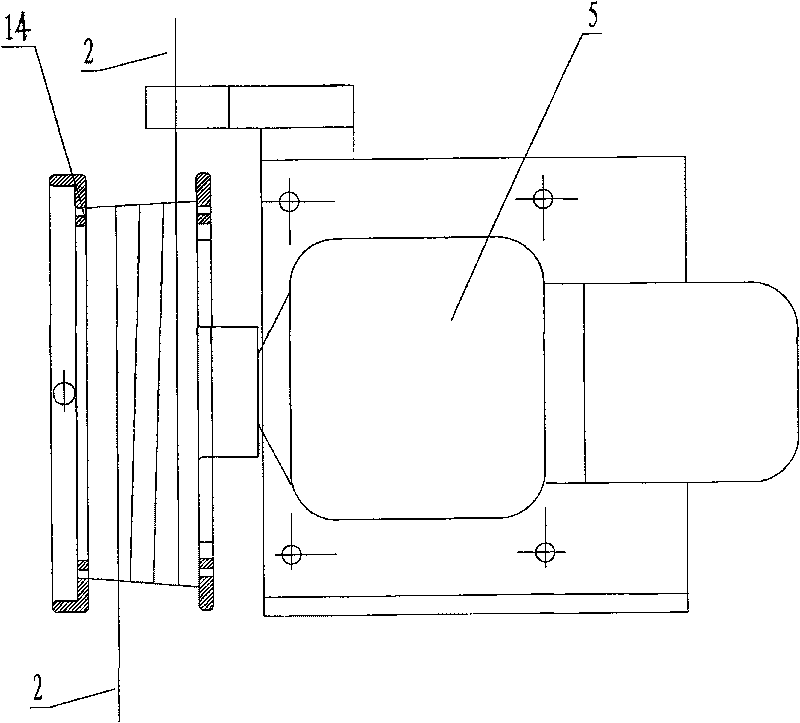

[0017] The inventive method mainly is made of following three steps: 1. selected semi-finished soft copper flat wire cross-sectional size: according to the length and width of the cross-section in the copper flat wire wire drawing process, its yield strength increases by 50-50% every time it shrinks by one percent. The relationship between 55Mpa, and the yield strength value required by the high yield strength finished copper flat wire, and the cross-sectional side length dimension to calculate the cross-sectional size of the semi-finished soft copper flat wire. 2. Preparation of flat copper wire in soft state: prepare flat copper wire in soft state according to the cross-sectional size determined in step a. The flat copper wire in soft state has a yield strength of 65-90 MPa and an elongation of 35-45%. The flat copper wire in soft state can be used directly by hot extrusion, or the flat copper wire drawn by a wire drawing machine can be fully annealed. 3. prepare finished co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com