Quick-release valve for charging liquid

A valve body and valve cover technology, applied in the field of large-diameter liquid-filled quick-release valves, can solve the problems of high power, increase production costs, waste energy, etc., and achieve the effects of reducing production costs, saving energy, and reducing oil intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

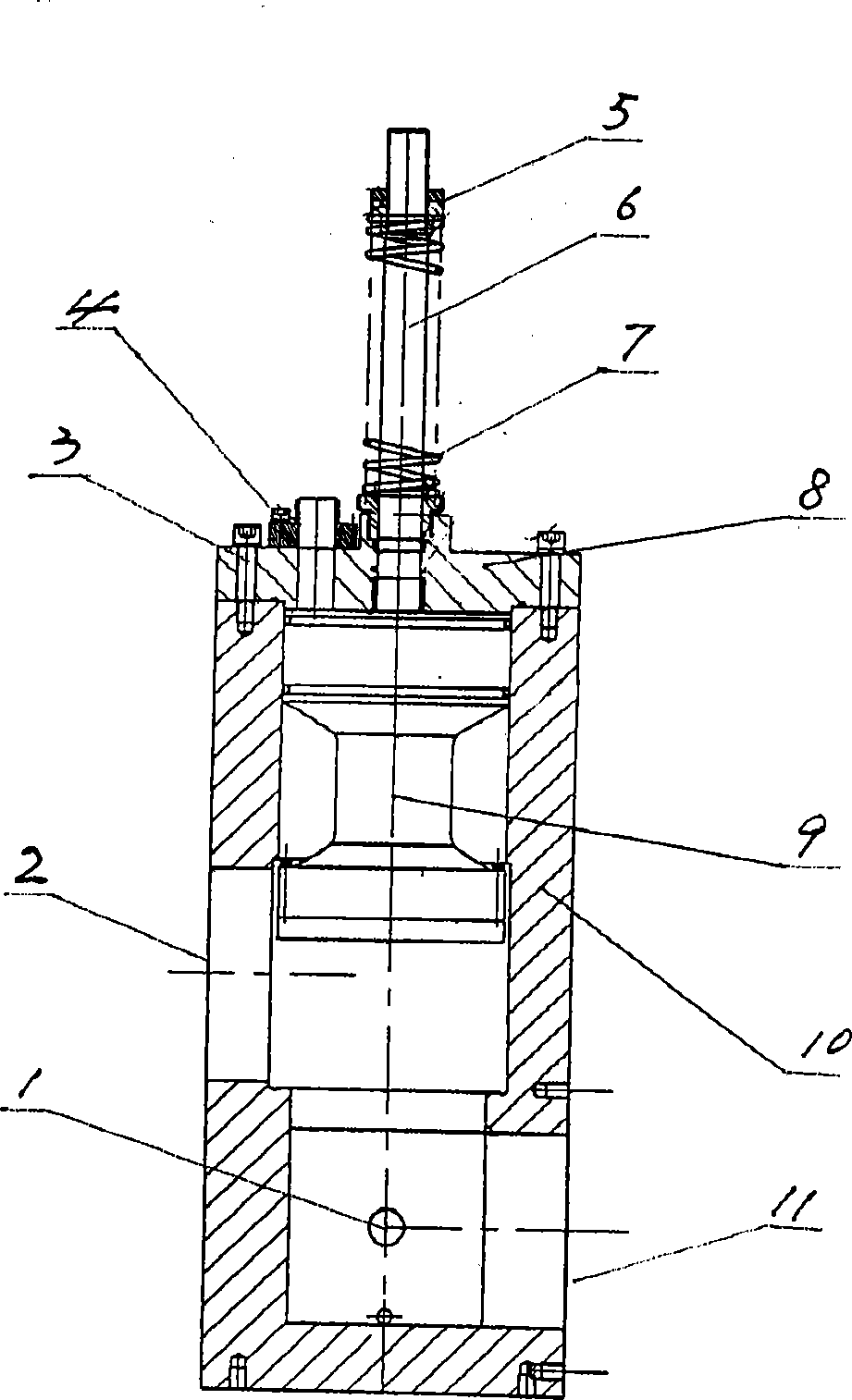

[0009] As shown in the drawings, the liquid-filled quick-release valve of the present invention includes a valve body 10, and the upper end of the valve body 10 is open to form a valve port. A valve cover 8 is arranged on the valve port, and the valve cover is fixed on the valve port by means of screws 3 . A center hole and a pressure relief hole 4 are processed on the valve cover 8; a valve core 9 is arranged inside the valve body 10, and a valve stem 6 is arranged on the upper end of the valve core 9. The lower end of the valve rod 6 is fixedly connected with the valve core 9, and its upper end passes through the central hole of the valve cover 8 and protrudes above the valve cover 8. The overhanging section of the valve stem 6 is covered with a spring 7, the outer end of the valve stem 6 is processed with an external thread and is equipped with a lock nut 5, and the upper and lower ends of the spring 7 are offset against the lock nut 5 and the valve cover 8 respectively. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com